Combustion furnace and furnace body structure

A furnace body structure and furnace body technology, which is applied in the direction of household stoves/stoves, solid heating fuel, lighting and heating equipment, etc., can solve the problems of increasing wind resistance, poor thermal conductivity of the furnace body, and affecting combustion efficiency, so as to improve installation efficiency, High molding precision and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

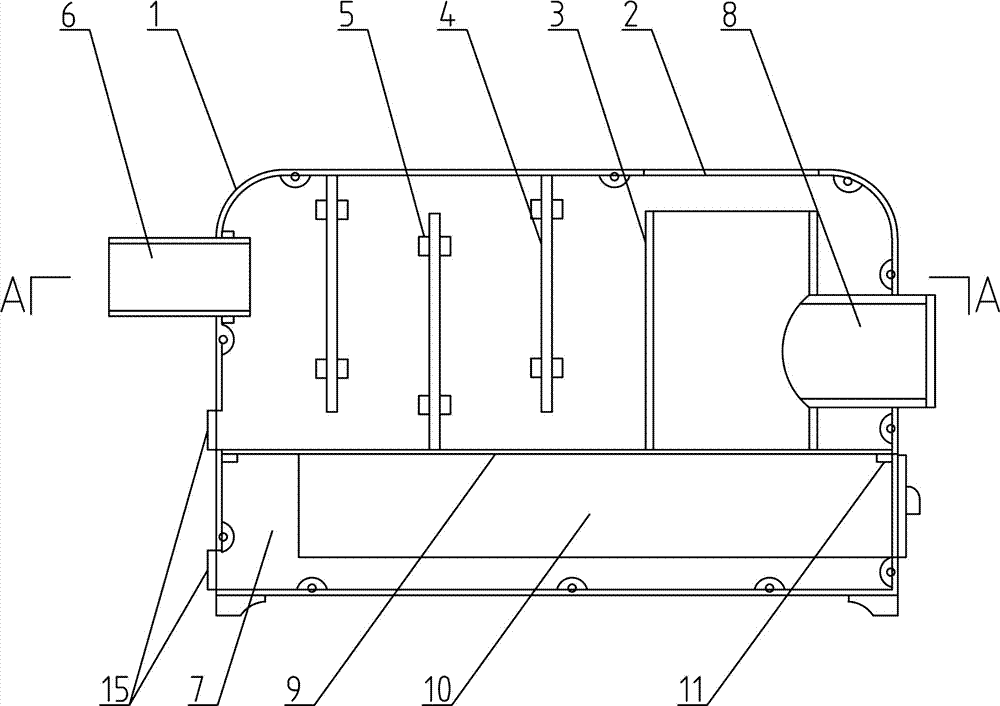

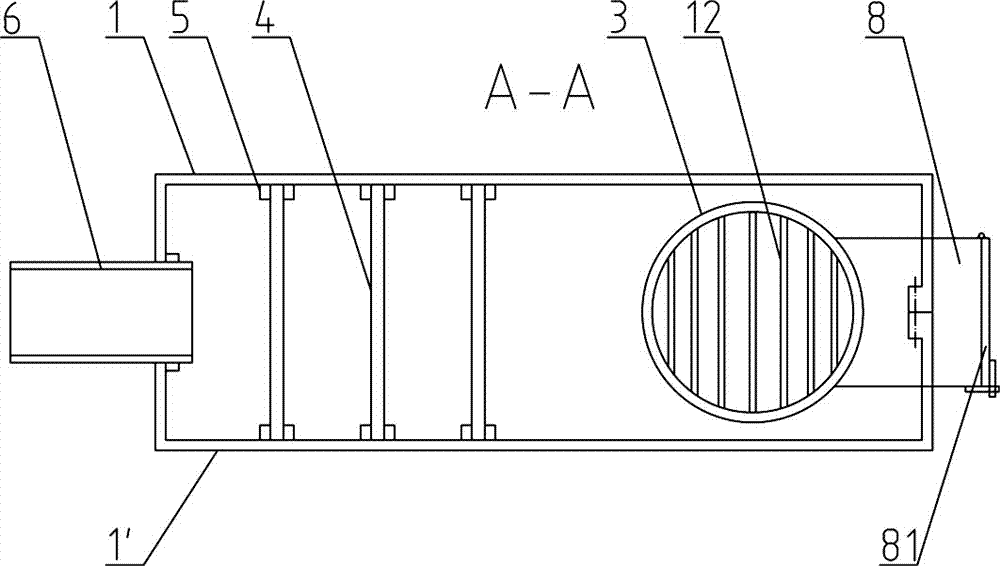

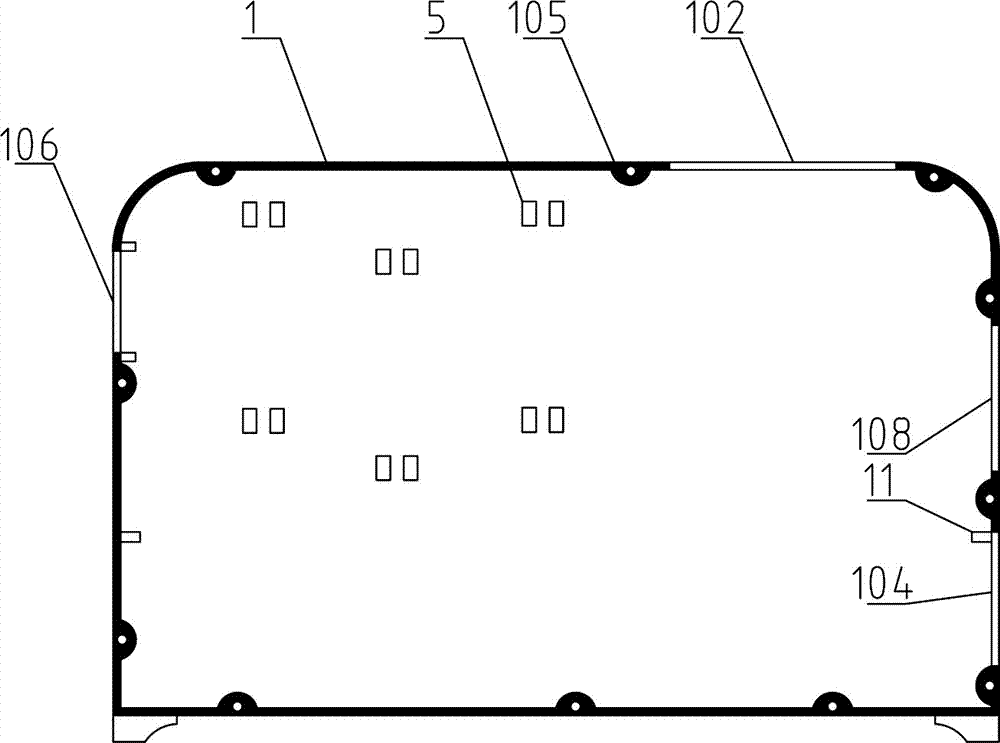

[0041] Such as figure 1 , 11 In 12, a furnace body structure, the furnace body is divided into multiple parts by a vertically split structure, and the parts are connected by connecting pieces. The vertical split structure is adopted, and each split structure is easy to demould. Thereby, a furnace body with higher precision can be obtained, so as to facilitate the later installation. Commonly used structures on the furnace body, such as chimney mouth 106, fire outlet 102, feed inlet 108, ash hopper or air inlet 104, etc., can be passed through once. Casting or die-casting saves the cutting, welding and grinding processes in the later stage, greatly improves labor efficiency and reduces labor intensity.

[0042] Preferably, the division is performed from the position of the midline. Dividing the furnace body into opposing first furnace body 1 and second furnace body 1' by adopting a vertically split structure from the center line;

[0043] The connection mode between the fir...

Embodiment 2

[0063] On the basis of embodiment 1, a kind of combustion furnace adopting above-mentioned furnace body structure is provided with dividing plate 9 in the furnace body, and dividing plate isolates the lower space of furnace body into ash cavity 7, and furnace hearth 3 is positioned at the space of dividing plate 9 in furnace body Above, the inner chamber of the furnace 3 communicates with the ash chamber 7;

[0064] A channel for flue gas to pass is provided between the top of the furnace 3 and the top inner side of the furnace body; a feed channel 8 and a chimney connecting pipe 6 are provided in the furnace body.

[0065] The furnace body is made of aluminum, aluminum alloy or titanium alloy. For the occasions requiring larger firepower, the smoke baffle 4 may not be provided, so as to improve the combustion efficiency under the premise of ensuring the heating effect.

[0066] In a preferred solution, the furnace is a coal furnace 31 made of refractory mud with a thickness ...

Embodiment 3

[0069] On the basis of Embodiments 1 and 2, preferably, the first furnace body 1 and the second furnace body 1' are made of aluminum alloy and have a bisected structure. The first furnace body 1 and the second furnace body 1' are connected by means of interlaced extensions 111 and countersunk bolts. A bite 110 is provided on the end surface where the first furnace body 1 and the second furnace body 1' contact.

[0070] Preferably, the bottom is connected by means of connecting plate 112 and bolts and nuts.

[0071] A fire outlet 102 is provided on the top of the furnace body composed of the first furnace body 1 and the second furnace body 1 ′, and a sliding or rotating fire sealing plate is provided at the position of the fire outlet 102 .

[0072] The inner walls of the first furnace body 1 and the second furnace body 1' are provided with a grid structure 103 or fins 107, and a plurality of supporting blocks 11 are also provided for supporting cast iron or steel partitions 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com