Graphene/gallium arsenide solar cell with array micro-nano lens structure and preparation method of graphene/gallium arsenide solar cell

A lens structure and solar cell technology, which is applied in the field of solar cells, can solve the problems of complex manufacturing process, low efficiency, and high cost, and achieve the effects of convenient preparation, wide application range, and anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

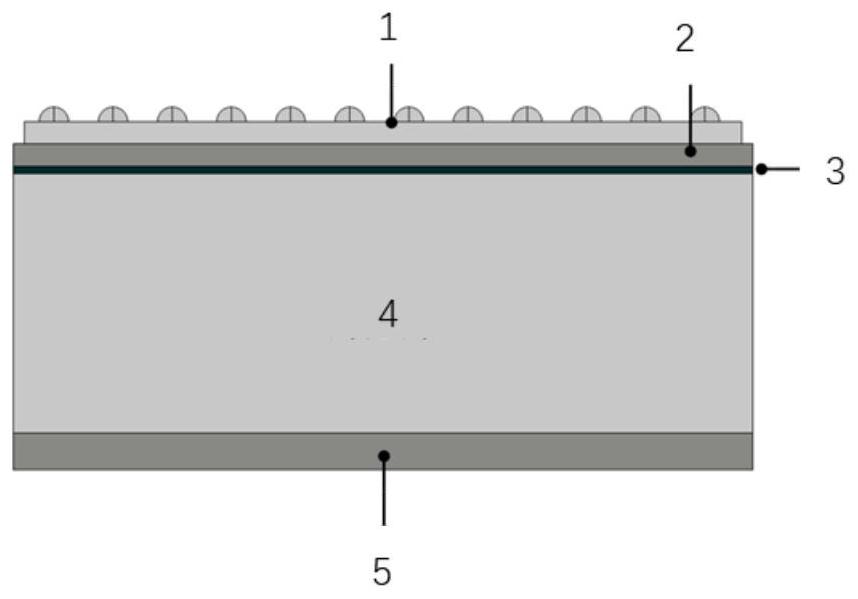

Embodiment 1

[0048] (1) Use acetone ethanol and deionized water to ultrasonically clean the gallium arsenide substrate epitaxial wafer ((100) crystal plane) (the substrate is 2 inches) in sequence, then take out the substrate and dry it with a nitrogen gun; One side of gallium substrate epitaxial wafer is prepared by evaporation and annealing to prepare gold coating as the back electrode;

[0049] (2) Use wet transfer to transfer graphene to the side of the above-mentioned gallium arsenide that has not prepared the electrode; use vacuum-assisted drying to remove moisture; use gold as the electrode material to vapor-deposit on the graphene surface with a thickness of 100nm, a width of 3 μm, and a spacing of 100nm. A fine grid electrode of 300 μm and a main grid electrode with a thickness of 100 nm and a width of 100 μm distributed along the surface boundary of the graphene layer;

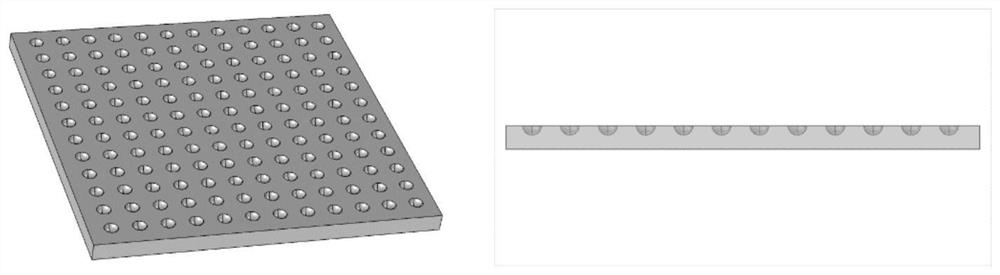

[0050] (3) Add 0.1mL of nano-imprint adhesive (a mixture of GLR Primer tackifier and GLR-Plus UV nano-imprint ...

Embodiment 2

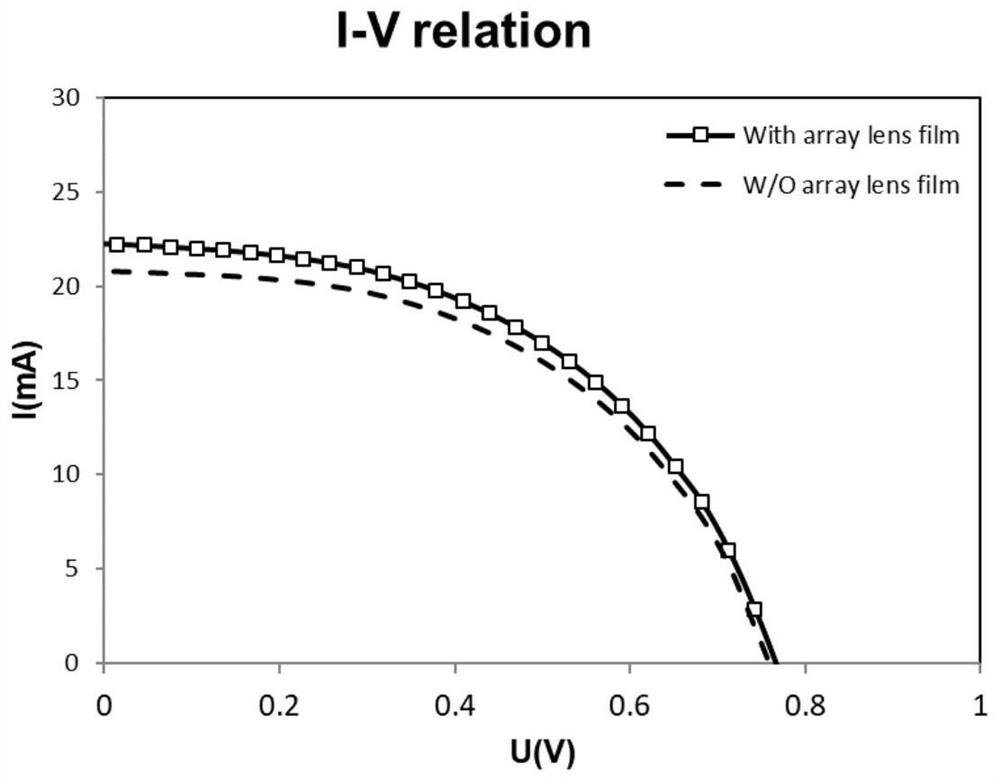

[0057] The difference from Example 1 is that in Example 2, the fine grid pitch of the surface grid electrode is 500 μm, and the thickness of the surface film is changed by controlling the spin-coating time of the embossing glue to 60 s. The pattern parameters of the selected soft film plate are 200nm in diameter, 50nm in thickness, 200nm in pattern array spacing, and 30s of ultraviolet exposure time. Other conditions and preparation methods are the same as in Example 1. The final graphene / gallium arsenide solar cell open circuit voltage V oc is 0.758V, the short-circuit current density I SC 21.3mA cm -2 , the fill factor FF is 50.24%, and the photoelectric conversion efficiency is 8.11%.

Embodiment 3

[0059] The difference from Example 1 is that in Example 3, the spin-coating time of the nanoimprint adhesive is controlled to be 90s, and the pattern parameters of the soft film plate are selected as lens pattern diameter 150nm, thickness 50nm, pattern array spacing 150nm, UV exposure time 90s, other conditions and The preparation method is the same as in Example 1. The final graphene / gallium arsenide solar cell open circuit voltage V oc is 0.758V, the short-circuit current density I SC 22.5mA cm -2 , the fill factor FF is 50.11%, and the photoelectric conversion efficiency is 8.55%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com