Integrated Pit Tunnel Boring Machine

A tunnel boring machine, an integrated technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve problems such as low construction efficiency, easy wear, and reduced construction efficiency, so as to improve tunneling efficiency, reduce manufacturing costs, and reduce preparation costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

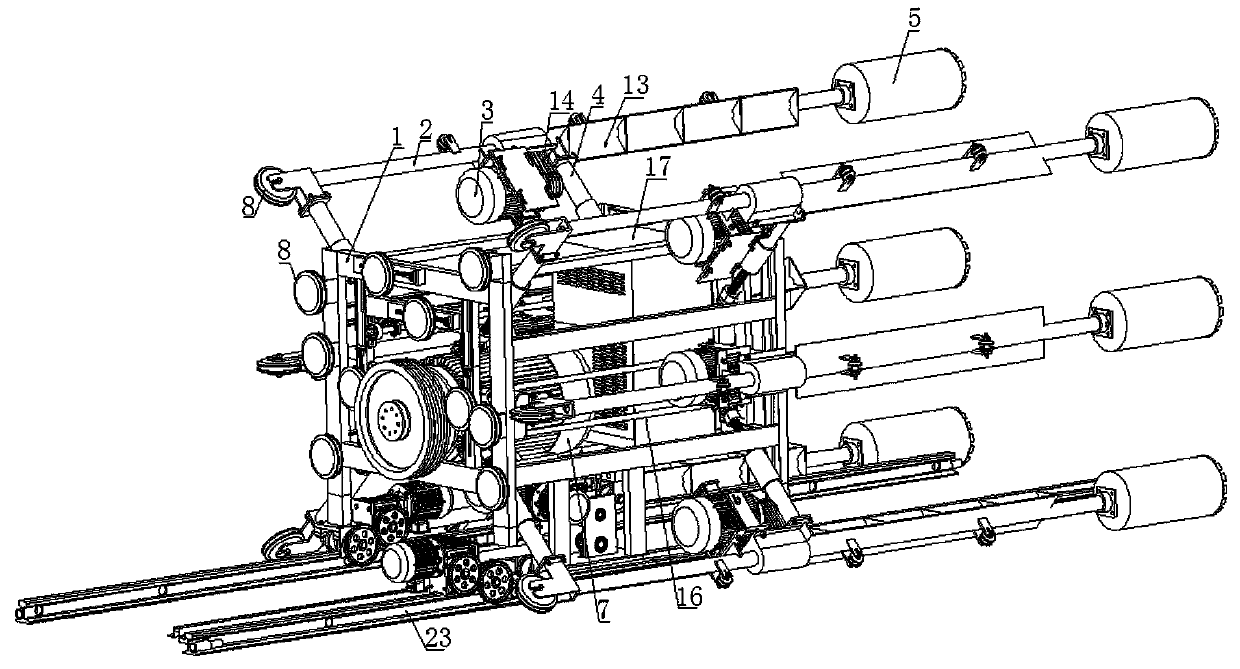

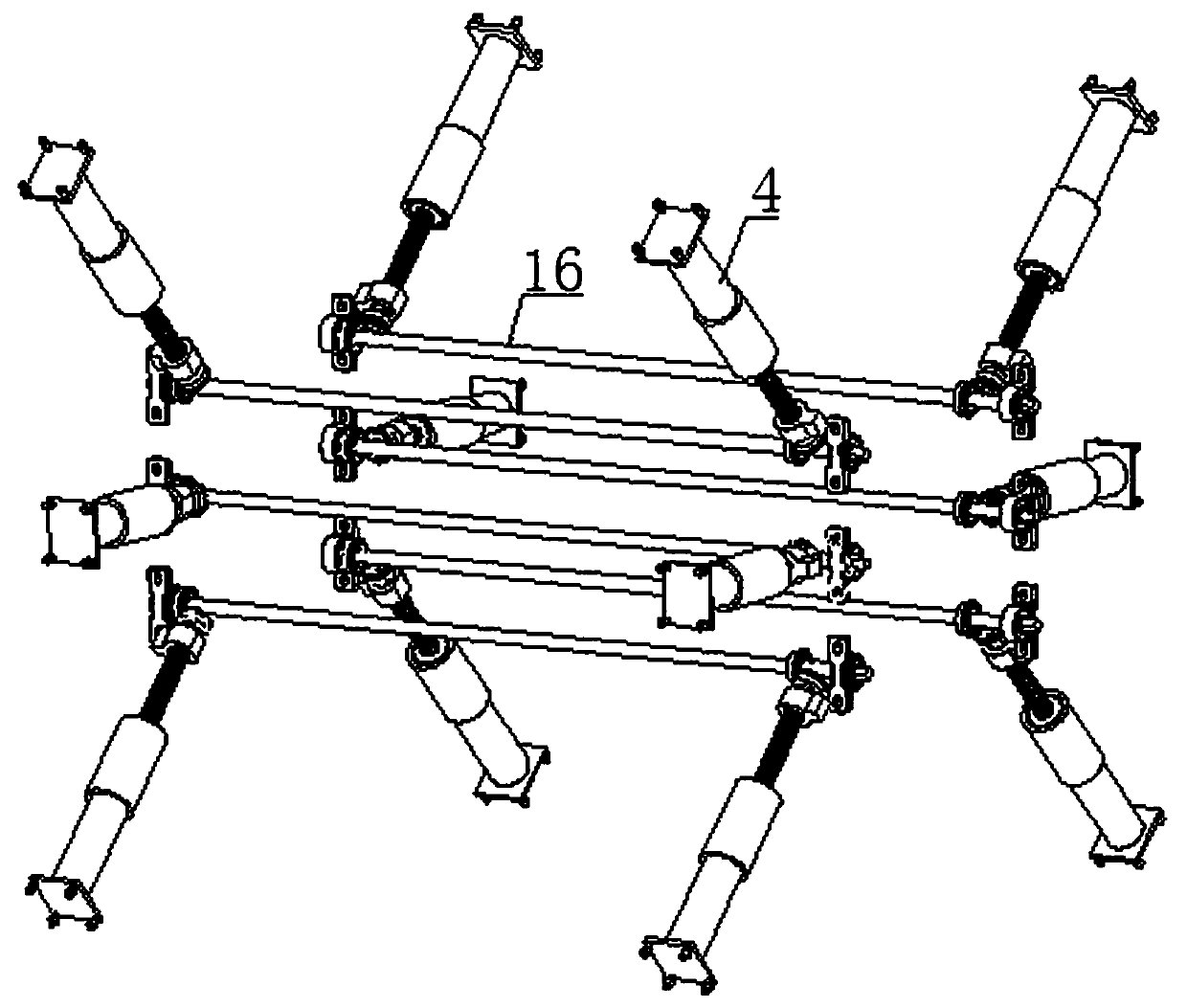

[0046] An integrated pit tunnel boring machine, including a frame 1 and a drilling and sawing mechanism, the drilling and sawing mechanism includes an arm 2, a transmission shaft, a drive motor 3, a telescopic seat 4, a drill barrel 5, and a cutting wheel 6 , main motor 7, saw rope and a plurality of guide wheels 8, the drive motor 3, main motor 7, telescopic seat 4 and a plurality of guide wheels 8 are all fixed on the frame 1, and the arm bar 2 is fixed on the telescopic seat 4, the transmission shaft is sleeved in the arm 2, and the driving motor 3 is connected with the transmission shaft in the arm 2 through a belt 14; when drilling, the drill tube 5 is fixed on the end of the transmission shaft, and the driving motor 3 Drive the drill cylinder 5 to work through the transmission shaft; when sawing, the cutting wheel 6 is movably arranged at the end of the arm bar 2, and the main motor 7 drives the cutting wheel 6 to work through the saw rope and a plurality of guide wheels ...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, the main difference is that: the drive motor 3 is connected to the transmission shaft through the gear transmission gearbox 15 , that is, the drive motor 3 drives the transmission shaft to rotate through the gear transmission transmission gearbox 15 .

Embodiment 3

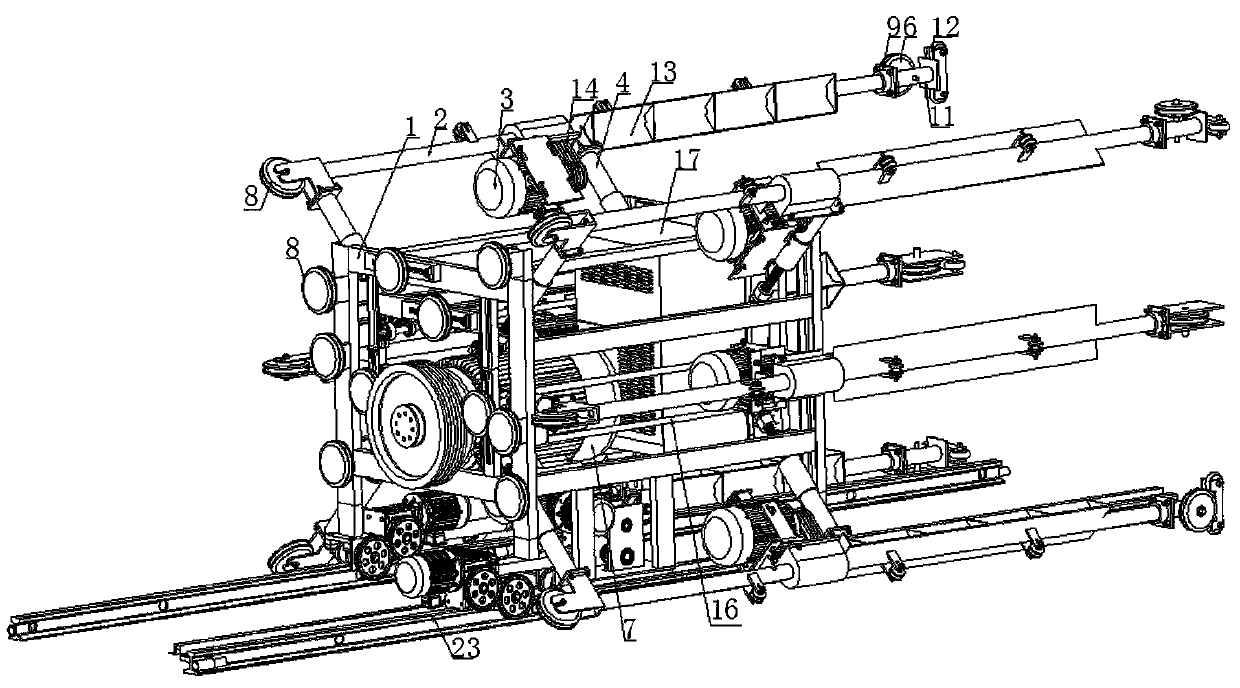

[0057] An integrated pit tunnel boring machine, including a frame 1 and a drilling and sawing mechanism, the drilling and sawing mechanism includes an arm 2, a transmission shaft, a drive motor 3, a telescopic seat 4, a drill barrel 5, and a cutting wheel 6 , main motor 7, saw rope and a plurality of guide wheels 8, the drive motor 3, main motor 7, telescopic seat 4 and a plurality of guide wheels 8 are all fixed on the frame 1, and the arm bar 2 is fixed on the telescopic seat 4, the transmission shaft is sleeved in the arm 2, and the driving motor 3 is connected with the transmission shaft in the arm 2 through a belt 14; when drilling, the drill tube 5 is fixed on the end of the transmission shaft, and the driving motor 3 Drive the drill cylinder 5 to work through the transmission shaft; when sawing, the cutting wheel 6 is movably arranged at the end of the arm bar 2, and the main motor 7 drives the cutting wheel 6 to work through the saw rope and a plurality of guide wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com