EVA in-mold bubble one-time forming mold and forming method

A technology for forming molds and air bubbles, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low efficiency and complicated manufacturing process, and achieve the effects of high work efficiency, compact structure, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention easier to understand, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

[0026] refer to Figure 1 to Figure 6

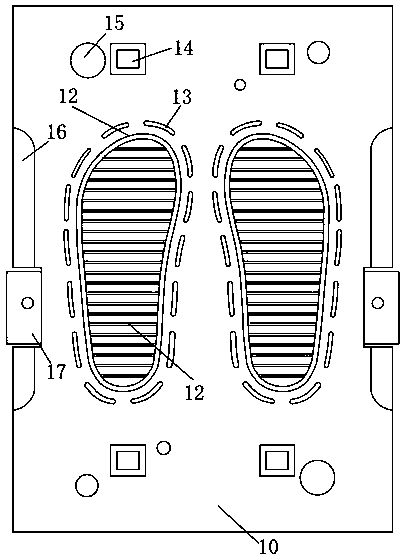

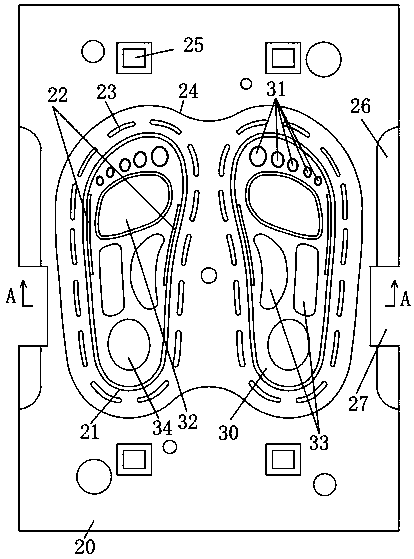

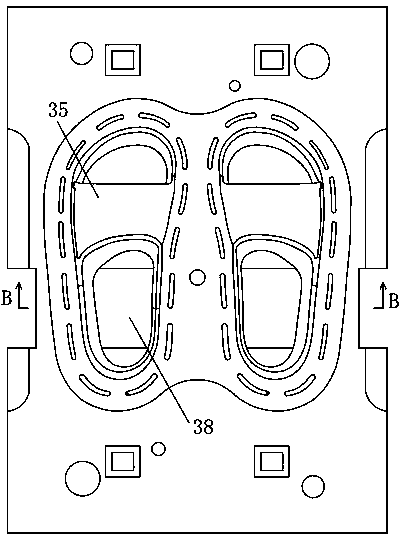

[0027] A kind of EVA in-mold air bubble one-time molding mold, comprises upper template 10 and lower template 20, described upper template is provided with upper mold cavity 11, and described upper mold cavity is provided with the raised part 12 that is used to form anti-slip lines, so The lower template is correspondingly provided with a lower mold cavity 21, and the inner cavity of the lower mold cavity is provided with a concave cavity for forming a convex bulge on the upper surface of the shoe sole. A positioning system and an exhaust system are also arranged between the connected shoe upper forming channel 22 and the upper template and the lower template.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com