Rubber roller forming mold and processing method thereof

A technology for forming molds and rubber rollers, which is used in household appliances, other household appliances, applications, etc., can solve the problems affecting the processing efficiency of rubber rollers, the glossiness or smoothness cannot meet the requirements for use, and the quality of products. Risk of degumming, improving production and processing efficiency, and reducing the effect of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

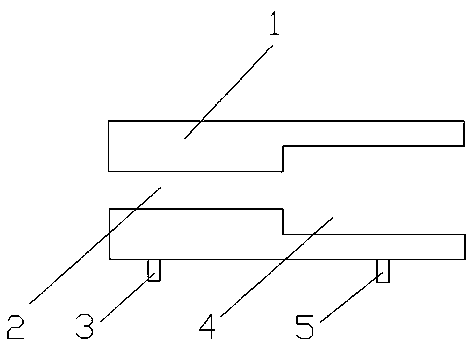

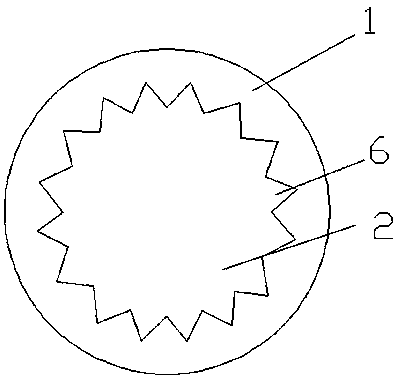

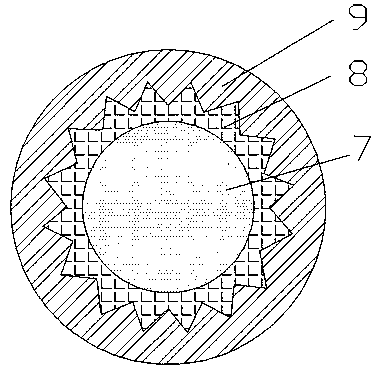

[0031] As shown in the accompanying drawings: a rubber roller forming mold, including a mold body 1, a cavity is provided in the mold body 1, and the cavity includes a first cavity 2 and a second cavity 4 that communicate with each other, and the first cavity 2 The inner diameter is smaller than the inner diameter of the second cavity 4 , the inner wall of the first cavity 2 is a curved surface, and the mold body 1 is provided with a feeding port 10 .

[0032] The feeding port 10 includes a hard rubber feeding port 3 arranged on the first cavity 2 and a soft rubber feeding port 5 on the second cavity 4 . It facilitates one-time forming of the rubber roller 13, prevents long-distance operation, contaminates the hard rubber surface with impurities, affects the combination between the hard rubber layer 8 and the soft rubber layer 9, affects the structural strength of the rubber roller 13, and facilitates the improvement of processing efficiency. A runner 12 is arranged outside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com