Patents

Literature

31results about How to "Easy to mold at one time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

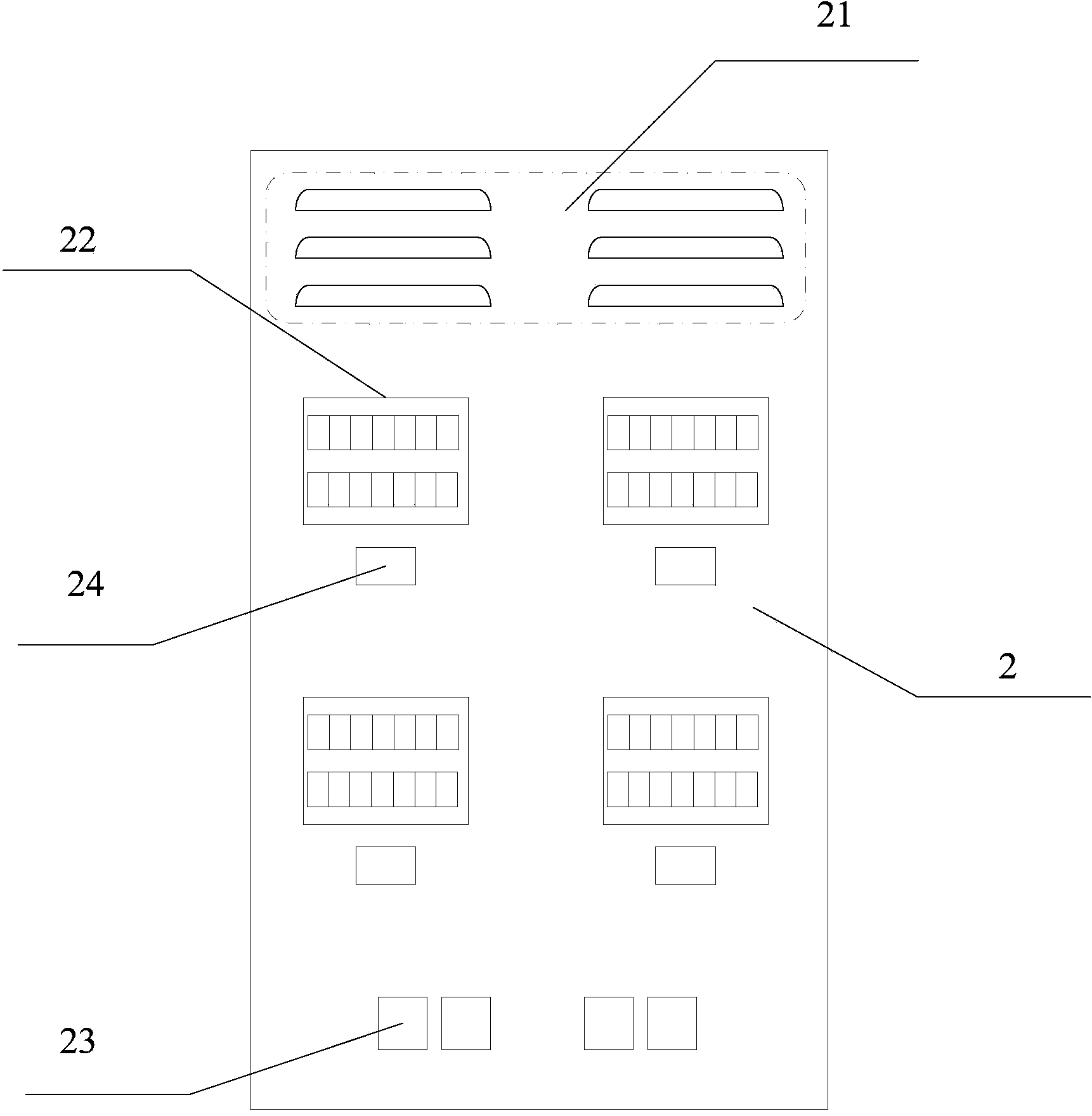

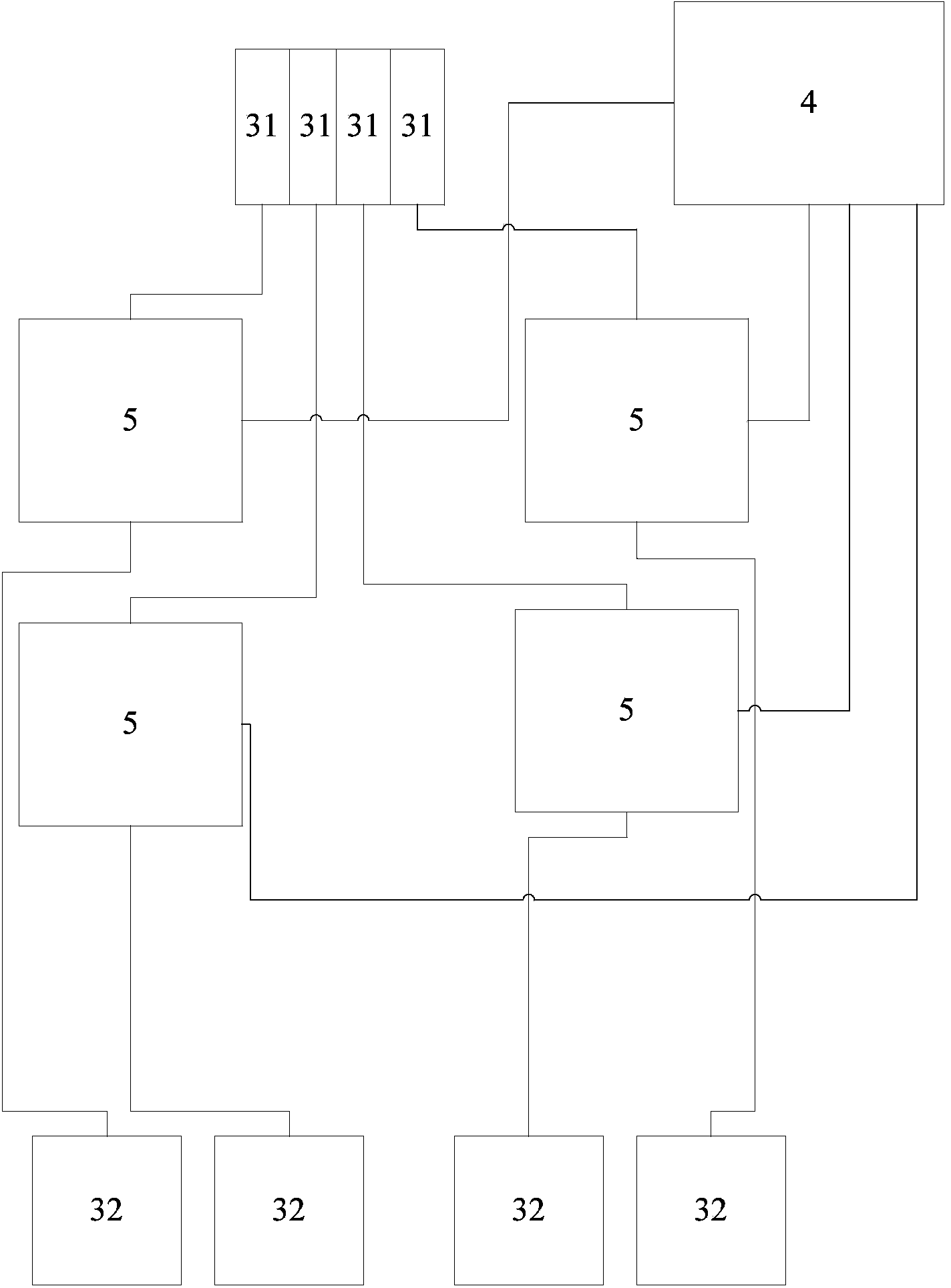

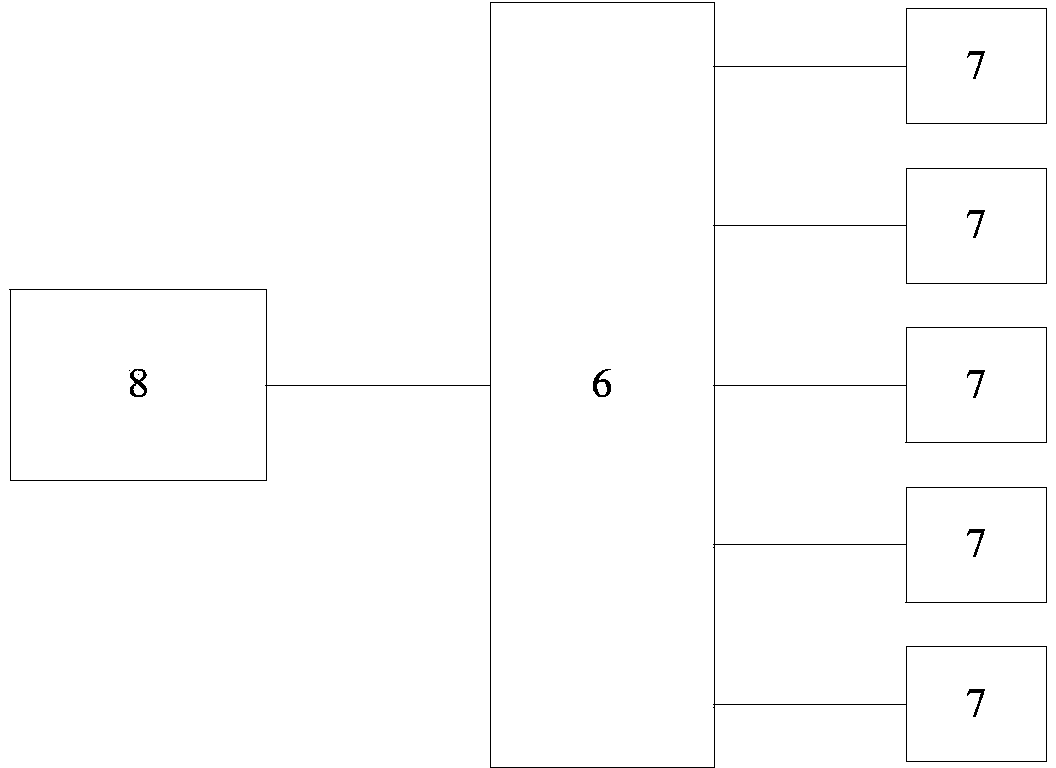

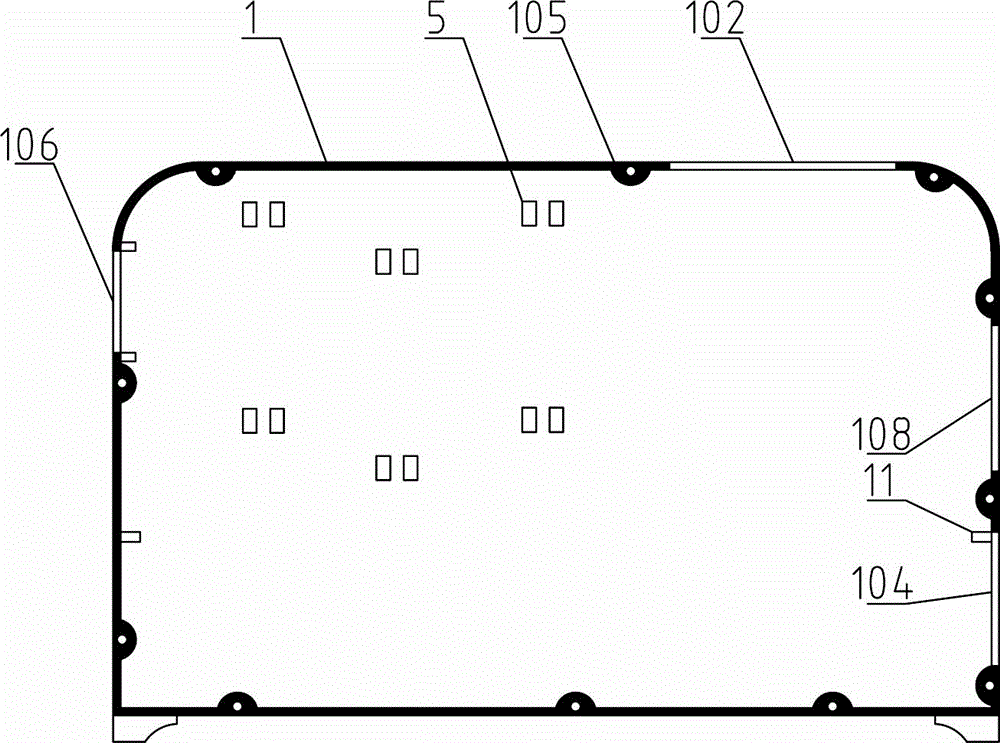

Single-phase and four-meter-position electric energy metering box

The invention relates to a single-phase and four-meter-position electric energy metering box. The single-phase and four-meter-position electric energy metering box comprises a box body, a box cover, four electric protection assemblies, collectors and four electric energy meters. Each electric protection assembly comprises a breaker in front of one meter and a breaker behind the meter, wherein the breaker in front of the corresponding meter, the electric energy meter and the breaker behind the meter are sequentially connected to form the electric energy meter assembly. The four electric energy meters are connected with the collectors respectively; the collectors are connected with a remote terminal through a concentrator; the collectors collect electric pulse signals of the four electric energy meters, convert the electric pulse signals into digital data information and transmit the digital data information to the concentrator; the concentrator gathers the data information of all the collectors and transmits the data information to the remote terminal; the electric protection assemblies protect electric equipment against damage. Compared with the prior art, the single-phase and four-meter-position electric energy metering box has the advantages of being intelligent in meter reading, unified in specification to lower the cost, and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

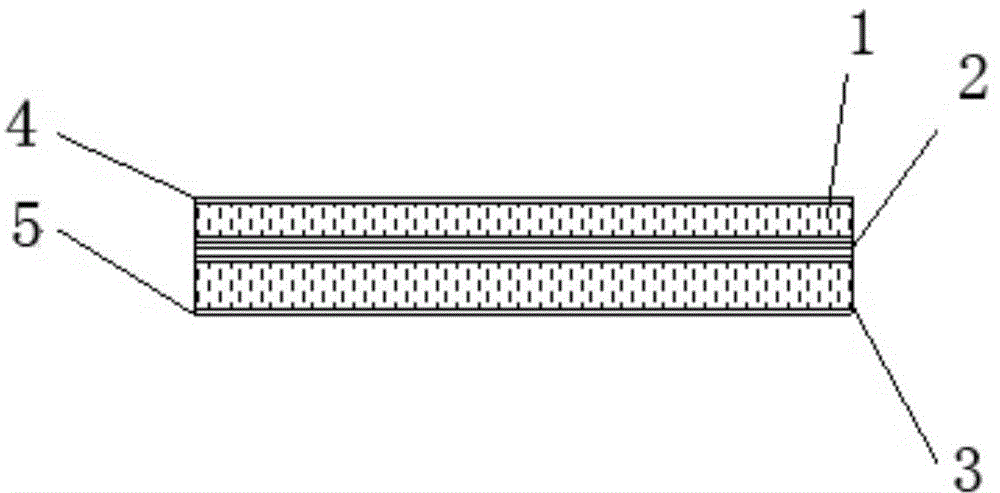

Carbon fiber microchip reactor

ActiveCN103551096ALight in massImprove corrosion resistanceChemical/physical/physico-chemical processesFiberCarbon fibers

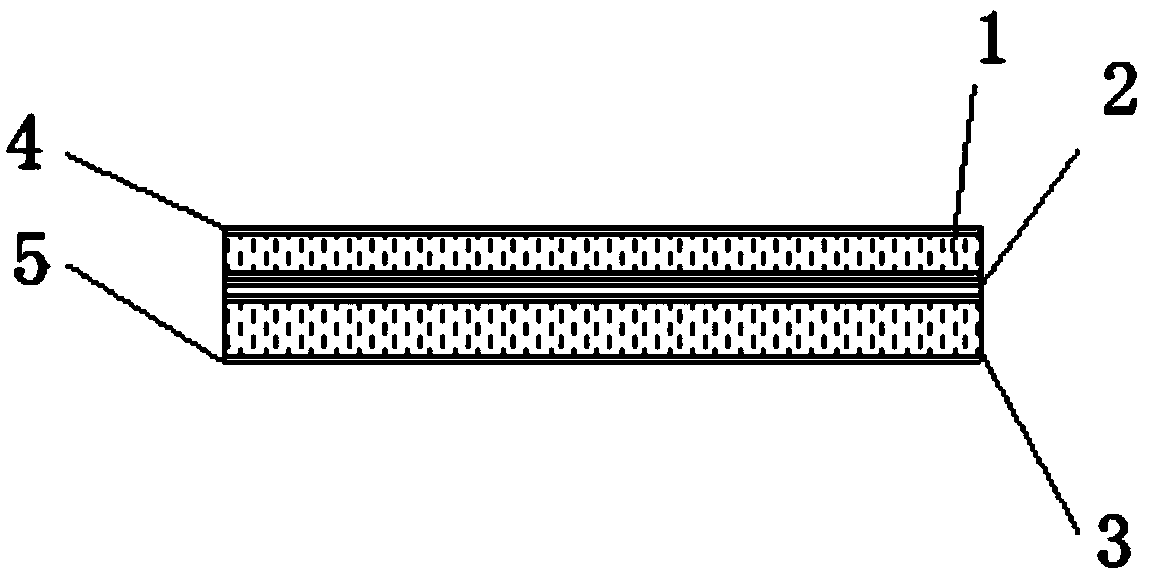

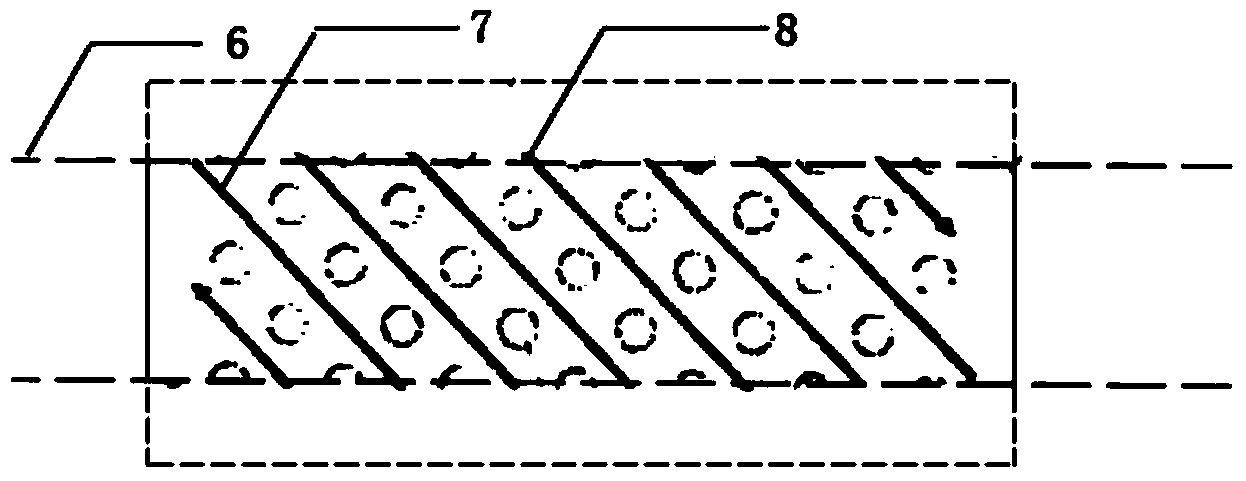

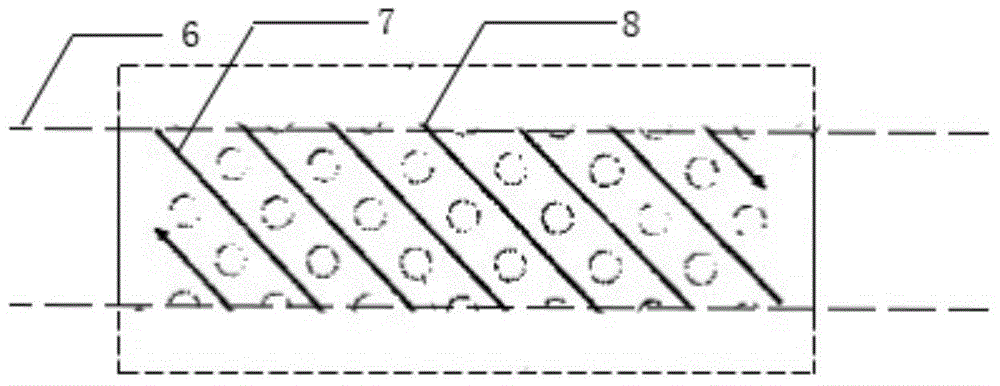

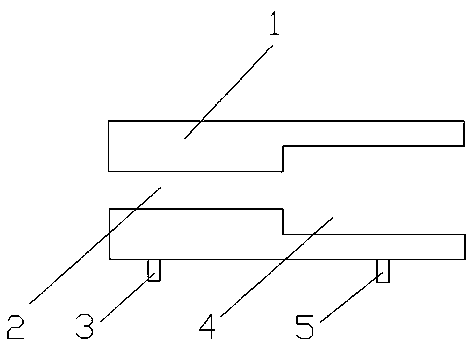

The invention discloses a carbon fiber microchip reactor. The carbon fiber microchip reactor is a multi-layer structure, and comprises a heat conducting or electricity conducting layer, an upper-layer carbon fiber blanking plate, a carbon fiber reaction channel layer, a lower-layer carbon fiber blanking plate and a second heat conducting or electricity conducting layer sequentially from top to bottom, wherein the carbon fiber reaction channel layer comprises a micro-channel for chemical reaction of fluid; the carbon fiber reaction channel layer, the upper-layer carbon fiber blanking plate and the lower-layer carbon fiber blanking plate are all made of carbon fiber plates. The carbon fiber microchip reactor has the following advantages: 1. the reactor has light weight and is portable; 2. the reactor has extremely high corrosion resistance and can resist acid and base; 3. the reactor has ultra high heat conducting property; 4. the reactor can be formed in one time conveniently, so that the mass production is realized, and the requirement of equipment of development tendency of a chemical process in future is met.

Owner:NANJING UNIV OF TECH

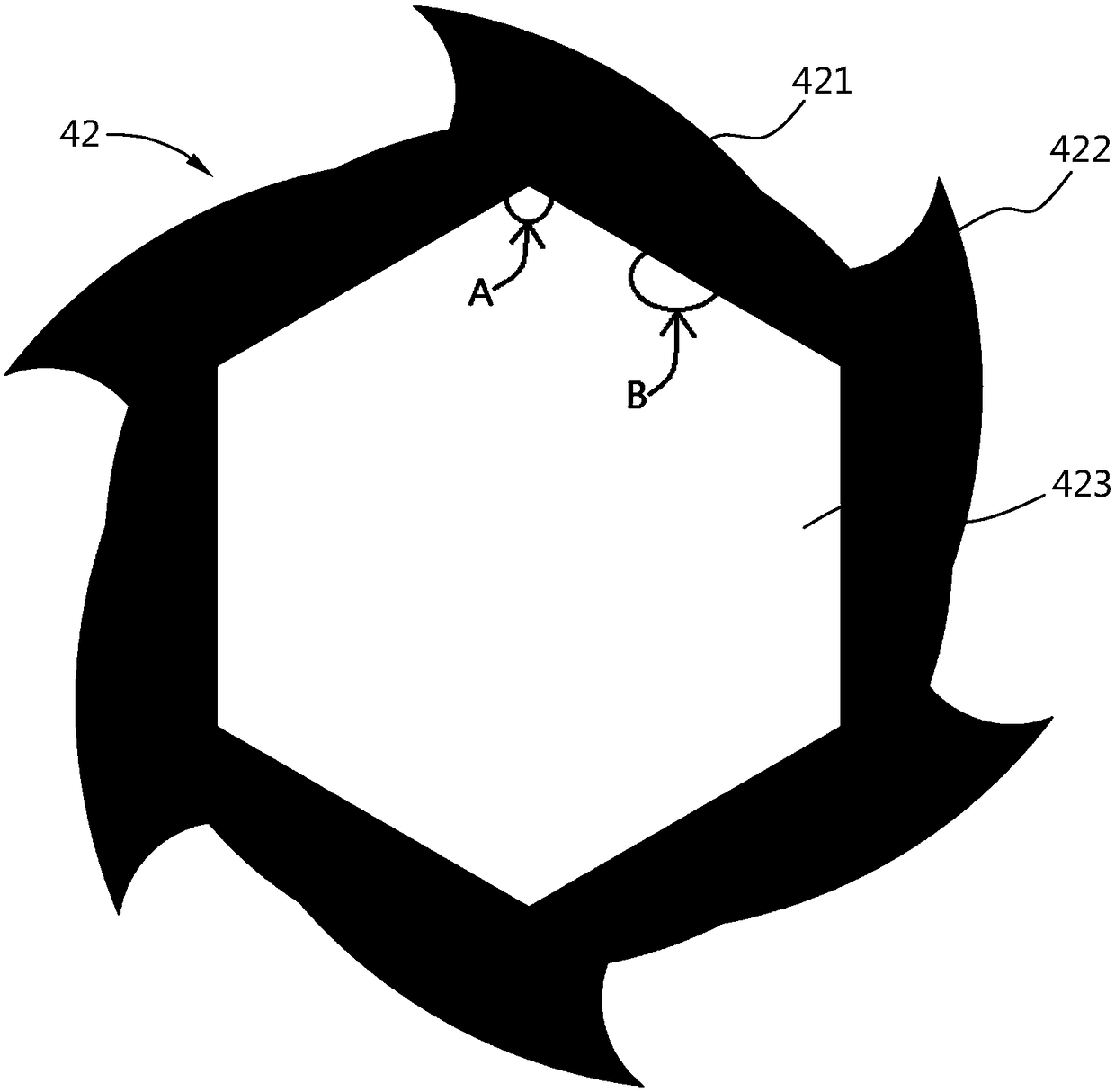

Combination cutter

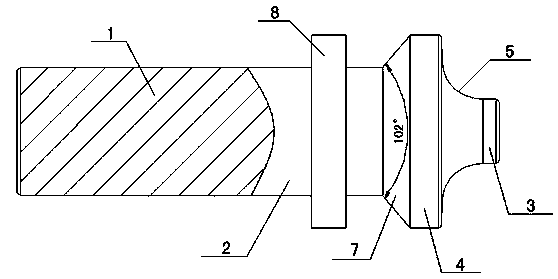

InactiveCN103752927AAvoid multiple chamfering problemsEasy to mold at one timeMilling cuttersBonded abrasive wheelsEngineeringGrinding wheel

The invention relates to a combination cutter. The combination cutter comprises a cutter handle and a cutter bit; one end of the cutter handle is connected to one end of a supporting rod by welding; the right end surface is an arc-shaped convex surface; the left end surface of the supporting rod is an arc-shaped concave surface adapting to the arc-shaped convex surface; the cutter bit is connected to the other end of the supporting rod; the cutter bit comprises a front cutting part, a rear cutting part and a bevel cutting part; one end of the bevel cutting part is at an taper angle of 102 degrees and is connected with the supporting rod, and the other end of the bevel cutting part is connected with one end of the rear cutting part; the front cutting part is connected with the rear cutting part through an arc-shaped cutting part; a grinding wheel is arranged in the middle part of the supporting rod; and the grinding wheel has the outer circle diameter the same as that of the rear cutting part. The combination cutter is able to perform milling and grinding once, so that the time is saved, and the efficiency is improved.

Owner:常州市恒晁工具制造有限公司

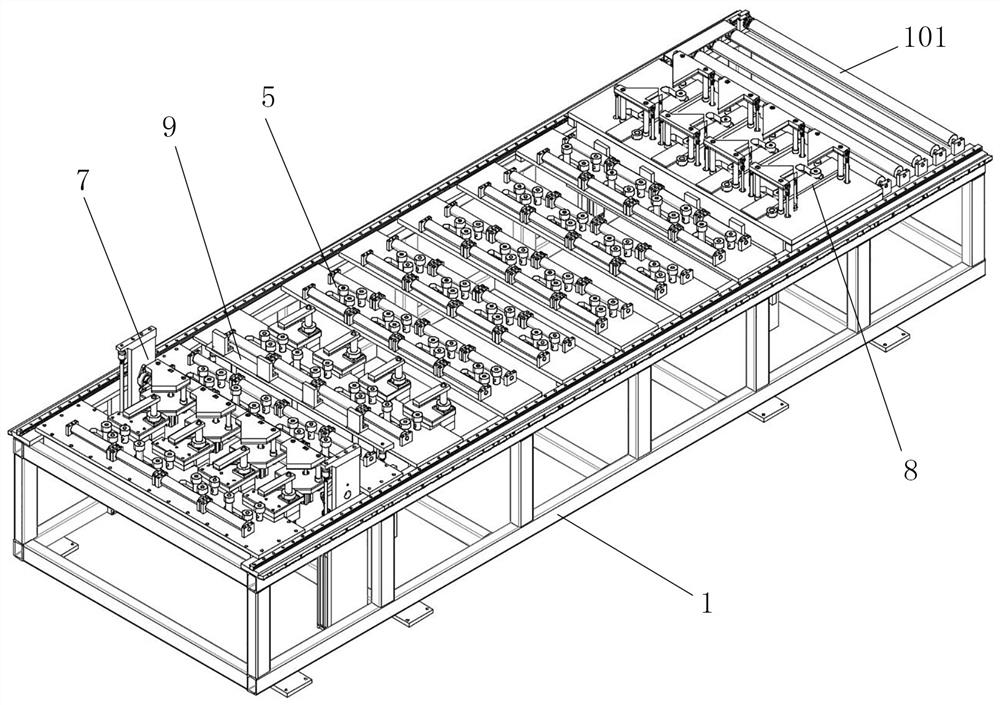

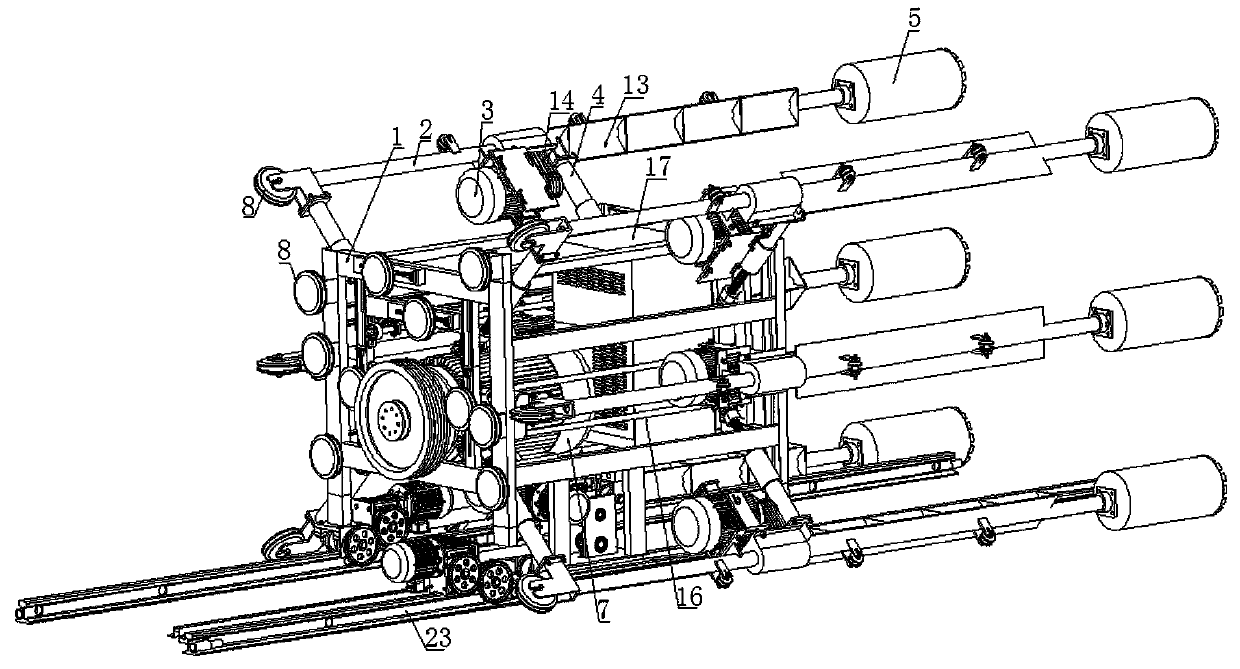

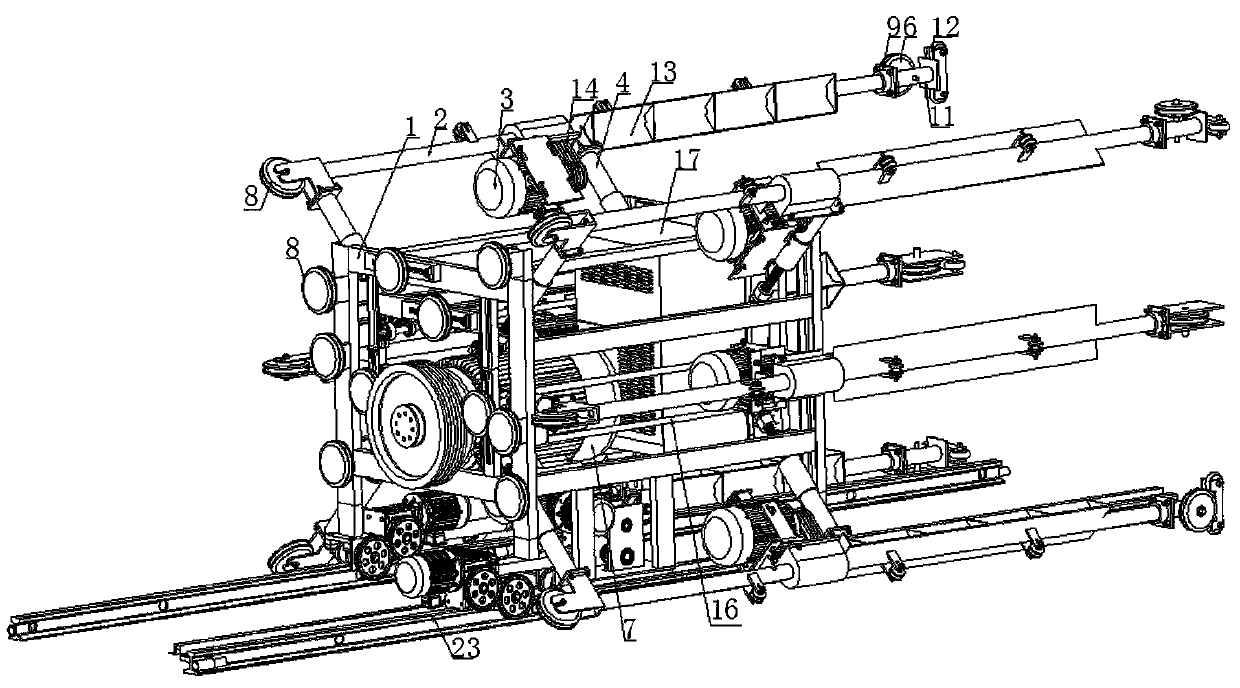

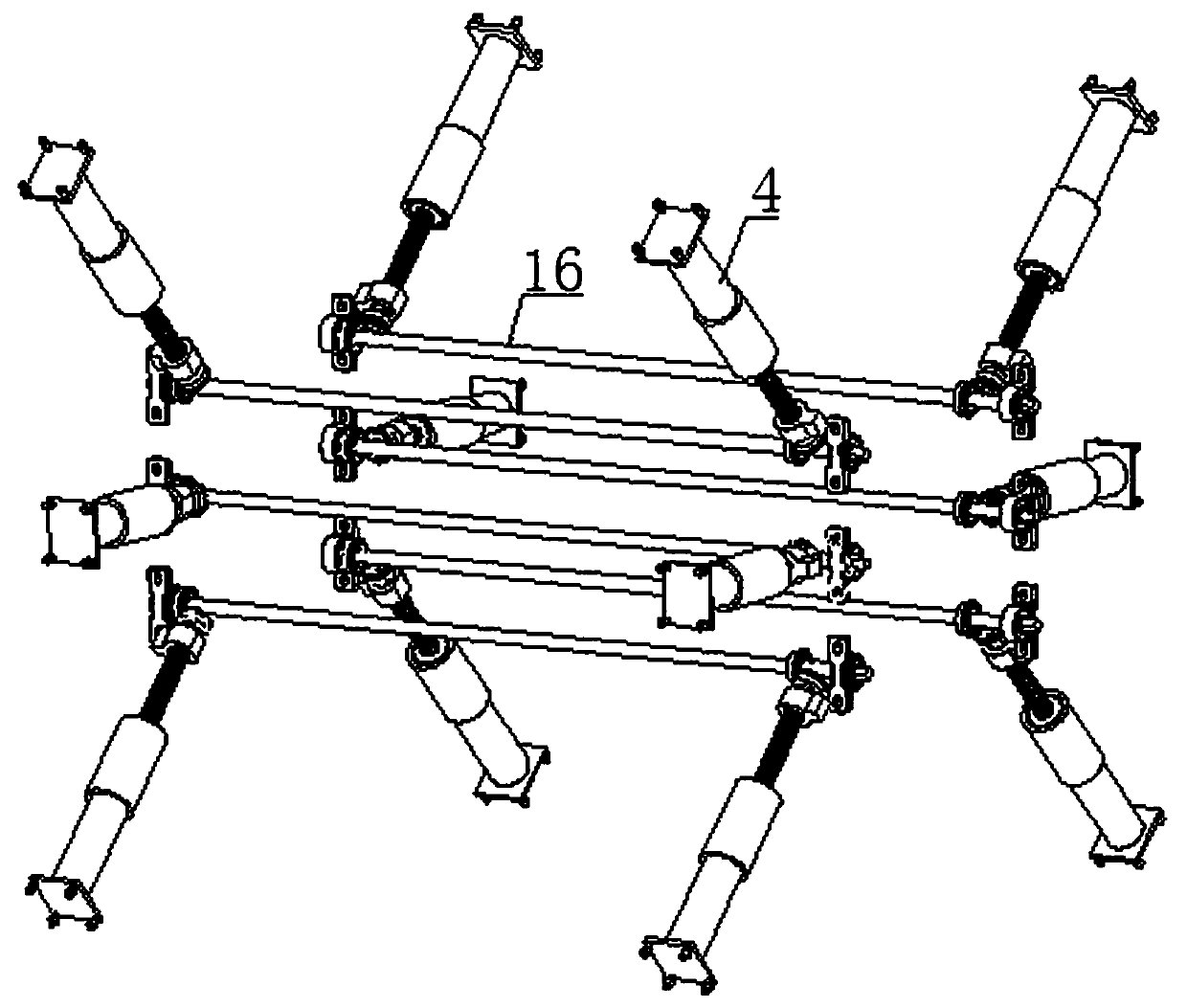

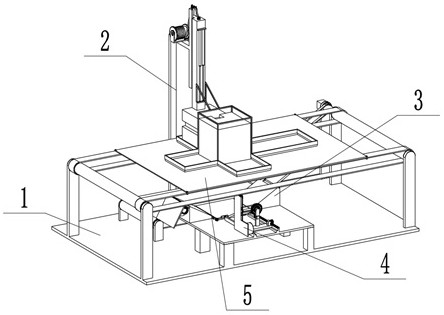

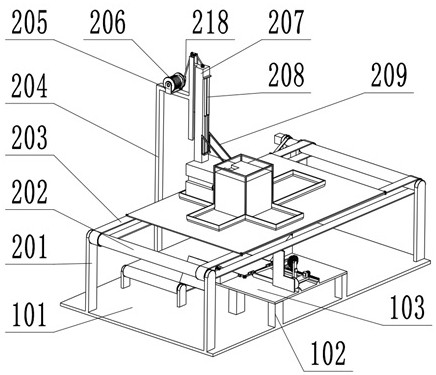

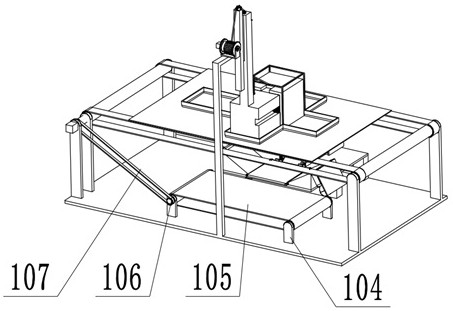

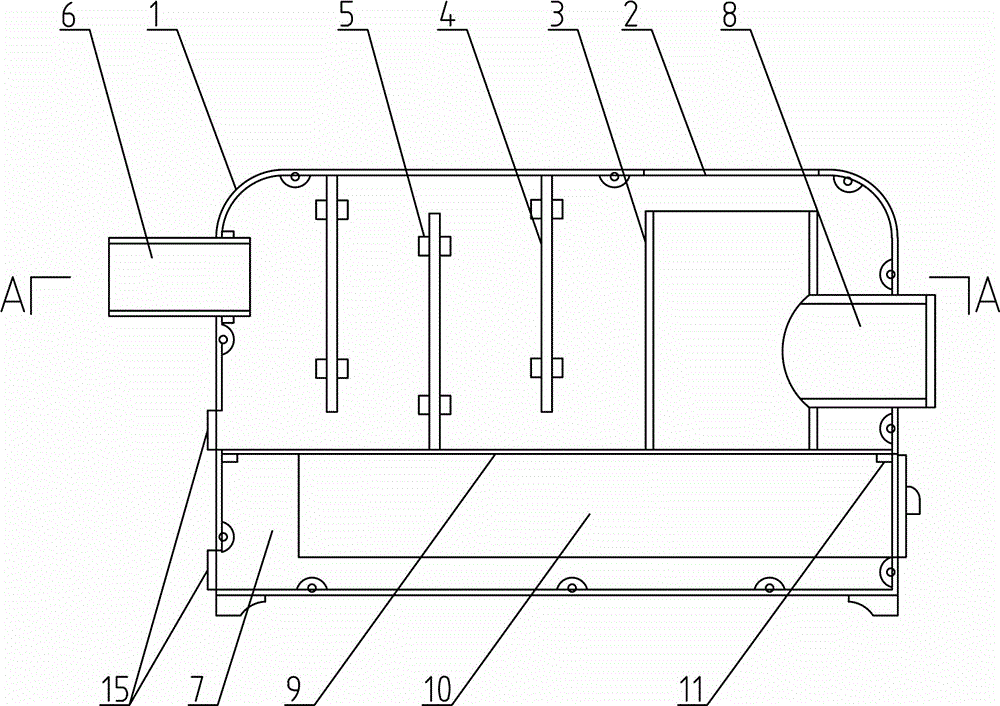

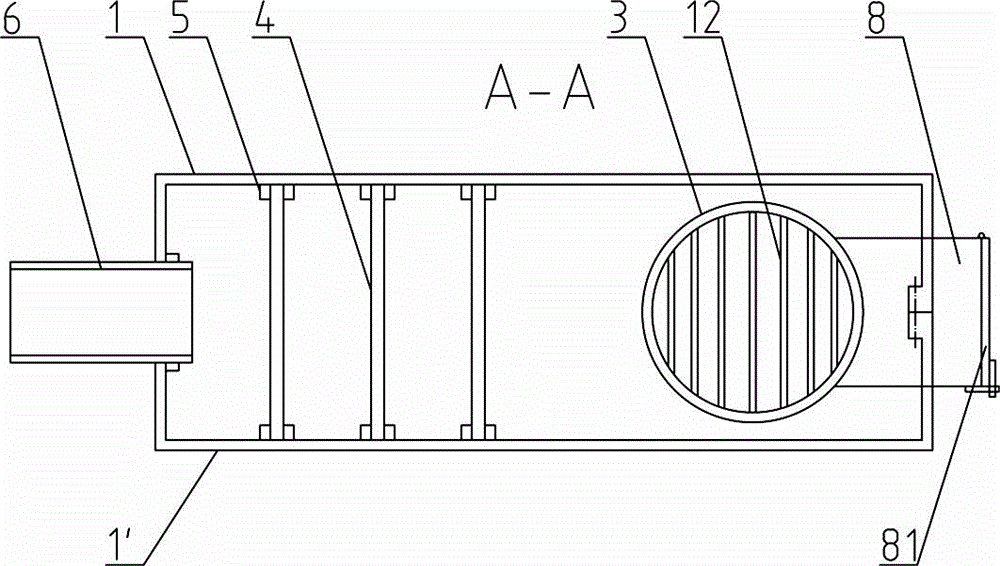

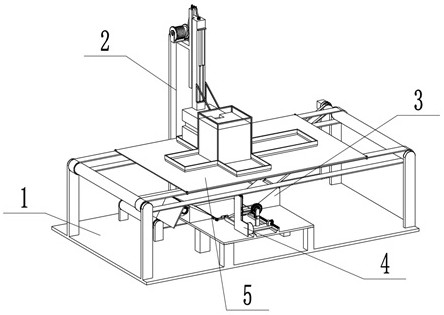

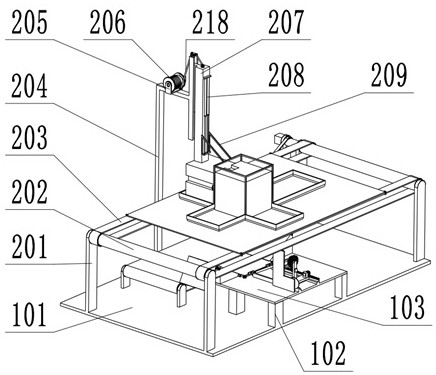

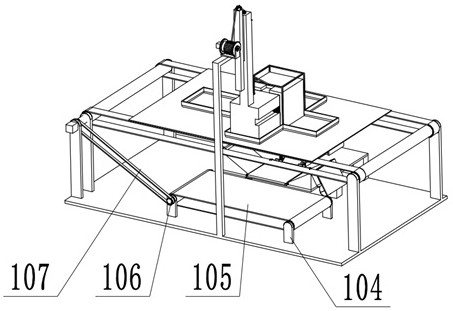

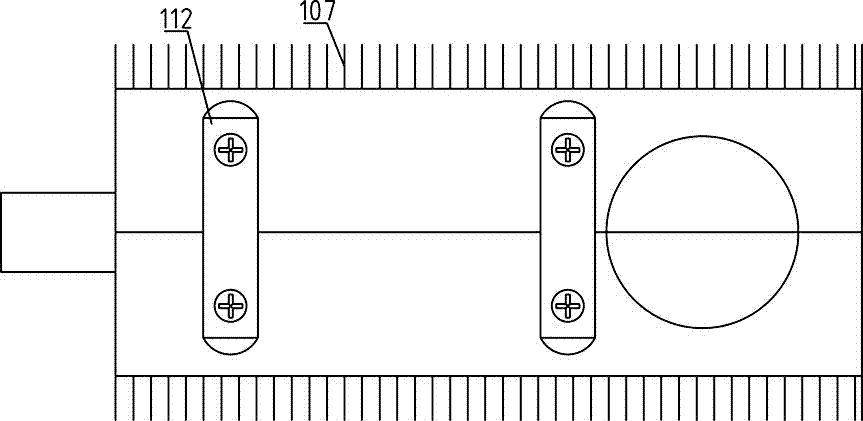

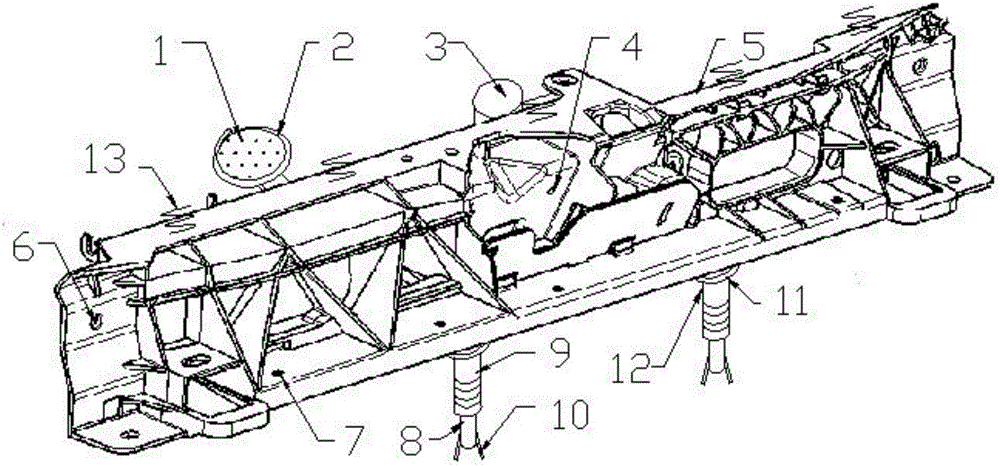

Automatic cutting device for aluminum profile processing

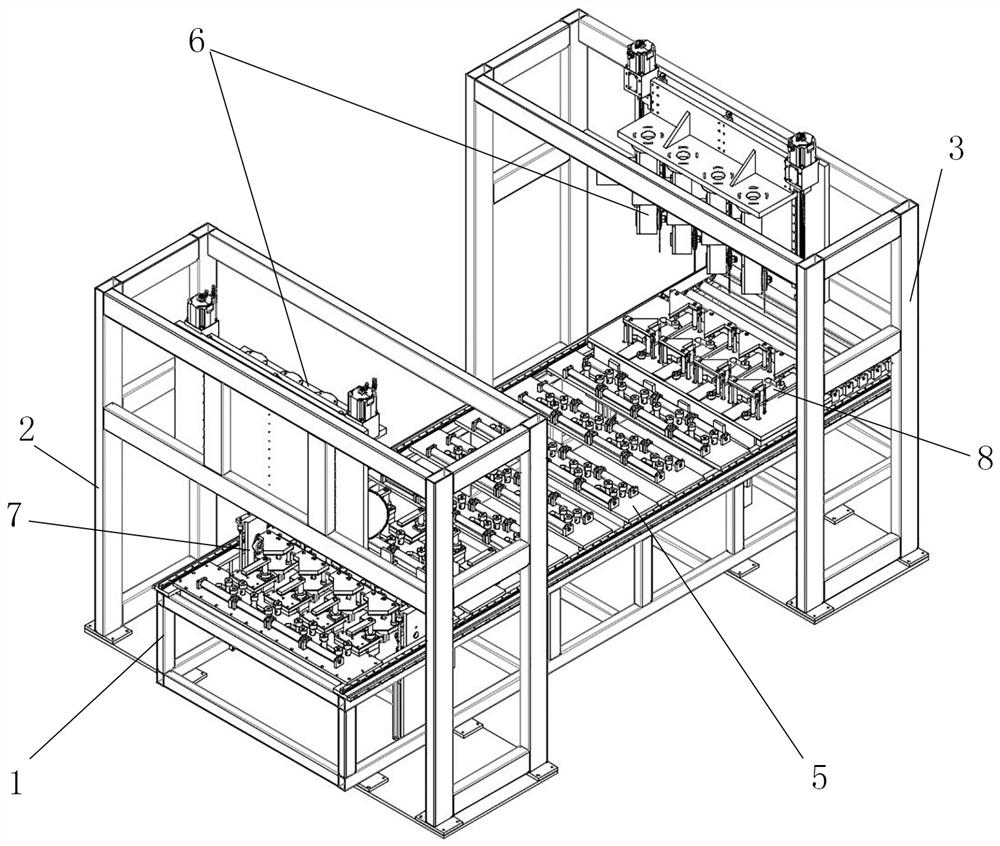

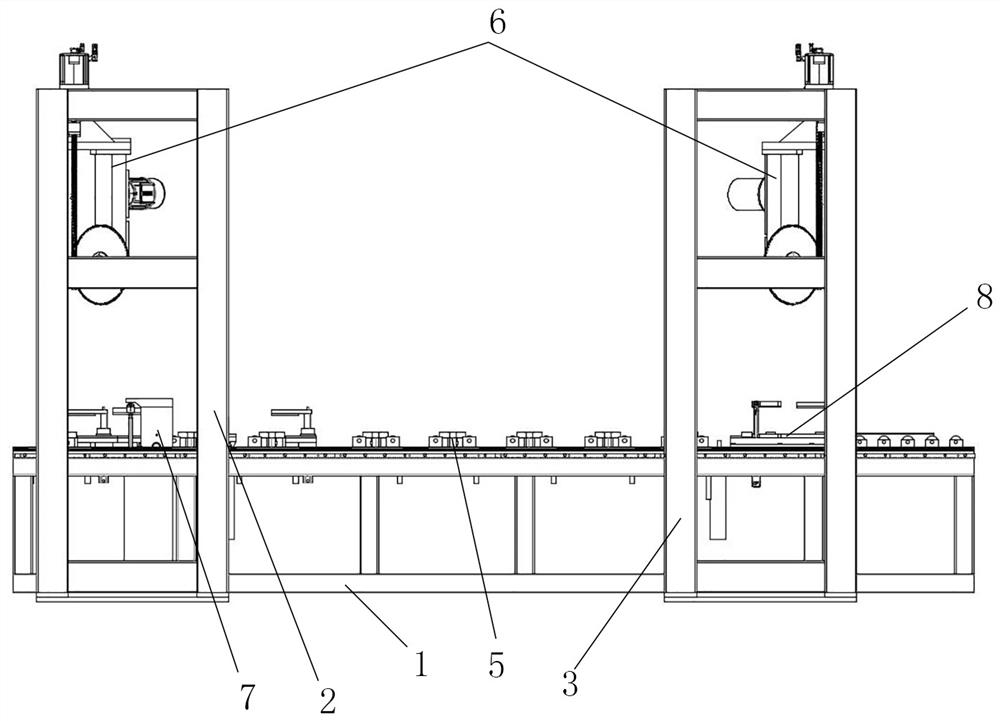

PendingCN111687482AAvoid wastingEasy to adjust the orientationMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention relates to the technical field of aluminum profile processing equipment, and in particular relates to an automatic cutting device for aluminum profile processing. The automatic cutting device comprises a conveying frame, an end cutting frame, a cutting frame and a material pushing vehicle. Multiple aluminum profiles are placed on the conveying frame and are supported and clamped respectively by multiple supporting and clamping mechanisms to the state parallel to a processing and conveying direction. After the multiple aluminum profiles are clamped and adjusted by a clamping mechanism on the material pushing vehicle to a state of being flat at the end, the aluminum profiles are driven to move and adjust in the length direction of the conveying frame, and the front ends of thealuminum profiles are cut by a cutting piece on the end cutting frame at the end cutting frame. After the aluminum profiles are driven by the material pushing vehicle to move for a long certain length, the aluminum profiles are cut by a cutting piece on the cutting frame at the cutting frame. The cutting pieces on the cutting frame and the end cutting frame can be adjusted so that the length and the deflections of the two end faces of the cut aluminum profiles meet the requirements. The production efficiency is greatly improved.

Owner:河南欣柯奕舟重工科技有限公司

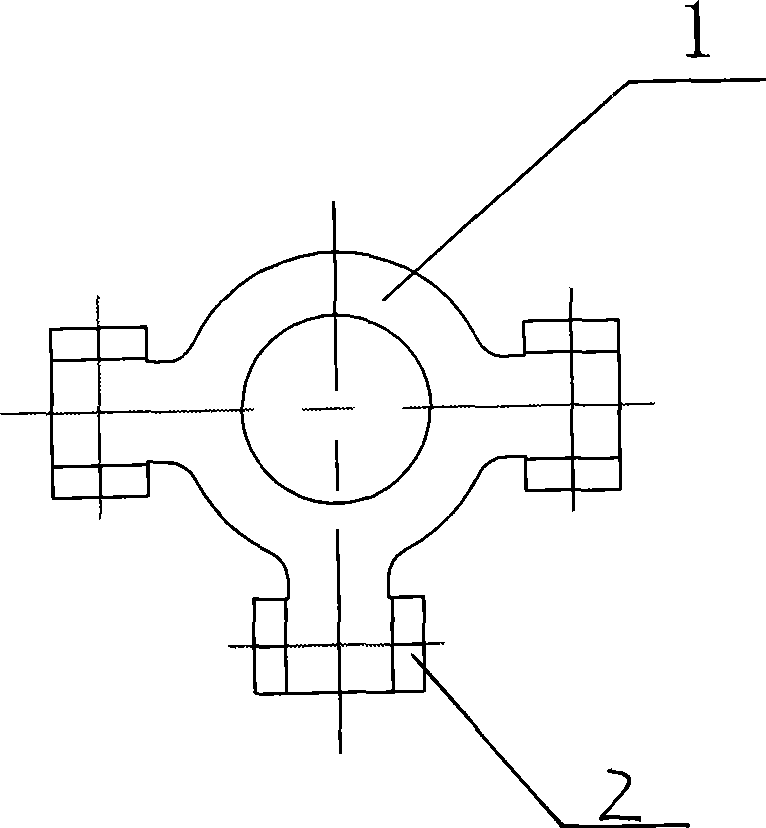

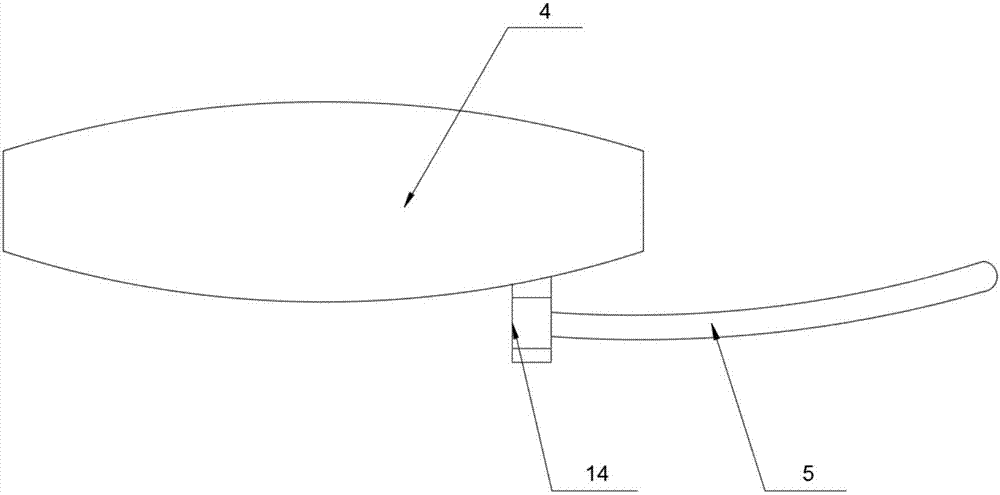

Power divider and application method thereof

InactiveCN101533942AGuaranteed not to be connectedSolve the defects of third-order intermodulationCoupling devicesElectrical conductorCable line

The invention discloses a power divider and an application method thereof, wherein the power divider body of the power divider is in plate-shaped ring type and three antennas are distributed equally at the external edge of the power divider body. Three antennas of the power divider are respectively welded with cable conductors fixedly by homogeneous materials, and a cable inner conductor is welded at the upper part of the plate-shaped ring-type hollow part, with a welding point positioned just at the ring-type hollow part of the power divider, thus ensuring the convenient welding of the cable inner conductor and the disconnection between the inner conductor and an external conductor simultaneously.

Owner:JIANGSU HUACAN TELECOMM

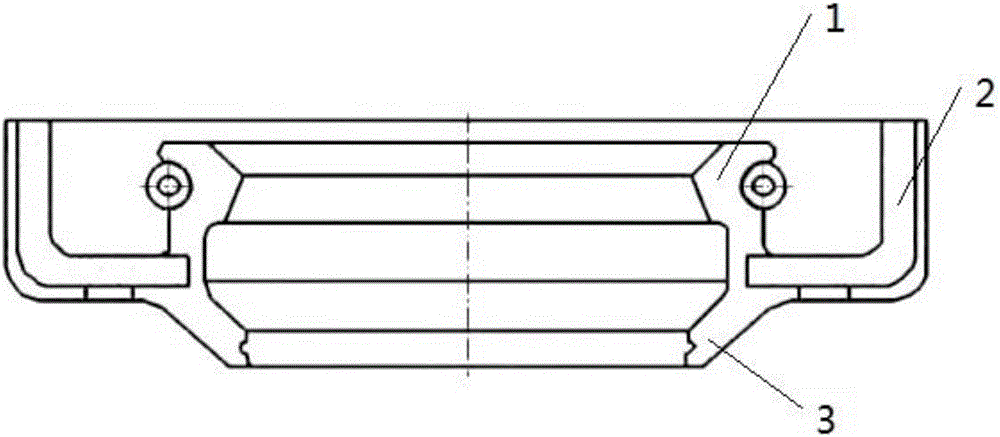

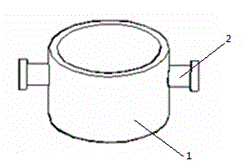

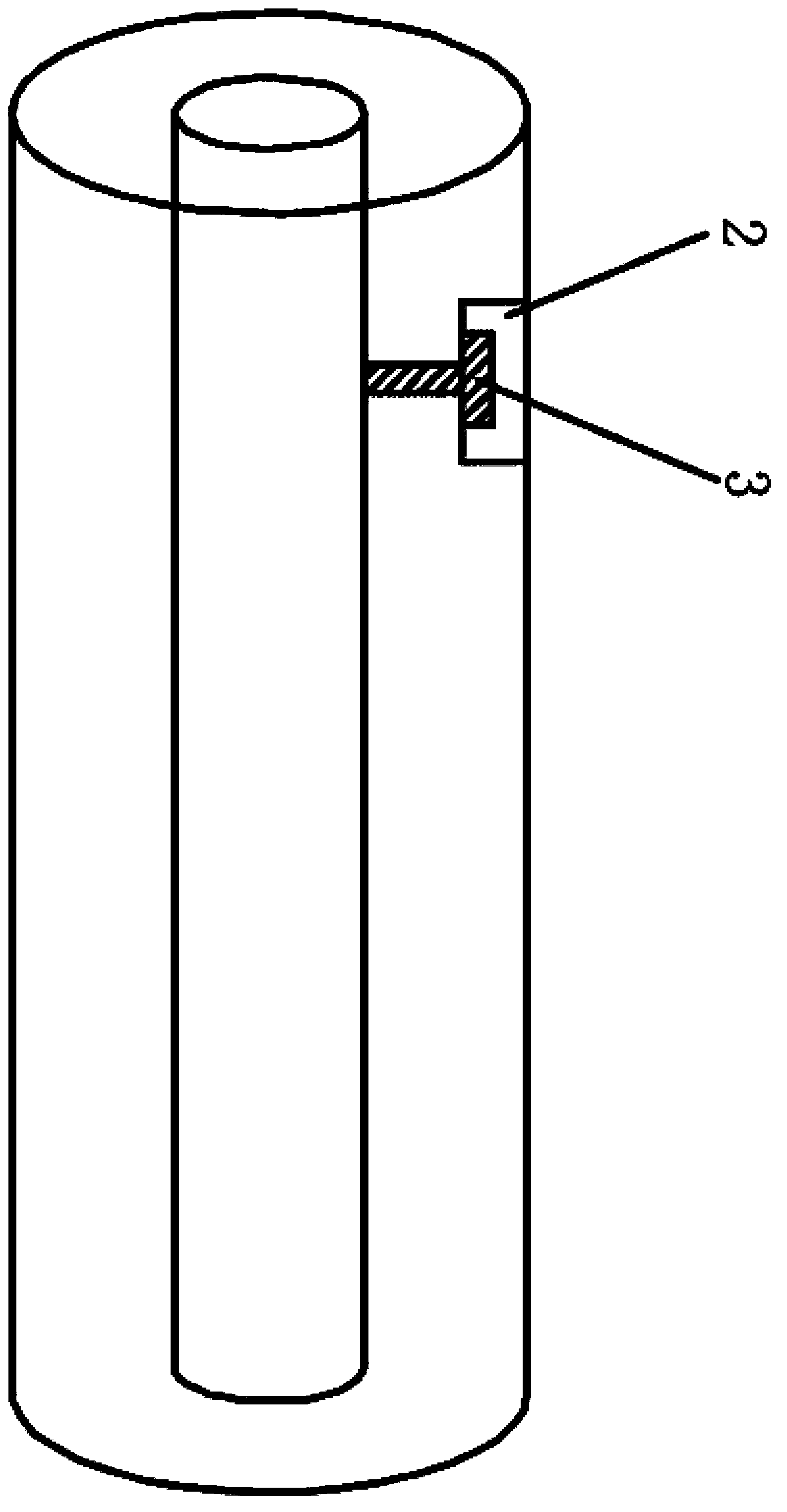

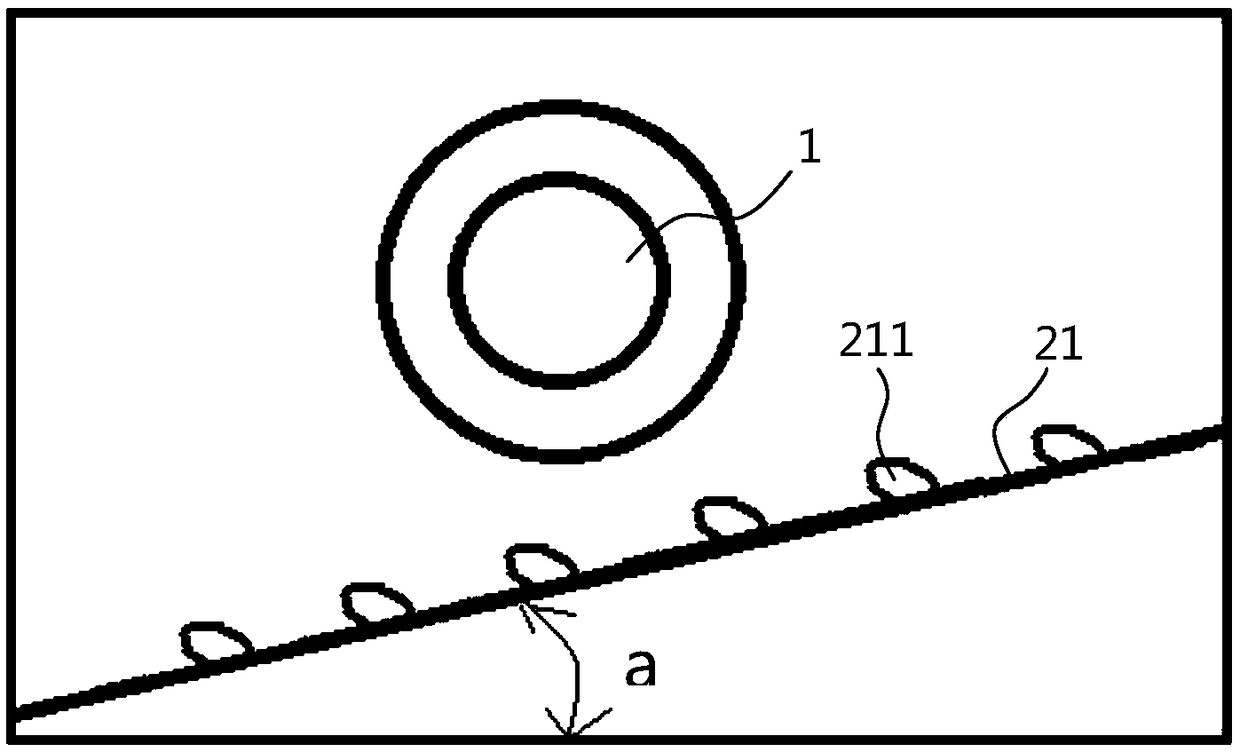

Rubber sealing ring

The invention discloses a rubber sealing ring. The rubber sealing ring comprises an annular skeleton 2, a silica layer, an inner sealing ring 1 and an outer sealing ring 3, wherein the section shape of the annular skeleton 2 is L-shaped; the outer side of the annular skeleton 2 is coated with the silica layer; the inner sealing ring 1 and the outer sealing ring 3 are arranged on the inner side of the annular skeleton 2; the silica layer, the inner sealing ring and the outer sealing ring are integrally formed; the silica layer, the inner sealing ring and the outer sealing ring are formed by mixing the following raw materials in parts by weight: 100 parts of raw rubber, 20 to 25 parts of an active agent, 5 parts of a plasticizer, 3 parts of an anti-ageing agent, 10 parts of a reinforcing agent, 10 parts of a plasticizer, 5 parts of an accelerant and 1 part of a vulcanizing agent; the inner sealing ring and the outer sealing ring are arranged on the inner side and the outer side of the L-shaped skeleton correspondingly; the inner sealing ring realizes oil seal and the outer sealing ring realizes gas seal; meanwhile, the inner sealing ring and the outer sealing ring adopt rubber materials with high oil resistance, have high surface polarity and high stability, are insusceptible to swelling, and meet the requirements of oil seal and gas seal.

Owner:东莞市瑞拓五金橡塑有限公司

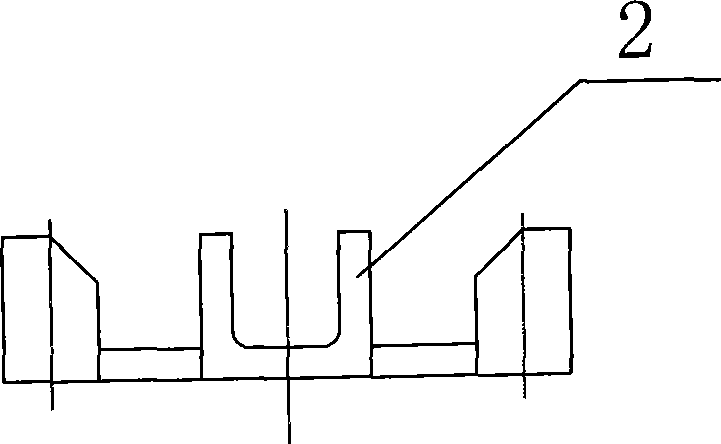

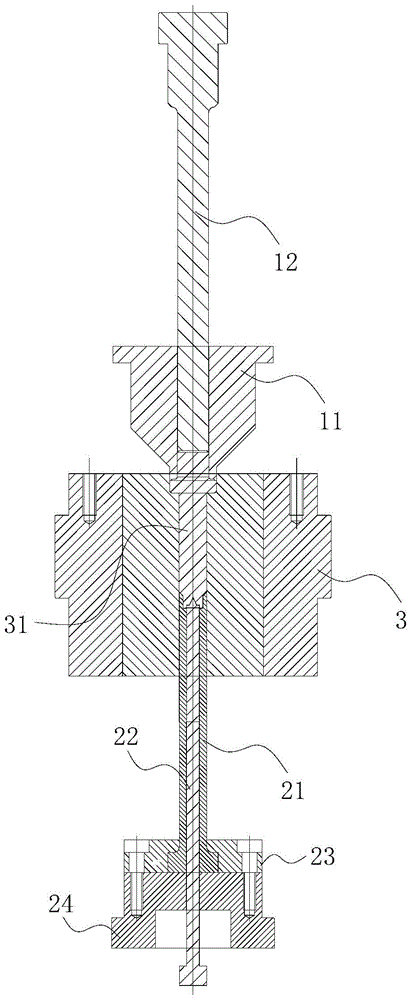

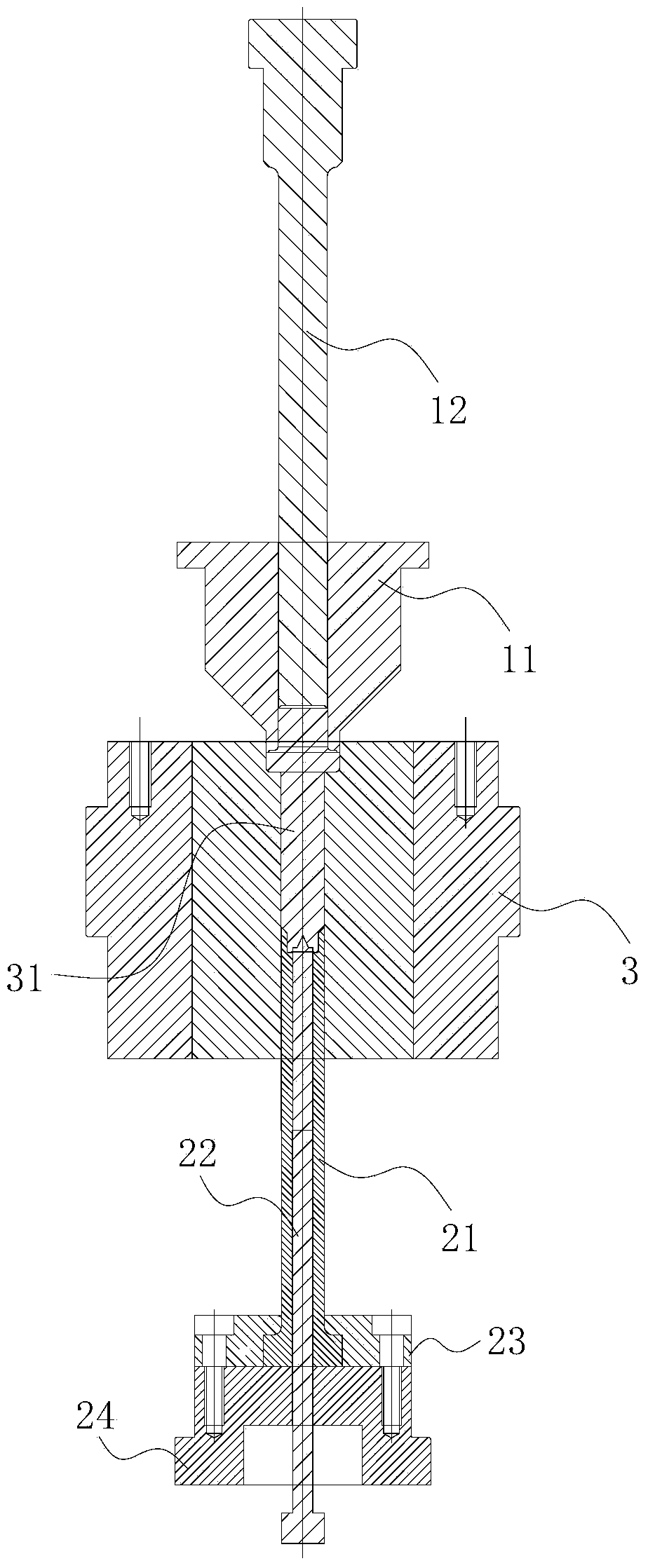

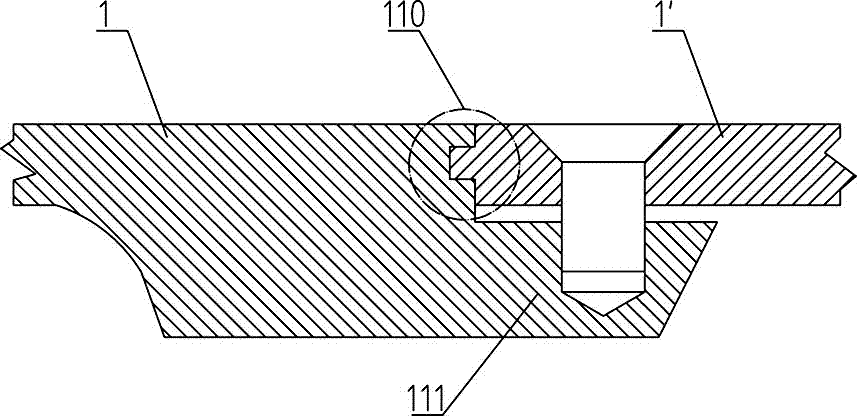

A powder metallurgy pressing die for output shaft

The invention discloses a powder alloy pressing mold used for an output shaft. The powder alloy pressing mold comprises an upper mold body and a lower mold body, and further comprises a middle mold body arranged between the upper mold body and the lower mold body. A mold cavity of the middle mold body is filled with metal powder used for molding the output shaft. The upper mold body comprises an upper guide sleeve and a pressing rod, wherein a square end opening is formed in one end of the upper guide sleeve, the pressing rod is matched with a square through hole axially formed in the axis of the upper guide sleeve, and one end of the upper guide sleeve is matched with the upper end of the mold cavity of the middle mold body; the lower mold body comprises a lower guide sleeve and an ejector rod, wherein four long grooves are axially and evenly formed in the circumferential wall of an end opening in one end of the lower guide sleeve, the ejector rod is matched with a circular hole axially formed in the axis of the lower guide sleeve, and one end of the lower guide sleeve is matched with the lower end of the mold cavity of the middle mold body. As the upper mold body is matched with the lower mold body, complex structures at the two ends of the output shaft can be conveniently molded, the secondary machining trouble is saved, the powder alloy pressing mold brings convenience to one-time molding of the output shaft, and the machining accuracy and the production efficiency are high.

Owner:TAICANG JINLIDE POWDER METALLURGY

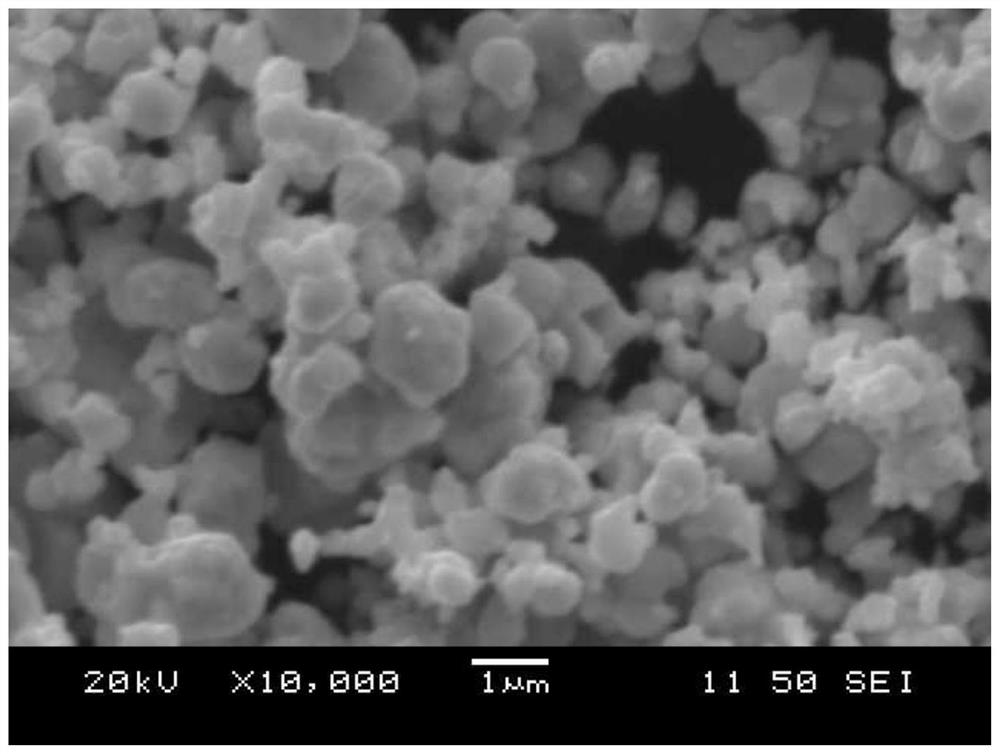

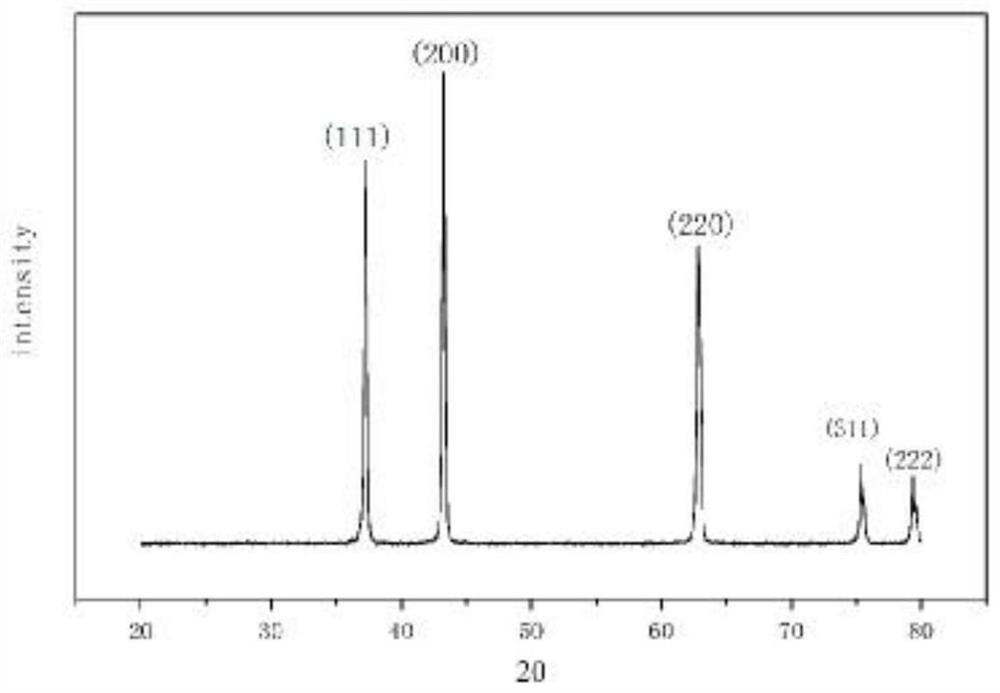

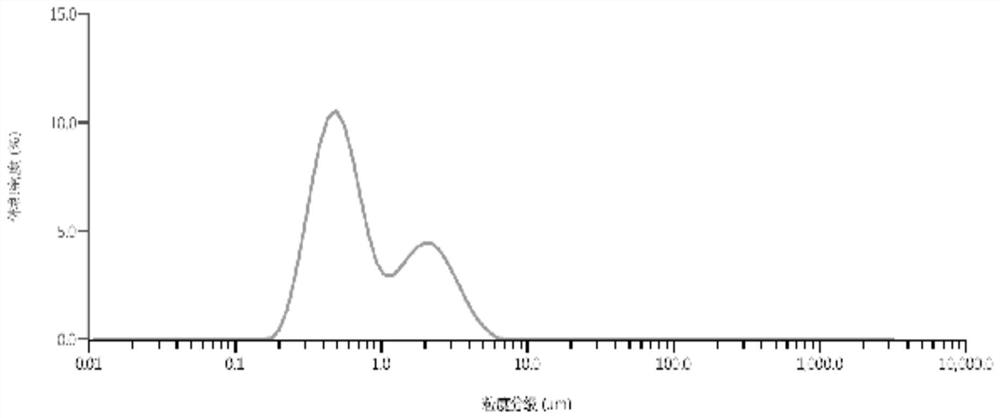

Hot isostatic pressing preparation method of nickel oxide-based ceramic target material

InactiveCN112441819AImprove conductivityHigh densityAuxillary shaping apparatusMetallurgySpray dried

The invention relates to a hot isostatic pressing preparation method of a nickel oxide-based ceramic target material. The method comprises the following steps: A, performing raw material preparation:preparing mixed powder of nickel oxide powder and doped source powder, the total mass fraction of doped source elements in the mixed powder not being higher than 10%, and the doped source being selected from one or more of Li, Na, Mg, Al, Si, K, Zn, Zr, Mn, Cu, Cr, V, W and Ti, the purity of the nickel oxide powder and the doping source powder being higher than 99.99%, the average particle size being 500 nm-2 microns, and the D50 particle size is 50 nm-800 nm; B, performing spray drying; C, loading the product into a sheath mold; D, performing vacuum degassing; E, performing hot isostatic pressing treatment, specifically, the pressure intensity being 50-200 MPa, the sintering temperature being 500-1200 DEG C, the heat preservation time being 1-5h, and the temperature rising speed being 0.5-3 DEG C / min; F, obtaining a sintered blank; and G, carrying out machining or not carrying out machining according to needs to reach the designed size to obtain a target material finished product.

Owner:北京航大微纳科技有限公司

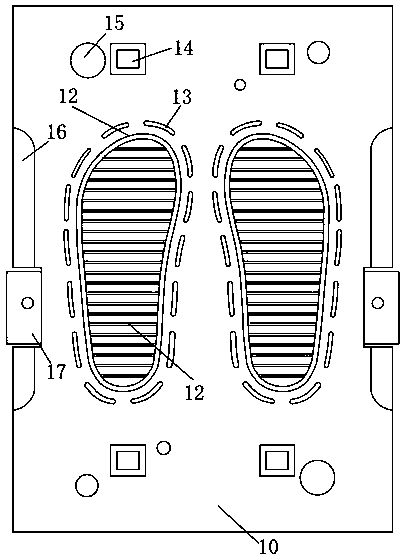

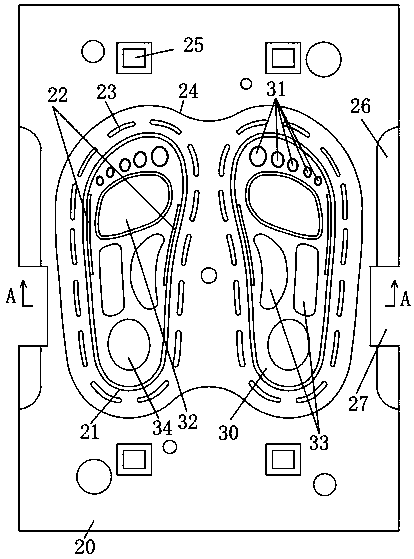

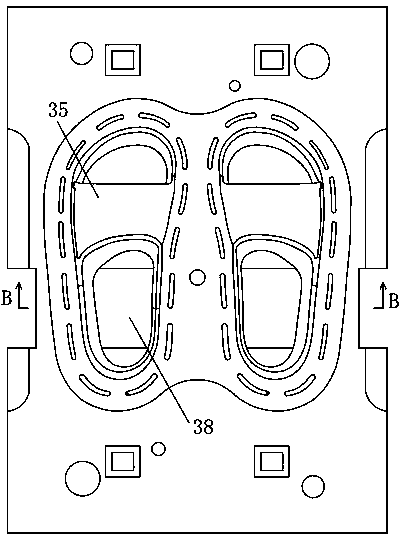

EVA in-mold bubble one-time forming mold and forming method

The invention relates to an EVA in-mold bubble one-time forming mold and a forming method. Foot-shaped inserts matched with lower mold cavities to form sole bulges are arranged on a lower mold plate,five protruding blocks used for forming an anti-skid concave face are arranged on the areas, corresponding to the toe portions of a foot, of the upper surface of each foot-shaped insert, first concavecavities are formed in the area, corresponding to the forefoot part of the foot, of the upper surfaces of the foot-shaped inserts, second concave cavities are formed in the inner side and the outer side of the area, corresponding to the arch part of the foot, of the upper surfaces of the foot-shaped inserts correspondingly, third concave cavities are formed in the area, corresponding to the heelpart of the foot, of the upper surfaces of the foot-shaped inserts, and arc-shaped concave parts matched with the lower mold cavity to form upper forming channels are arranged on the foot-shaped inserts. The forming mold is conveniently used for one-time forming of shoes made of EVA materials.

Owner:莆田市万鑫模具有限公司

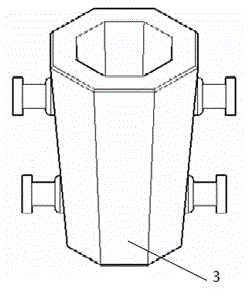

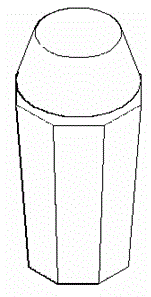

Manufacturing device of 1500kg eight-square ingot model

The invention provides a manufacturing device of a 1500kg eight-square ingot model. The device comprises a mold and a cap section; according to the cap section, the outer wall is in an annular shape, an inner cavity is in a round table shape, the height is 24cm, and two lifting handles are symmetrically arranged on the outer side face; the outer wall of the mold and the surface of the inner cavity are both in top-pruning right eight-square conical shapes, the taper ranges from 2.3 to 2.7, and the diameter of the center of the inner cavity is 43 cm; the structure is simple, disassembling is convenient, and the manufacturing cost is reduced.

Owner:JIANGSU TIANGONG TOOLS CO LTD

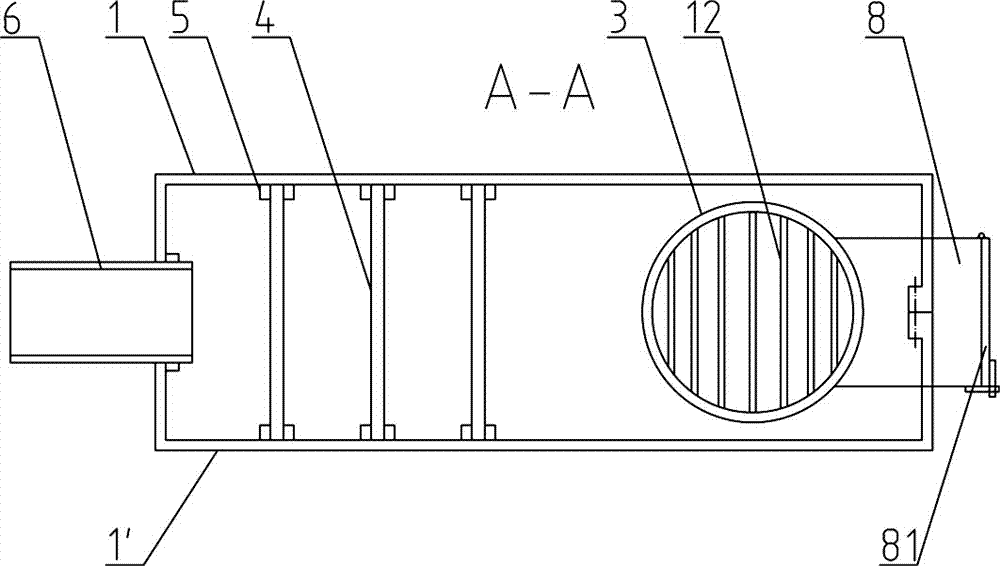

Integrated Pit Tunnel Boring Machine

ActiveCN105822316BMeet the rapid excavationExcavation is achieved quicklyTunnelsMotor driveWhole body

The invention discloses an integrated pit tunnel heading machine which comprises a rack and a drilling sawing mechanism, wherein the drilling sawing mechanism comprises arm levers, transmission shafts, driving motors, telescopic seats, drilling barrels, cutting wheels, a main motor, saw ropes and a plurality of guide wheels; the driving motors, the main motor, the telescopic seats and the plurality of guide wheels are all fixed on the rack; the arm levers are fixed on the telescopic seats; the transmission shafts are sleeved with the arm levers; the driving motors are connected with the transmission shafts in the arm levers; in the drilling process, the drilling barrels are fixed at the end parts of the transmission shafts, and the driving motors drive the drilling barrels to work by the transmission shafts; in the sawing process, the cutting wheels are movably arranged at the end parts of the arm levers, and the main motor drives the cutting wheels to work by the saw ropes and the plurality of guide wheels. The integrated pit tunnel heading machine disclosed by the invention solves the technical problems that a drilling mechanism and a sawing mechanism in an existing rope saw type heading machine are combined into one whole body; in the process of heading a pit tunnel, equipment does not need to enter and exit in a reciprocating manner; equipment calibration is reduced; heading of the pit tunnel can be rapidly implemented.

Owner:四川福隧科技有限公司

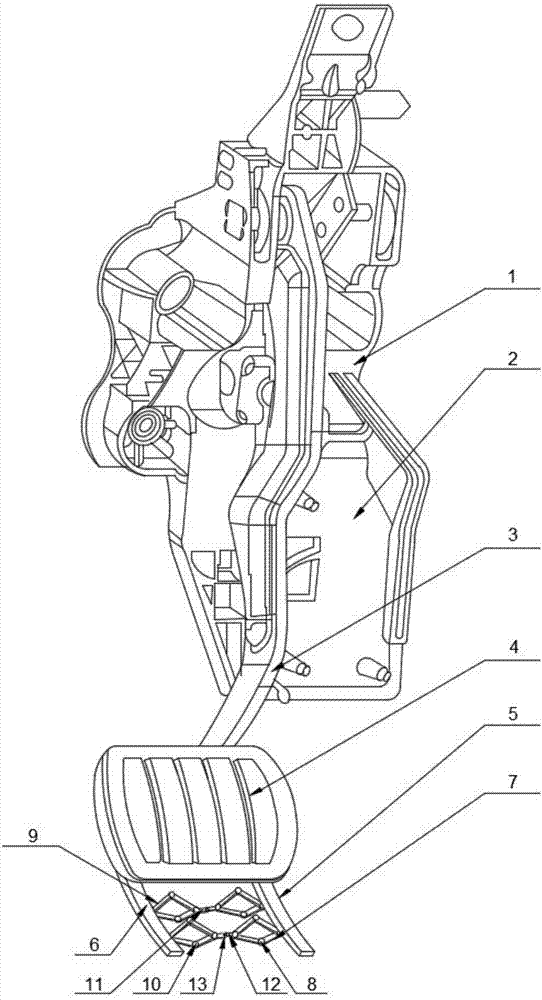

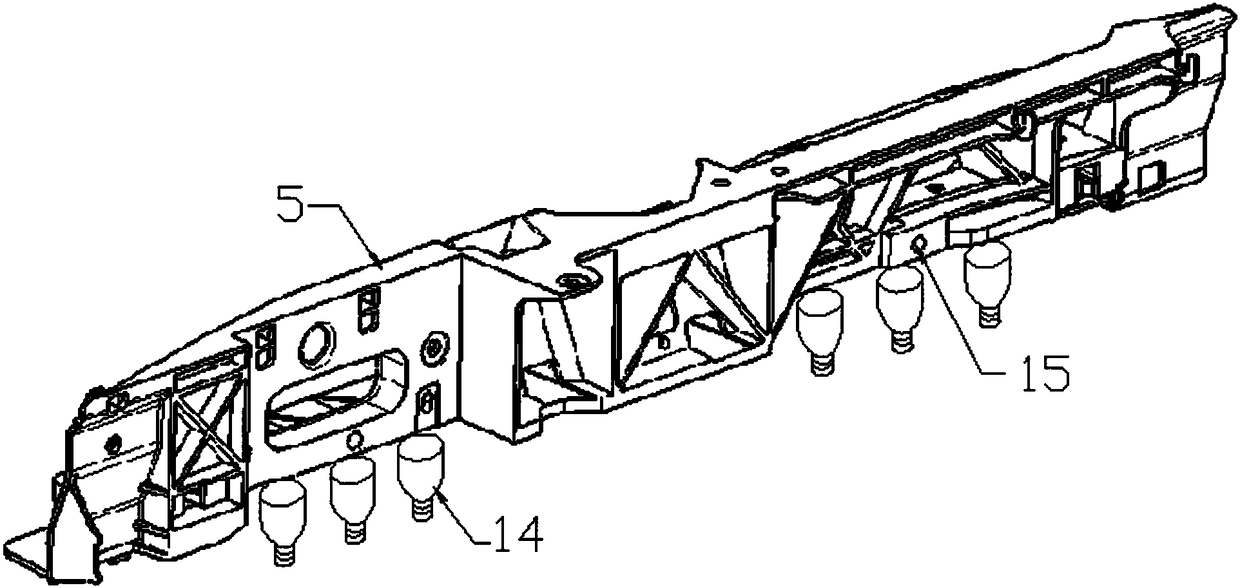

High-strength automobile brake pedal

InactiveCN107244313ASave materialLight in massFoot actuated initiationsHigh intensityUltimate tensile strength

The invention discloses a high-strength automobile brake pedal which comprises a brake pedal support. A brake pedal base is arranged at one end of the brake pedal support. The brake pedal support is rotationally connected with one end of a brake pedal arm, the other end of the brake pedal arm is fixedly connected with the brake pedal, the two ends of the bottom of the brake pedal are provided with a first lengthening arm and a second lengthening arm respectively, a first rhombus square rod is arranged on the first lengthening arm, a second rhombus square rod is arranged on the second lengthening arm, a first connecting rod is fixedly arranged at one end of the first rhombus square rod, a second connecting rod is fixedly arranged at one end of the second rhombus square rod, one end of the second connecting rod and one end of the first connecting rod are each provided with a screw hole, the brake pedal arm is of a unique reinforcing rib structure, few materials are adopted, the mass is lower, the cost is lower, the brake pedal can meet the target requirement for the strength performance, the safety of the whole automobile is improved, the lengthening structure is achieved, and shorter people can also use the brake pedal easily.

Owner:SHANDONG KINGOLD AUTOMOBILE CO LTD

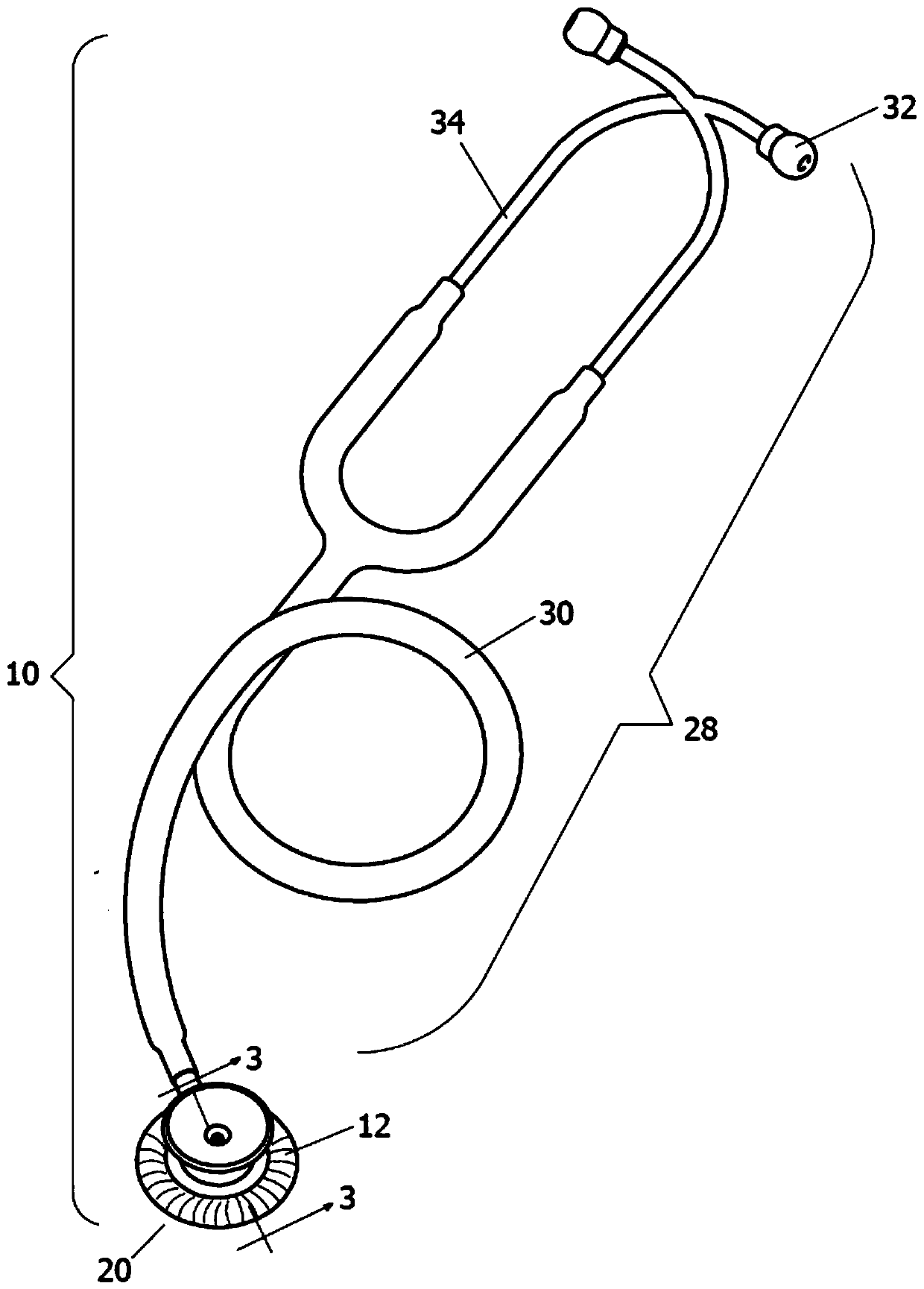

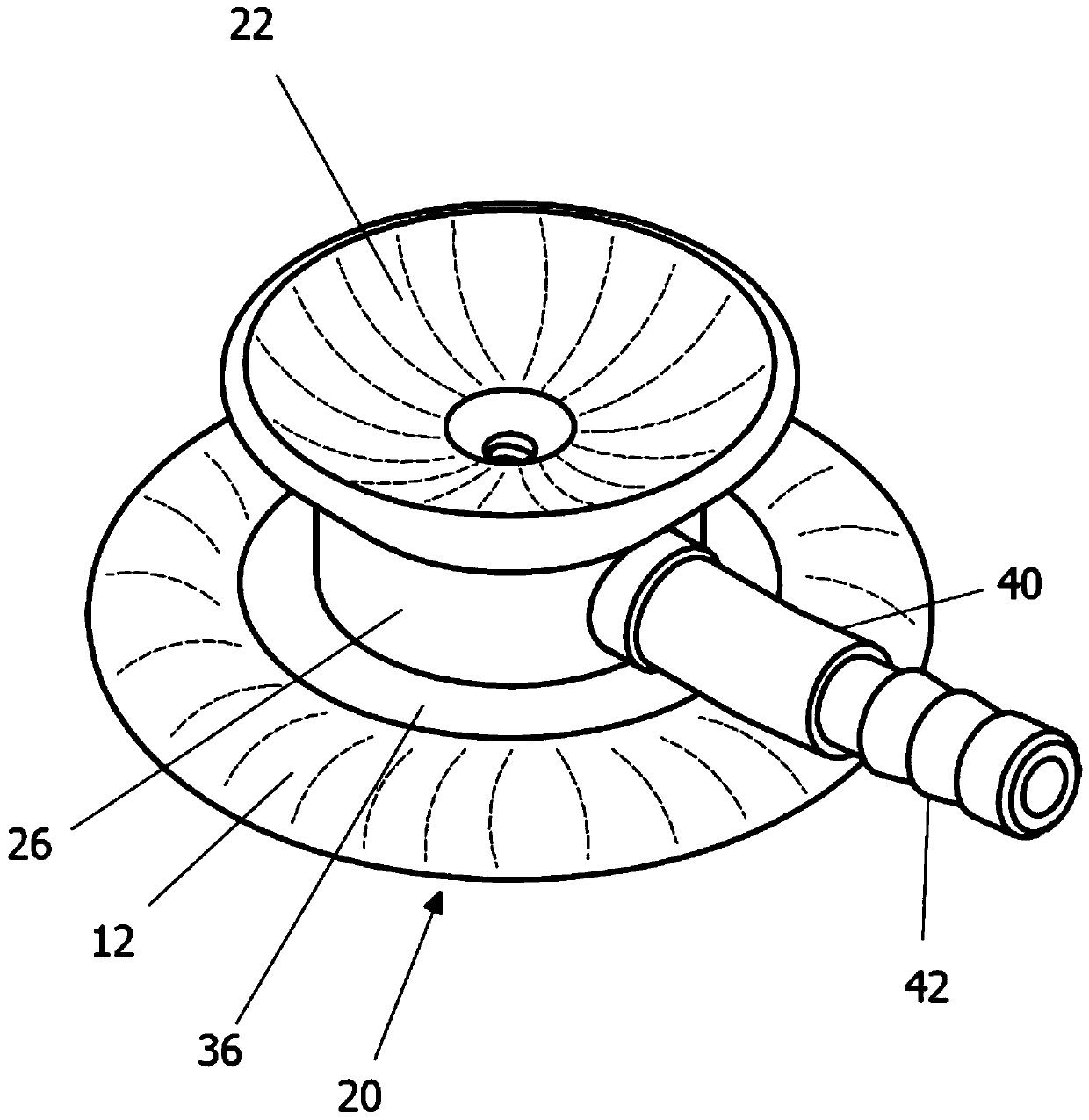

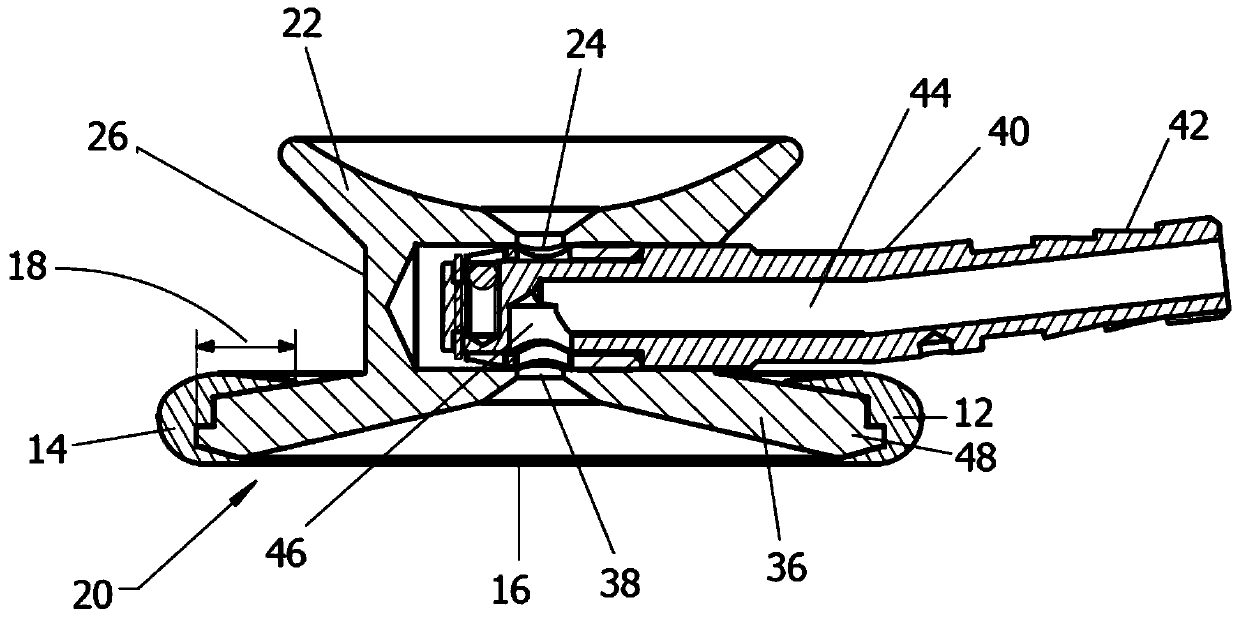

Integrated membrane sheet and ring and auscultation head

InactiveCN111035406AReduce audio attenuationComfortable touchStethoscopeMechanical engineeringVibrating membrane

The invention relates to an integrated membrane sheet and ring and an auscultation head. The auscultation head comprise two end surfaces of an auscultation head main body, wherein the two end surfacesare a bowl-shaped first surface and a second surface provided with a vibrating membrane, and are oppositely arranged in the opposite directions, the periphery of the second surface is provided with an edge, a one-sheet type membrane sheet and ring is assembled on the edge of the second surface of the auscultation head main body, the one-sheet type membrane sheet and ring comprises a membrane sheet part having a flat plate shape and an annular part connected to the periphery of the membrane sheet part, the annular part and the membrane sheet part are integrally formed, and the annular part isbuckled on the edge of the second surface of the auscultation head main body part. According to the invention, the auscultation head can reduce audio attenuation, is made of a non-toxic, odorless andflexible polymer material, and is easy to assemble, the hardness of the membrane ring material can be selected according to needs, the surface can also be machined, and the touch feeling is comfortable; the upper edge adopts wide edge design, tightly sleeves the main body, is not easy to separate, is attractive and elegant, and is convenient to use; and the machine is subjected to one-time formingso as to reduce the cost and improve the yield.

Owner:丁大伦

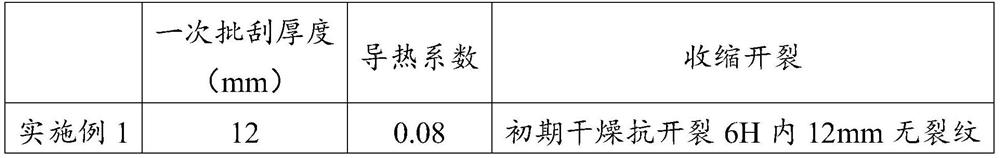

Deep groove stone-like paint putty powder

PendingCN114773895AImprove bindingAvoid problems such as shrinkage crackingFilling pastesShrinkage crackingPortland cement

The invention belongs to the technical field of building materials. The invention provides deep groove stone-like paint putty powder. The deep groove stone-like paint putty powder is prepared from, by mass, 25-35 parts of Portland cement, 45-55 parts of silica sand, 5-15 parts of mineral powder filler and 5-15 parts of reinforcing filler. According to the cement-based putty powder provided by the invention, the silica sand, the mineral powder filler and the reinforcing filler are added, so that the overall binding force of the putty powder is effectively improved, and all the components can be tightly combined together. The putty powder provided by the invention prominently solves the problem that the thickness of three times of batch scraping of a conventional product can be reached by one-time batch scraping, so that the construction difficulty is greatly reduced, and the construction is more efficient; the deep groove stone-like paint putty powder provided by the invention can be applied to a deep groove position, is easy to form in a batch scraping process, does not have the conditions of missing coating, sagging and the like, has good heat preservation and heat insulation effects on a wall body, can ensure the stability of indoor temperature, and meanwhile, avoids the problems of shrinkage cracking and the like caused by non-uniform overlapping thickness of the putty powder in a later period.

Owner:江西富兴节能建材有限公司

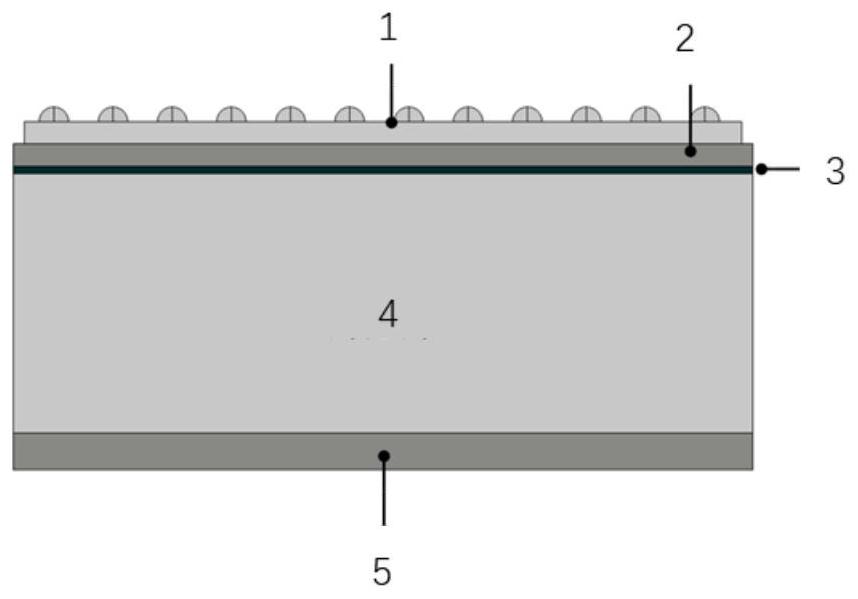

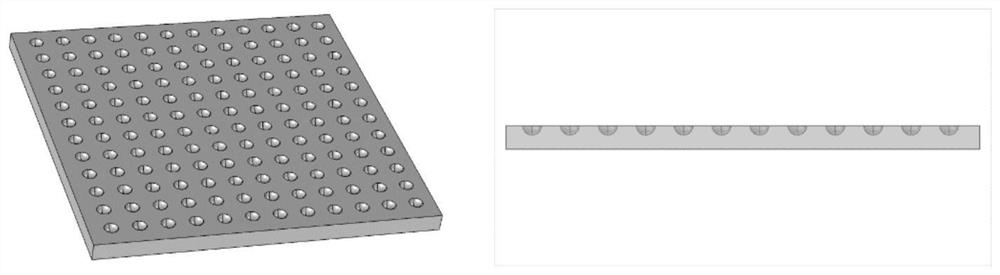

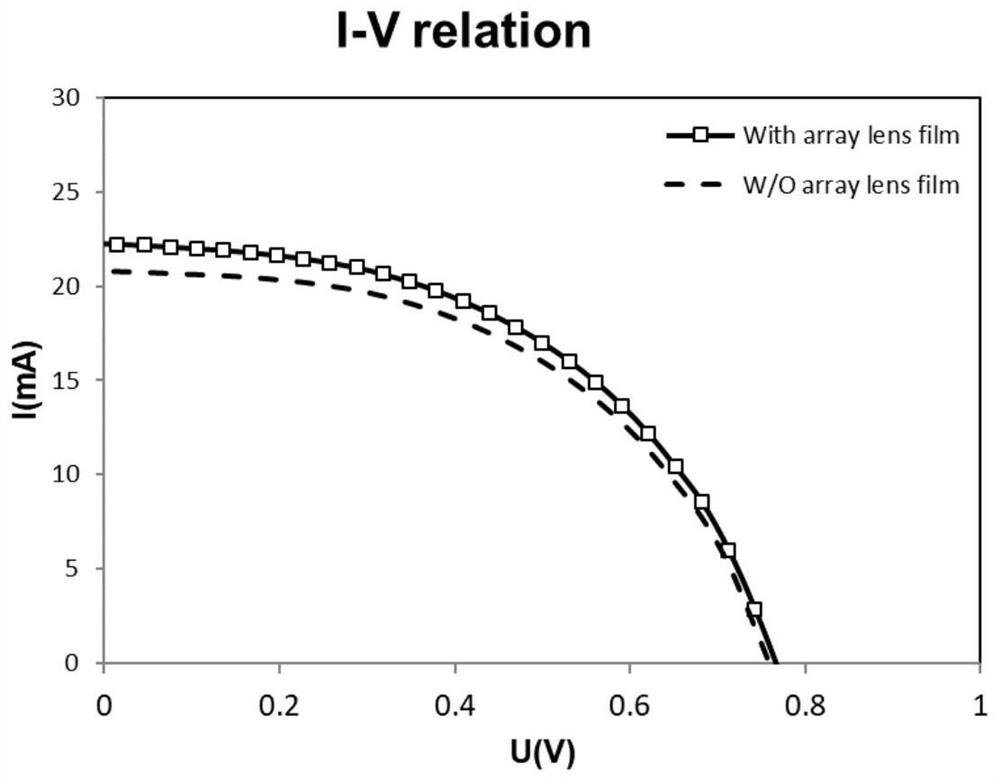

Graphene/gallium arsenide solar cell with array micro-nano lens structure and preparation method of graphene/gallium arsenide solar cell

PendingCN113690341AImprove light utilizationEnhanced light absorptionPhotomechanical apparatusNanotechnologyElectrical batteryGraphite

The invention discloses a graphene / gallium arsenide solar cell with an array micro-nano lens structure and a preparation method of the graphene / gallium arsenide solar cell. The graphene / gallium arsenide solar cell sequentially comprises a back electrode, a gallium arsenide layer, a graphene layer, a gate electrode and a thin film with a surface array micro-nano lens structure from bottom to top. The graphene / gallium arsenide solar cell prepared by the invention has the advantages of higher light utilization efficiency, enhanced light absorption on the surface of the cell, improved photoelectric conversion efficiency and the like, and the prepared thin film with the micro-lens structure can better collect incident light on the surface of the cell, so the photovoltaic effect of the solar cell is facilitated; and the preparation of the graphene / gallium arsenide solar cell with high conversion efficiency is facilitated.

Owner:SOUTH CHINA UNIV OF TECH

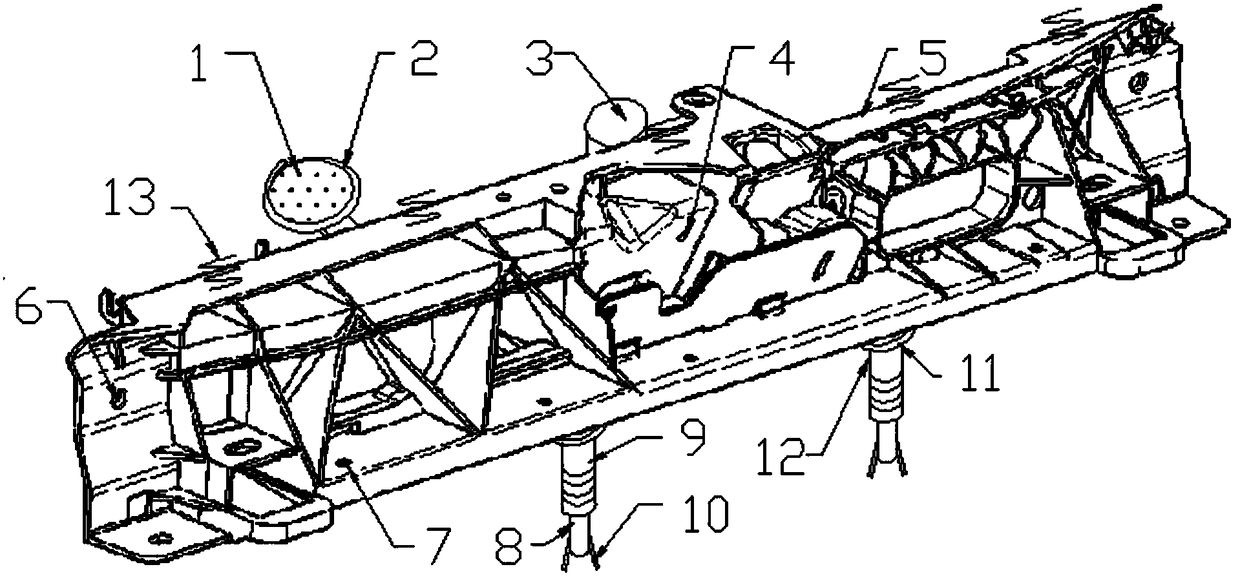

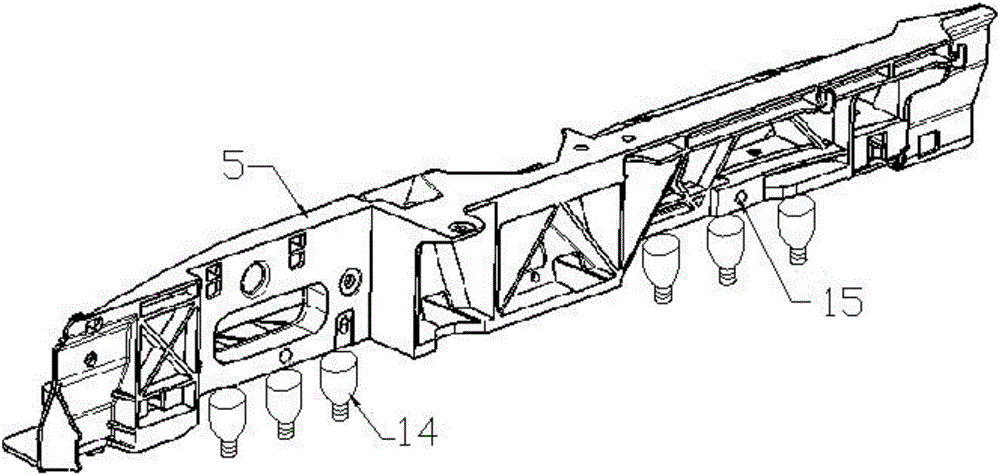

An upper beam of a passenger car water tank

InactiveCN106428221BImprove cooling effectGuaranteed StrengthSuperstructure subunitsPropulsion coolingEngineeringHeat spreader

Owner:国金汽车集团有限公司

Folding packaging and sealing equipment for clamshell packaging boxes

ActiveCN113276475BEasy to foldFold preciselyBox making operationsPaper-makingCardboardStructural engineering

The invention discloses a folding packaging and sealing device for a clamshell packaging box, which relates to the field of packaging boxes and includes a mechanism seat, a cutting mechanism, a folding mechanism, a packaging mechanism, and cardboard. The mechanism seat is a fixed platform for the entire device. The cardboard is placed on the top by means of a conveyor belt, and a cutting mechanism is set directly above the cardboard. The cutting mechanism cuts the cardboard into shape at one time through the cooperation of the cutting part and the inner body part. Mechanism, when the cardboard reaches the folding mechanism, the folding mechanism is responsible for folding the cardboard into the shape of the packaging box, and then pastes and seals the folded sides through the packaging mechanism.

Owner:南通市集业包装有限公司

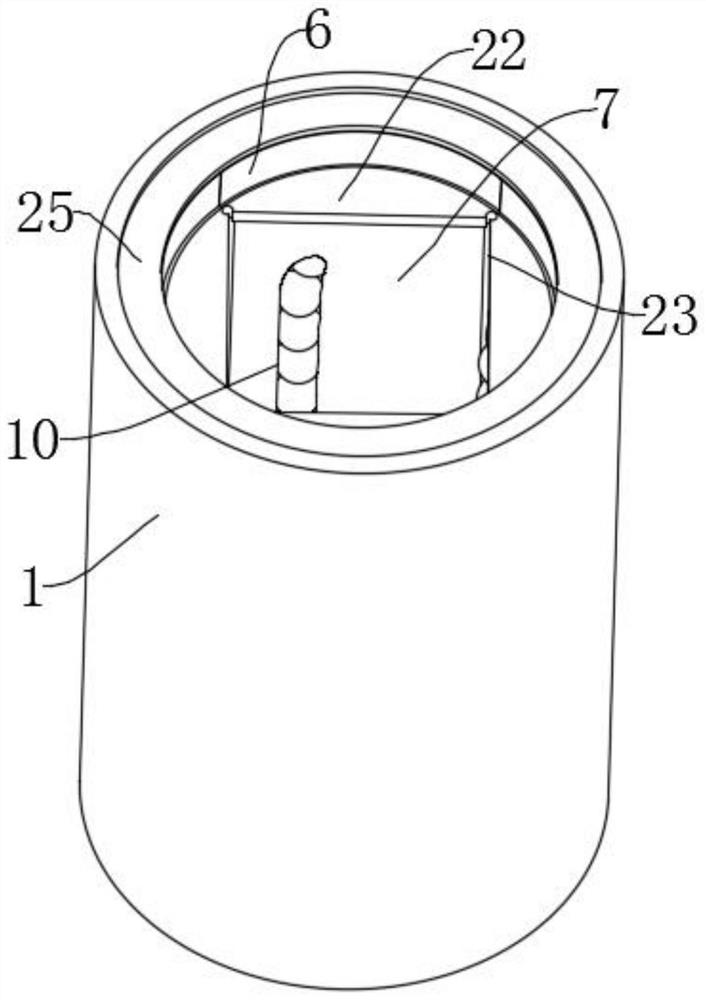

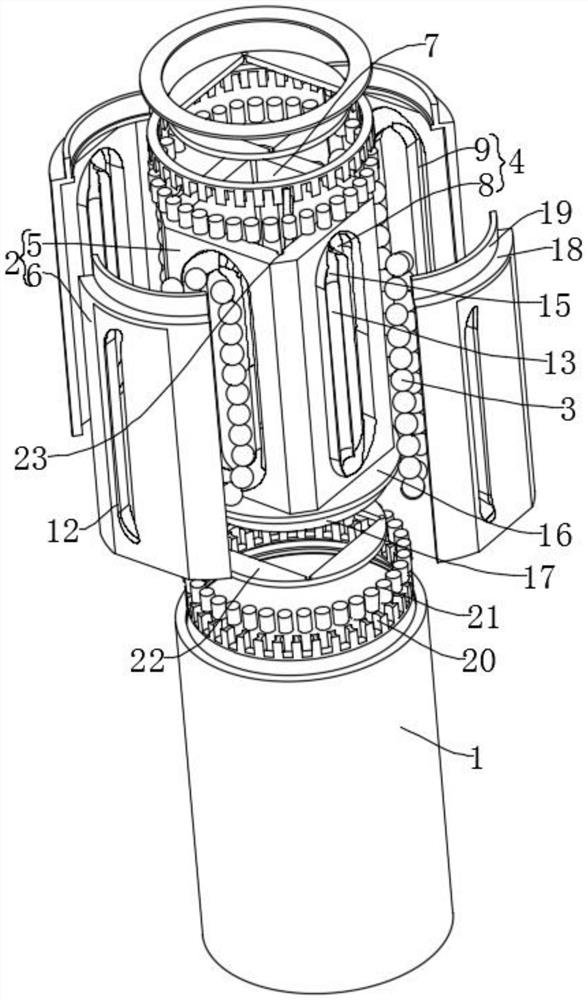

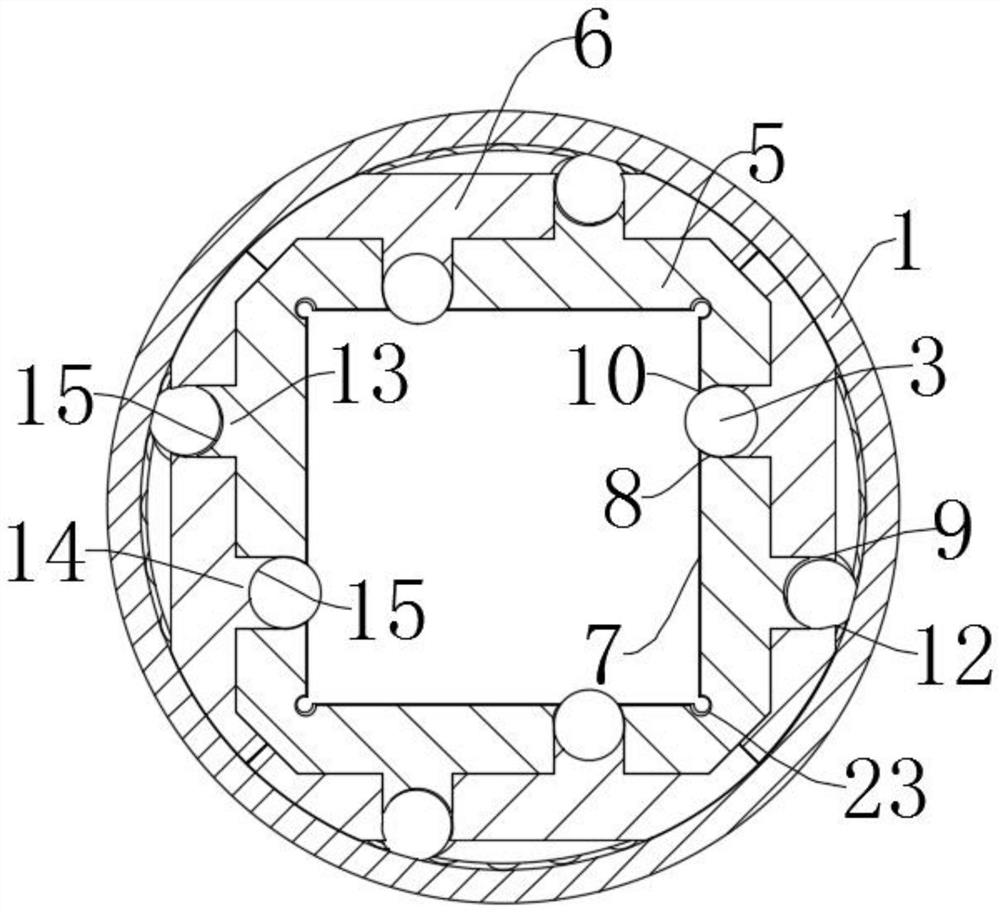

Linear bearing applicable to square tube

ActiveCN112431857AEasy to put inEasy to moveLinear bearingsBearing componentsStructural engineeringMechanical engineering

The invention relates to the field of bearings, and discloses a linear bearing applicable to a square tube. The linear bearing comprises a bearing outer sleeve, a first retainer and a plurality of first rolling bodies; the first retainer is provided with a plurality of spaced circulating roller paths; the first rolling bodies are connected in the circulating roller paths in a rolling manner; the first retainer comprises a first frame body and a second frame body arranged outside the first frame body in a sleeving manner; each circulating roller path comprises a first roller path body arrangedon the first frame body and a second roller path body arranged on the second frame body, a square sliding hole used for sleeving the square tube is formed in the first frame body in the axis direction, the first roller path body communicates with the sliding hole of the first frame body to form a first crack groove, the second roller path body communicates with the outer side of the second frame body to form a second crack groove, the first crack groove and the second crack groove are formed in the axis direction of the bearing outer sleeve, the widths of the first crack groove and the secondcrack groove are smaller than the diameter of each first rolling body, the first rolling body in the first crack groove abuts against the square tube, and the first rolling body in the second crack groove abuts against the inner wall of the bearing outer sleeve.

Owner:宁波美亚特精密传动部件有限公司

Carbon fiber microchip reactor

ActiveCN103551096BLight in massImprove corrosion resistanceChemical/physical/physico-chemical processesFiberElectricity

The invention discloses a carbon fiber microchip reactor. The carbon fiber microchip reactor has a multi-layer structure. From top to bottom, there are a first thermal or electrical conductive layer, an upper carbon fiber sealing plate, a carbon fiber reaction channel layer, and a lower carbon fiber sealing plate. and a second thermally conductive or electrically conductive layer; the carbon fiber reaction channel layer contains microchannels for fluids to carry out chemical reactions; the carbon fiber reaction channel layer, the upper carbon fiber sealing plate and the lower carbon fiber sealing plate are all made of carbon fiber plates. The invention also has the following advantages: 1. Light weight; 2. Extremely strong corrosion resistance, acid and alkali resistance; 3. Super thermal conductivity; 4. Easy to form at one time and mass production, which is in line with the development of future chemical processes. Trending equipment needs.

Owner:NANJING TECH UNIV

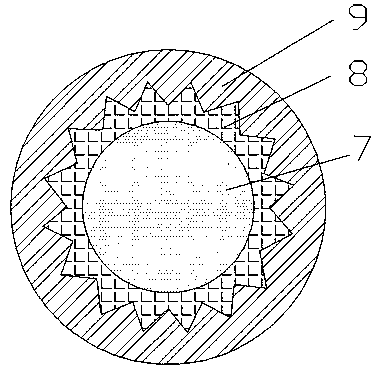

Powder alloy pressing mold used for output shaft

The invention discloses a powder alloy pressing mold used for an output shaft. The powder alloy pressing mold comprises an upper mold body and a lower mold body, and further comprises a middle mold body arranged between the upper mold body and the lower mold body. A mold cavity of the middle mold body is filled with metal powder used for molding the output shaft. The upper mold body comprises an upper guide sleeve and a pressing rod, wherein a square end opening is formed in one end of the upper guide sleeve, the pressing rod is matched with a square through hole axially formed in the axis of the upper guide sleeve, and one end of the upper guide sleeve is matched with the upper end of the mold cavity of the middle mold body; the lower mold body comprises a lower guide sleeve and an ejector rod, wherein four long grooves are axially and evenly formed in the circumferential wall of an end opening in one end of the lower guide sleeve, the ejector rod is matched with a circular hole axially formed in the axis of the lower guide sleeve, and one end of the lower guide sleeve is matched with the lower end of the mold cavity of the middle mold body. As the upper mold body is matched with the lower mold body, complex structures at the two ends of the output shaft can be conveniently molded, the secondary machining trouble is saved, the powder alloy pressing mold brings convenience to one-time molding of the output shaft, and the machining accuracy and the production efficiency are high.

Owner:TAICANG JINLIDE POWDER METALLURGY

Combustion furnace and furnace body structure

ActiveCN104896515AHigh forming precisionImprove installation efficiencyDomestic stoves or rangesLighting and heating apparatusCombustion chamberEngineering

Disclosed is a furnace body structure. The furnace body is divided into a plurality of portions through a vertical division structure; every two adjacent portions are connected through a connecting part; the furnace body is provided with a chimney opening, a fire outlet, a feeding inlet and an ash hopper or an air inlet; the inner wall of the furnace body is provided with a separation plate which is formed in a one-step mode and is roughly horizontal or the inner wall of the furnace body is provided with a supporting block which is used for supporting the separation plate which is roughly horizontal. The invention also provides a combustion furnace with the furnace body structure. The separation plate is arranged in the furnace body; the lower portion space of the furnace body is isolated into an ash chamber through the separation plate; a combustion chamber is located above the separation plate which is arranged in the furnace body; an inner chamber of the combustion chamber is communicated with the ash chamber; a channel for the flus gas to pass through is formed between the top of the combustion chamber and the inner side of the top of the furnace body; the furnace body is provided with a feeding channel and a chimney connection pipe. According to the combustion furnace and the furnace body structure, the vertical division structure is adopted and accordingly the stripping of every structural portion in the furnace body is facilitated, the one-step forming through a die is facilitated, the forming accuracy is high, and the installation efficiency of the integral combustion furnace is greatly improved.

Owner:宜昌市永山创新科技有限责任公司

Folding packaging and sealing equipment for flip type packaging box

ActiveCN113276475AEasy to foldFold preciselyPaper-makingBox making operationsStructural engineeringManufacturing engineering

The invention discloses folding packaging and sealing equipment for a flip type packaging box, and relates to the field of packaging boxes. The folding packaging and sealing equipment comprises a mechanism seat, a cutting mechanism, a folding mechanism, a packaging mechanism and a paperboard. The mechanism seat is a fixing platform of the whole equipment, the paperboard is placed on the mechanism seat through a conveyor belt, and the cutting mechanism is arranged right above the paperboard. The cutting mechanism is used for cutting and forming the paperboard at a time through cooperation of a cutting piece and an inner body piece, the folding mechanism is arranged below the cutting mechanism, when the paperboard reaches the folding mechanism, the folding mechanism is responsible for folding the paperboard into the shape of a packaging box, and then the packaging mechanism is used for conducting pasting and packaging operation on several folded faces.

Owner:南通市集业包装有限公司

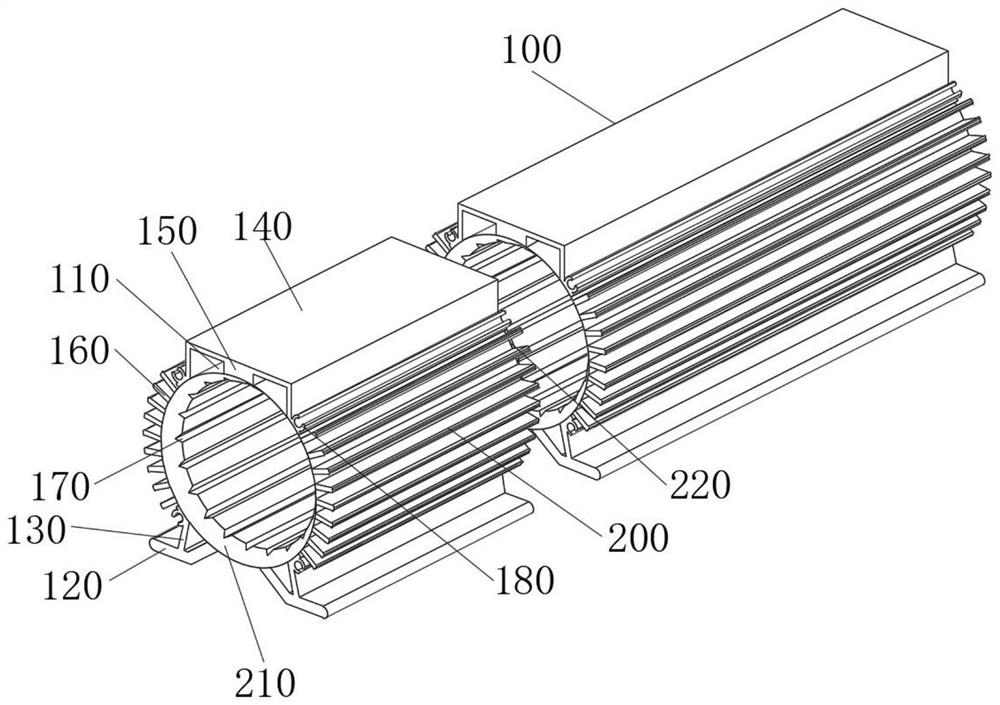

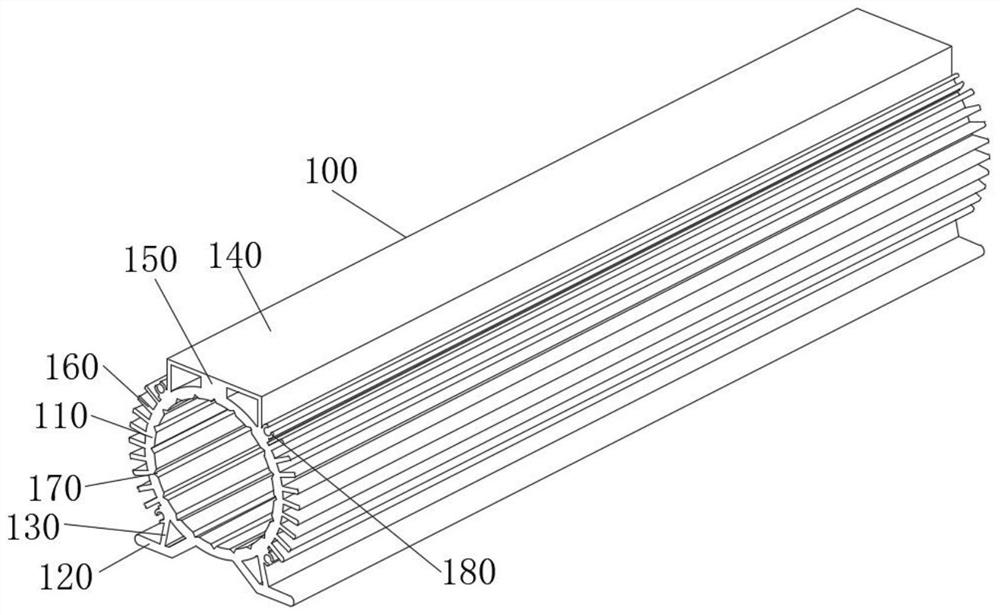

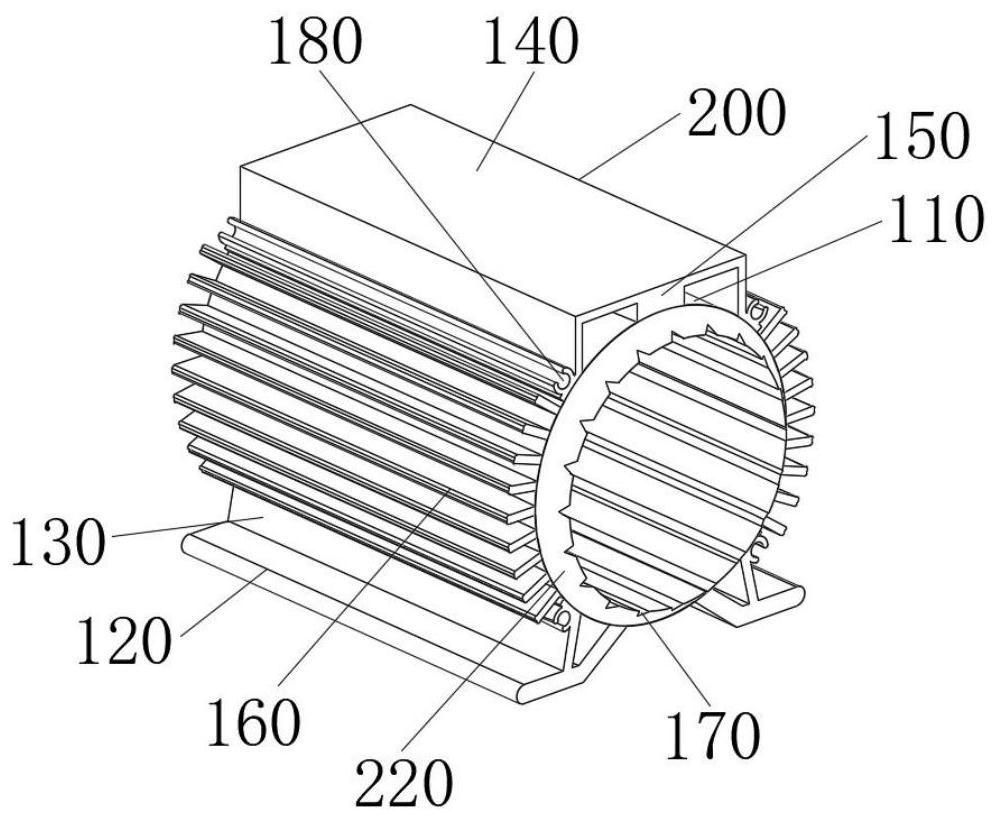

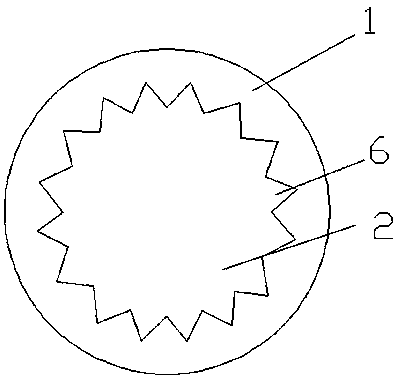

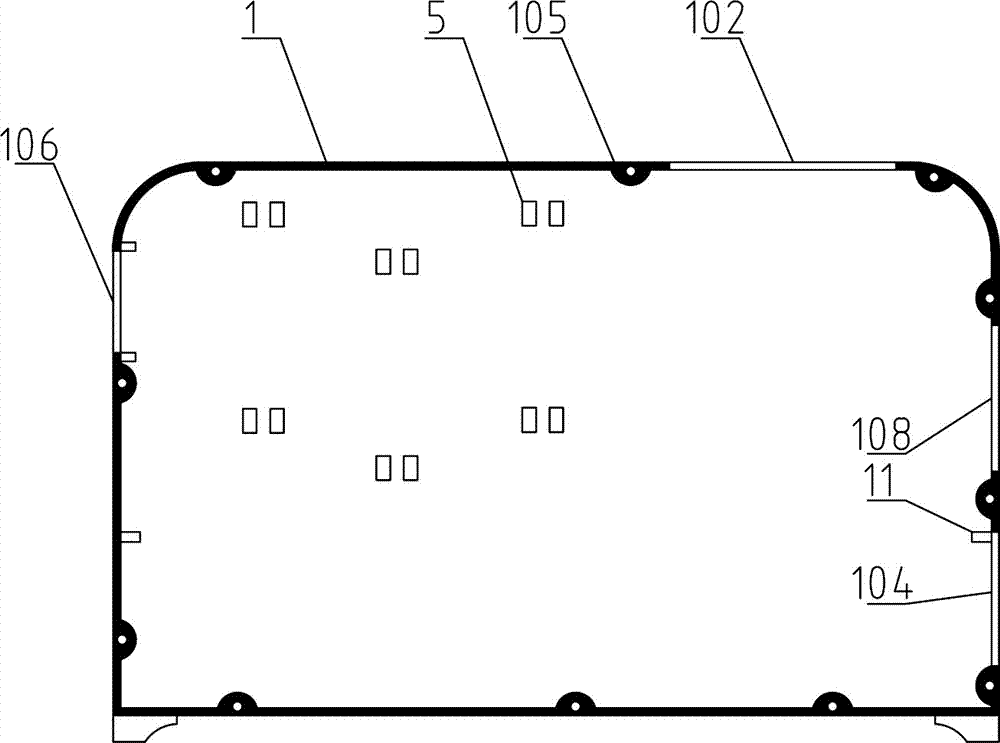

A motor housing based on one-time forming technology of aluminum profiles

ActiveCN111969758BEasy to mold at one timeReduce manufacturing costSupports/enclosures/casingsElectric machineHeat sink

The invention relates to the technical field of aluminum profile manufacturing equipment for motor casings, in particular to a motor casing based on the aluminum profile one-time molding technology, which includes an aluminum profile body, the aluminum profile body includes a cylinder, and the bottom of the cylinder is symmetrically fixed There are support legs, and a support plate is fixedly connected between the support leg and the cylinder body, a bearing platform is fixedly arranged on the top of the cylinder body, and a support pile is fixedly connected between the bearing platform and the cylinder body, the left and right sides of the cylinder body Radiating fins are evenly and equidistantly fixed on the outer walls of both sides. In the present invention, the projection path of the support legs, support plates, bearing platforms, support piles, heat sinks, grooves and hollow sleeves is set parallel to the central axis of the cylinder, so that the main body of the aluminum profile can be produced by die-casting Linear extrusion molding is performed, and at the same time, through two circular cuts, the aluminum profile main body is separated into an independent motor housing main body, which further reduces the production cost of the motor housing main body.

Owner:贵州锦兴轻合金装备制造有限公司

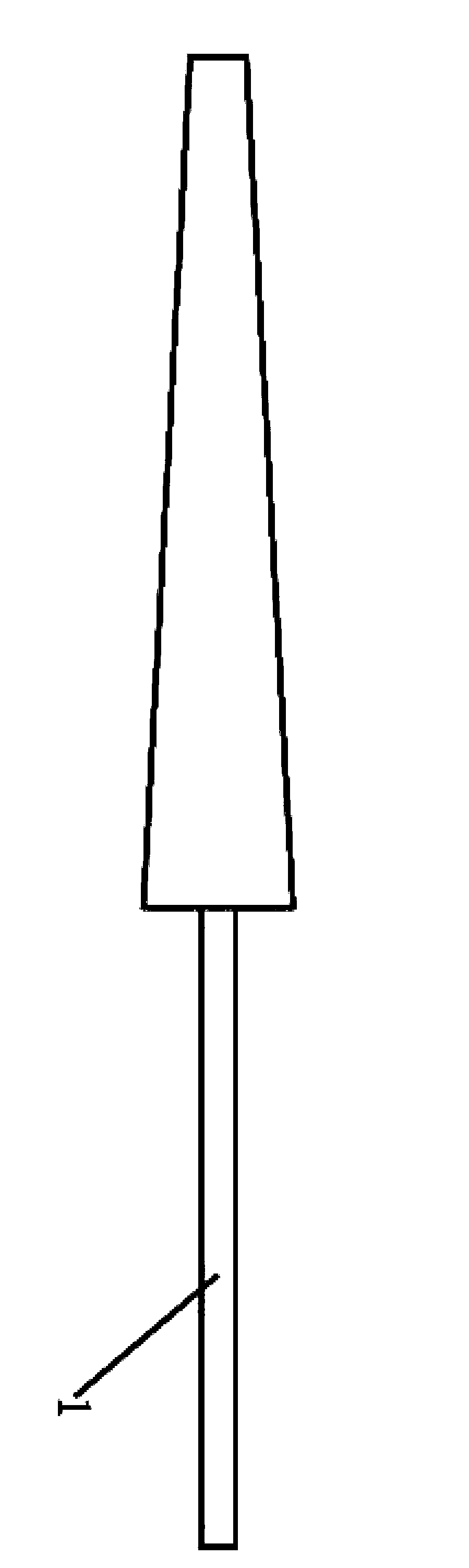

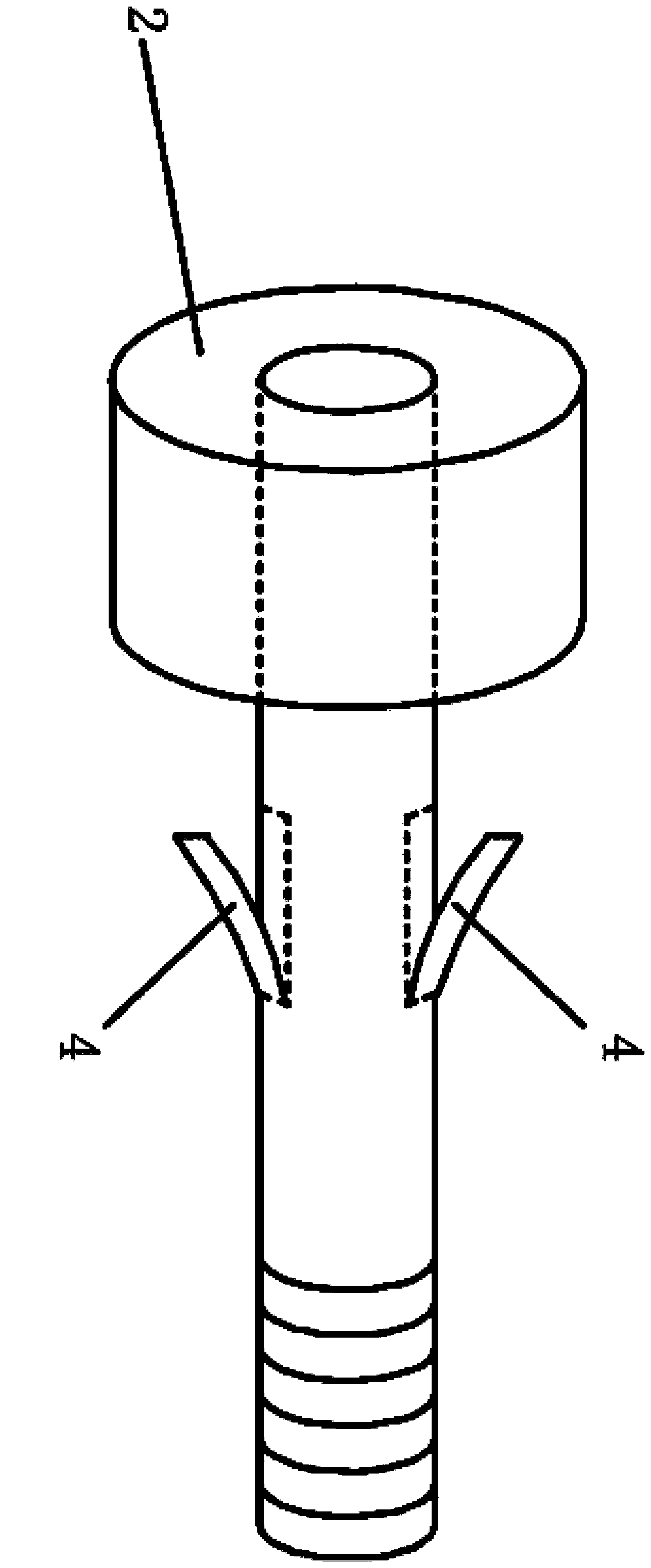

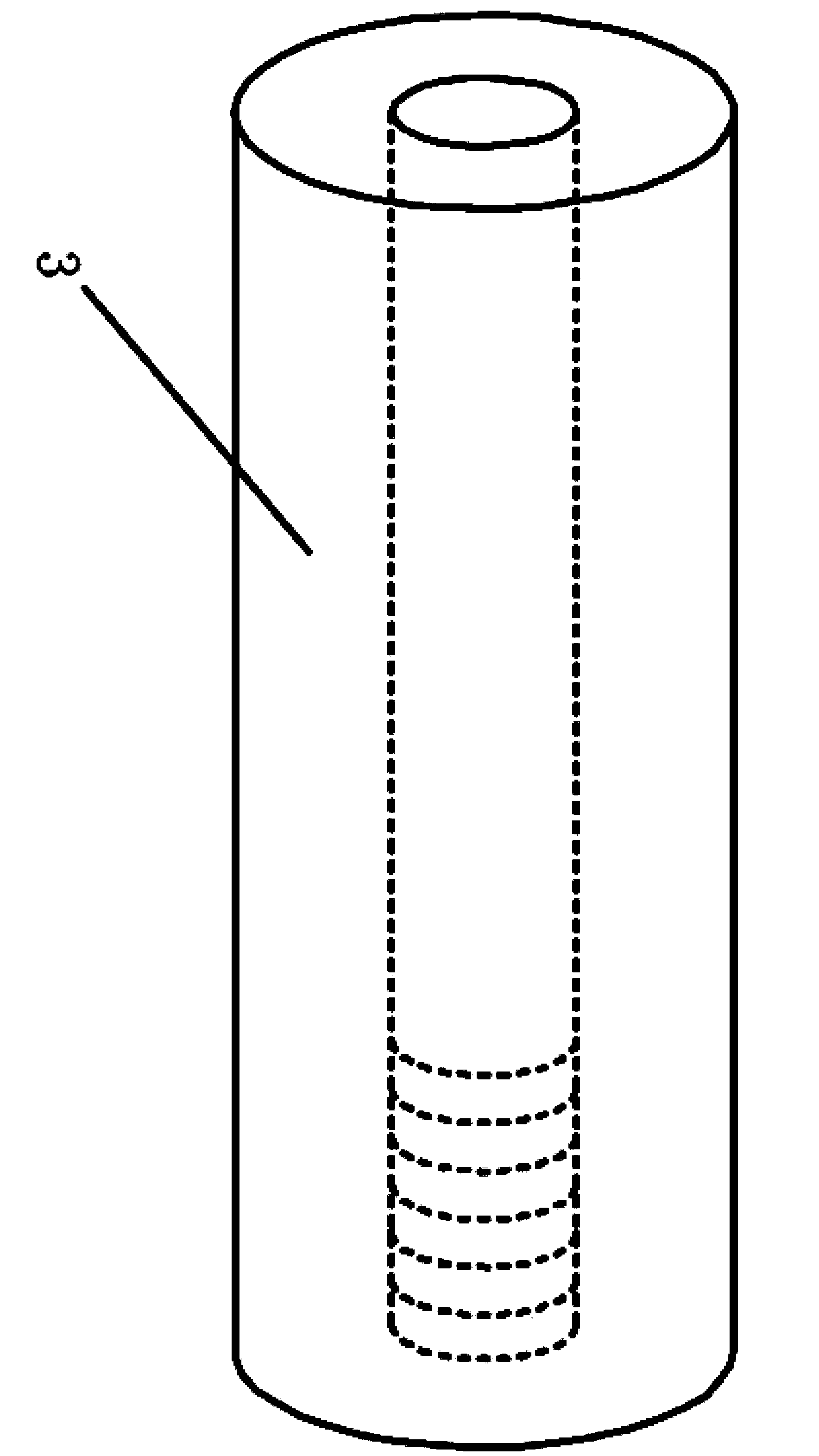

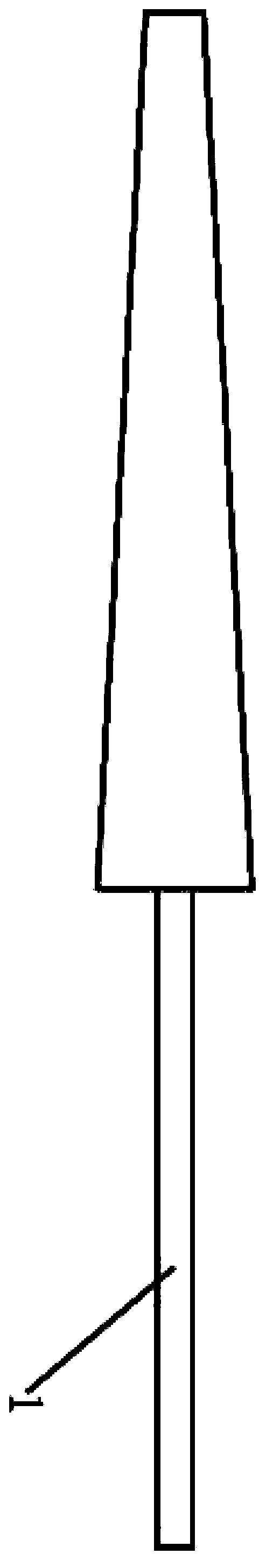

Connecting method of cue

The invention discloses a connecting method of a cue. According to the connecting method of the cue, a connecting rod (1), an inner cylinder (2) and an outer cylinder (3) are used, wherein the connecting rod (1) is connected to the tail end of a front cue branch and is a cylinder with a smooth surface, the connecting rod (1) is provided with no threads, a rear cue branch is formed by the inner cylinder (2) and the outer cylinder (3), the inner cylinder (2) and the outer cylinder (3) are connected through threads, the outer diameter of the front section of the inner cylinder (2) is identical with that of the outer cylinder (3), the inner diameter (2) of the inner cylinder (2) is identical with the outer diameter of the connecting rod (1), the outer diameter of the rear end of the inner cylinder (2) is identical with the inner diameter of the outer cylinder (3), two or more hollow grooves are formed at positions, close to the front section, of the rear end of the inner cylinder (2), the lower end of each hollow groove is connected with an elastic piece (4), the elastic pieces (4) tilt outwards under the condition that the elastic pieces (4) are not squeezed by external force, the elastic pieces (4) are withdrawn towards the hollow grooves when the elastic pieces (4) are pushed upwards in a rotary mode through threads together with the outer cylinder (3) and come close to the front end of the inner cylinder (3), and then the connecting rod (1) stretching into the inner cylinder (2) is clamped. The connecting method of the cue has the advantages that the length of the cue can be adjusted directly, and connection of the cue is firm.

Owner:饶涛

Combustion furnace and furnace body structure

ActiveCN107327873AImprove installation efficiencyImprove heat transfer efficiencyDomestic stoves or rangesLighting and heating apparatusCombustionHearth

The invention provides a furnace body structure. A furnace body is of a vertical subdivision structure and is divided into a plurality of parts, and all the parts are connected through connecting pieces. The furnace body is provided with a chimney port, a fire outlet, a feeding port and an ash hopper or an air inlet. The inner wall of the furnace body is provided with a roughly-horizontal partition plate formed at a time, or the inner wall of the furnace body is provided with a supporting block for supporting the roughly-horizontal partition plate. According to a combustion furnace adopting the furnace body structure, the partition plate is arranged in the furnace body and isolates the space of the lower portion of the furnace body into an ash cavity, a hearth is located above the partition plate in the furnace body, and an inner cavity of the hearth communicates with the ash cavity. A passageway for allowing smoke gas to pass through is formed between the top of the hearth and the inner side of the top of the furnace body, and the furnace body is provided with a feeding passageway and a chimney connecting pipe. According to the combustion furnace and the furnace body structure, by adoption of the vertical subdivision structure, mold release of all the structure parts in the furnace body is facilitated, one-time forming through molds is facilitated, the forming accuracy is high, and the mounting efficiency of the whole combustion furnace is greatly improved.

Owner:SHENGHUO (HUBEI) AGRI TECH CO LTD

Connecting method of cue

The invention discloses a connecting method of a cue. According to the connecting method of the cue, a connecting rod (1) which is connected to the tail end of a front cue branch is used, the connecting rod (1) is a cylinder with a smooth surface and is provided with no threads, one or more threaded through holes (2) are formed in the front end of a rear cue branch, the diameter of the outer side of each through hole (2) is larger than the diameter of the inner side of the through hole (2), the through holes (2) are matched with screws (3), when the screws (3) are rotated to stretch into the through holes (2) and are tightened, the connecting rod (1) stretching into the rear cue branch is clamped by the screws (3), and screw heads of the screws (3) are hidden in the outer wall of the rear cue branch instead of being convex on the outer wall of the rear cue branch. The connecting method of the cue has the advantages that the length of the cue can be adjusted directly, and connection of the cue is firm.

Owner:饶涛

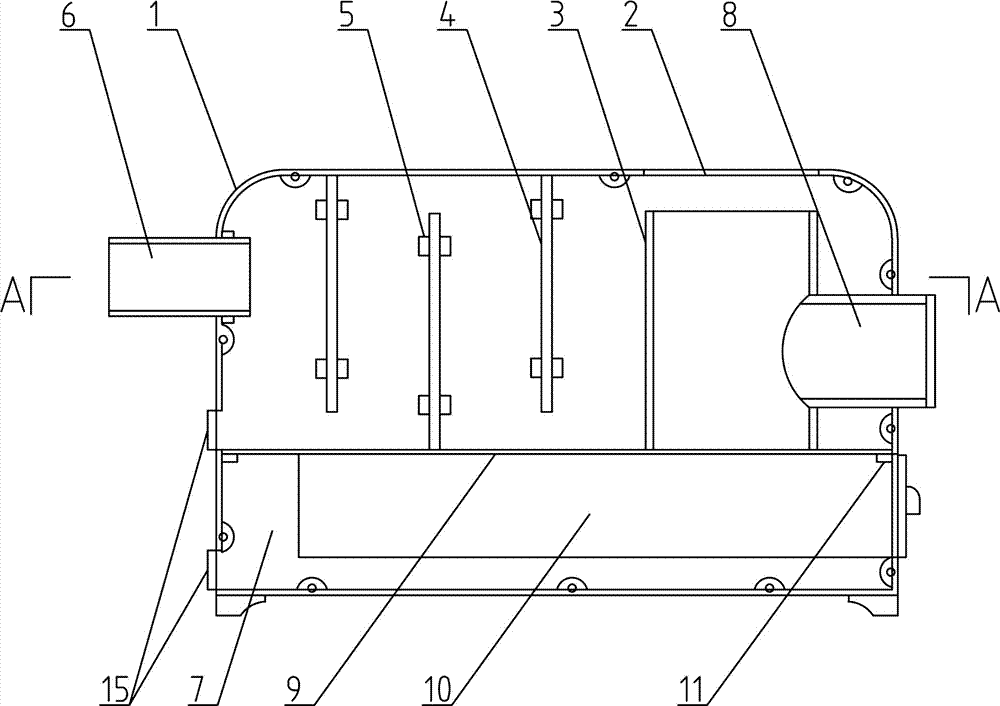

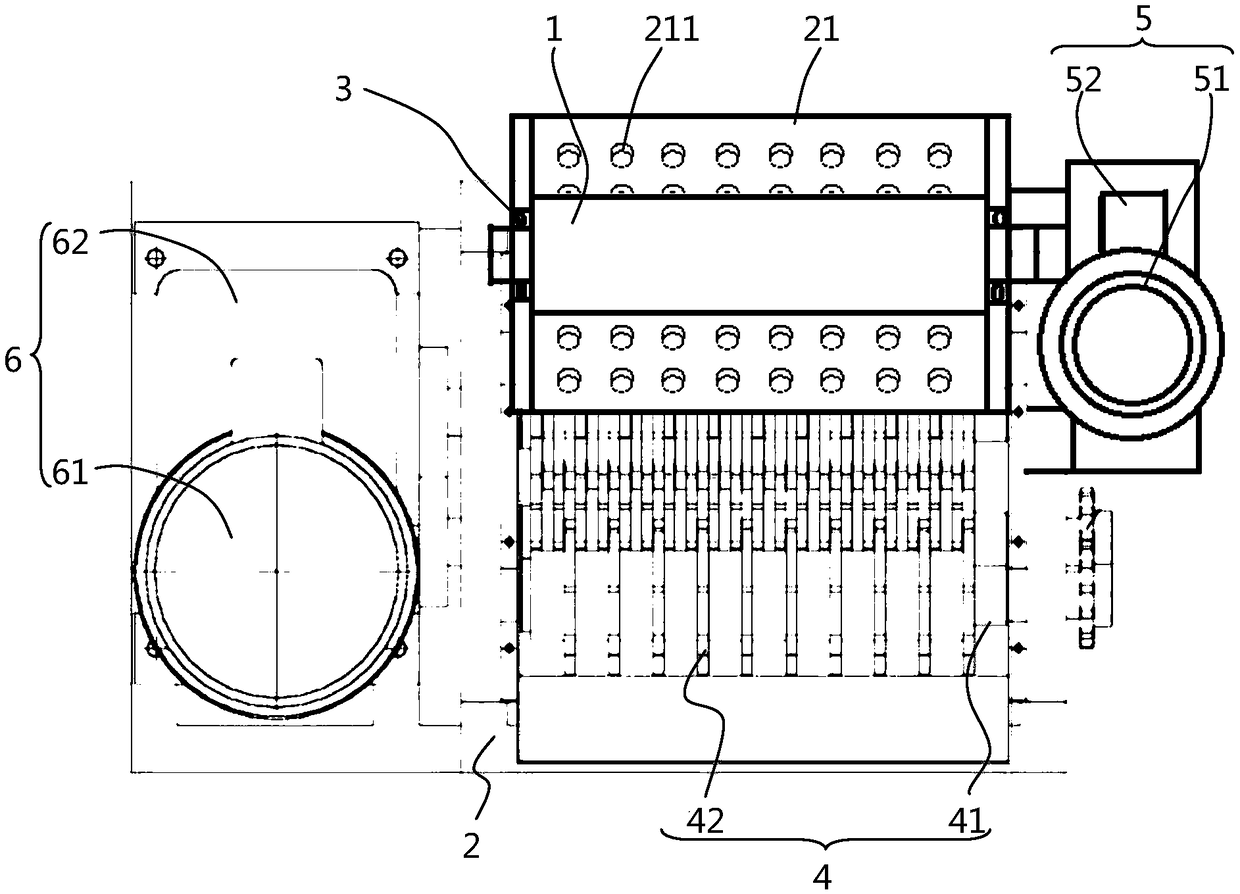

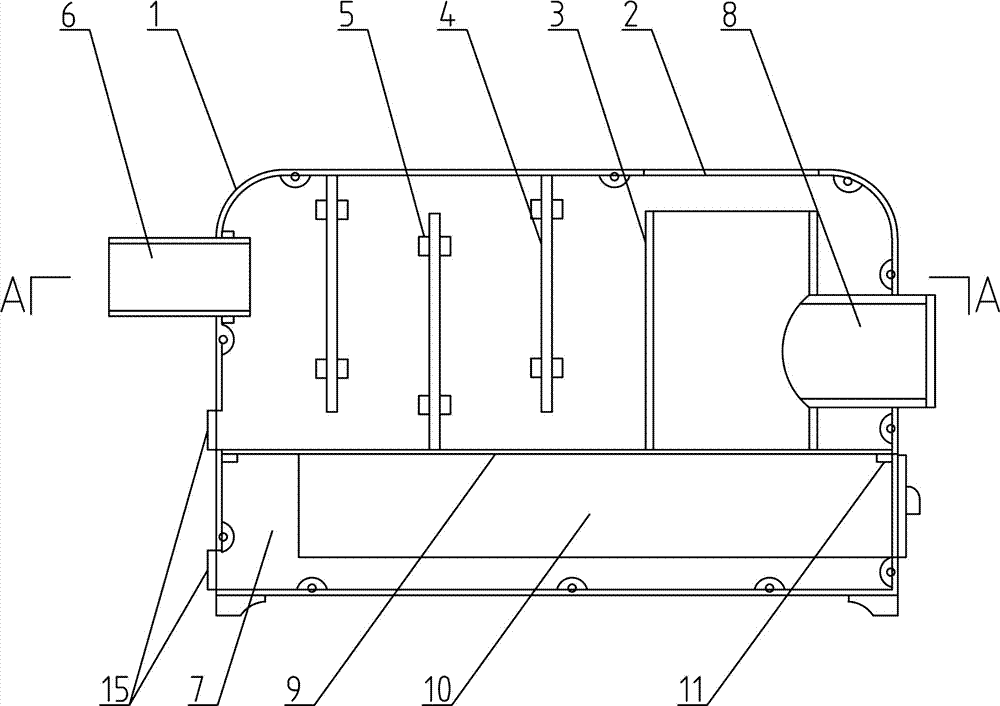

Combined double-shaft shredding machine and working method thereof

InactiveCN109046661AExtended service lifeMeet the requirements of output sizeGrain treatmentsCrusherElectrical and Electronics engineering

The invention discloses a combined double-shaft shredding machine and a working method thereof and belongs to the technical field of shredding machines. The combined double-shaft shredding machine comprises crushing rolls, a case, a shredding tool, a first power system and a second power system. The first power system and the second power system are installed on the case, an inclined rolling platform is arranged on the upper feeding portion of the case, the crushing rolls are fixed to two sides of the rolling platform through bearings and connected with the first power system, and the effective distances from the crushing rolls to the rolling platform are 10-15 mm. The shredding tool is arranged in the case, the second power system is connected with the shredding tool, and a discharging port of the rolling platform is located above the shredding tool. Due to the fact that the crushing rolls are installed on the double-shaft shredding case, kitchen waste is evenly fed to the crushing rolls through a conveyor, hard bones are crushed, then the kitchen waste is fed to the double-shaft shredding machine to be smashed, the discharging size of the shredding machine can be controlled within the range from 3 mm to 5 mm in this way, and thus the discharging size requirements of customers are met.

Owner:马鞍山恒隆机械科技有限公司

Passenger car water tank upper beam

ActiveCN106428221AImprove cooling effectGuaranteed StrengthSuperstructure subunitsPropulsion coolingEngineeringHeat spreader

Owner:国金汽车集团有限公司

Rubber roller forming mold and processing method thereof

InactiveCN111136877AEasy to mold at one timeHigh precisionTubular articlesEngineeringMechanical engineering

The invention provides a rubber roller forming mold and a processing method thereof. The mold includes a mold body, and a cavity is formed in the mold body. The cavity includes a first cavity body anda second cavity body communicating with each other. The inner diameter of the first cavity body is smaller than the inner diameter of the second cavity body, the inner wall of the first cavity body is a curved surface, and the mold body is provided with a feeding port. According to the scheme, the forming of rubber rollers at one time is facilitated, the subsequent processes of rubber roller production and processing are reduced, the processing efficiency and the processing quality of the rubber rollers are effectively improved, the structural strength of the rubber rollers is effectively improved, the risk of degumming is reduced, the connection strength between a hard rubber layer and a soft rubber layer is improved, the glossiness of the surfaces and the concentricity of the rubber rollers are improved, and the service life of the rubber rollers is effectively prolonged.

Owner:益阳市思创传动部件制造有限公司

Combustion furnace and furnace body structure

ActiveCN104896515BImprove installation efficiencyImprove heat transfer efficiencyDomestic stoves or rangesLighting and heating apparatusCombustion chamberEngineering

Disclosed is a furnace body structure. The furnace body is divided into a plurality of portions through a vertical division structure; every two adjacent portions are connected through a connecting part; the furnace body is provided with a chimney opening, a fire outlet, a feeding inlet and an ash hopper or an air inlet; the inner wall of the furnace body is provided with a separation plate which is formed in a one-step mode and is roughly horizontal or the inner wall of the furnace body is provided with a supporting block which is used for supporting the separation plate which is roughly horizontal. The invention also provides a combustion furnace with the furnace body structure. The separation plate is arranged in the furnace body; the lower portion space of the furnace body is isolated into an ash chamber through the separation plate; a combustion chamber is located above the separation plate which is arranged in the furnace body; an inner chamber of the combustion chamber is communicated with the ash chamber; a channel for the flus gas to pass through is formed between the top of the combustion chamber and the inner side of the top of the furnace body; the furnace body is provided with a feeding channel and a chimney connection pipe. According to the combustion furnace and the furnace body structure, the vertical division structure is adopted and accordingly the stripping of every structural portion in the furnace body is facilitated, the one-step forming through a die is facilitated, the forming accuracy is high, and the installation efficiency of the integral combustion furnace is greatly improved.

Owner:盛火电商宜昌有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com