Deep groove stone-like paint putty powder

A technology of imitating stone paint and putty powder, applied in the direction of filling slurry, etc., can solve the problems that the bonding force of putty powder is not very strong, affect the appearance and heat preservation, and increase the cost, so as to avoid shrinkage and cracking, improve the thermal insulation effect, Ensure the effect of indoor temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

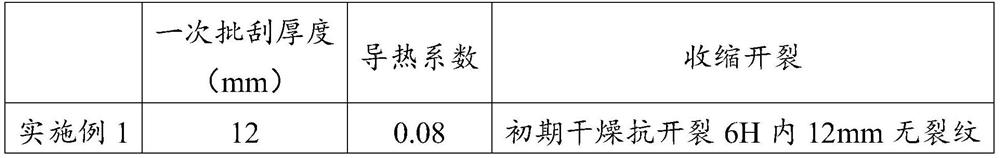

Embodiment 1

[0035] Take 30 parts of 42.5R Portland cement, 50 parts of silica sand, 10 parts of mineral powder filler and 10 parts of perlite.

[0036] In silica sand, the mass ratio of the components with particle size greater than or equal to 40 mesh and less than 80 mesh, and the particle size of components with particle size greater than or equal to 80 mesh and less than or equal to 120 mesh is 1:1.5;

[0037] In the mineral powder filler, the mass ratio of hydroxypropyl methylcellulose, rubber powder, water reducing agent, anti-cracking fiber, wood fiber and starch ether is 4:12:0.3:1:5:0.5;

[0038] The rubber powder is 5044N rubber powder, the water reducing agent is polyhydroxy acid water reducing agent, the anti-cracking fiber is polypropylene short fiber, and the aspect ratio is 6; the wood fiber is lignin, and the aspect ratio is 6; Vibe starch ether, the particle size of perlite is 90 mesh.

[0039] The deep groove imitation stone paint putty powder is obtained after the abov...

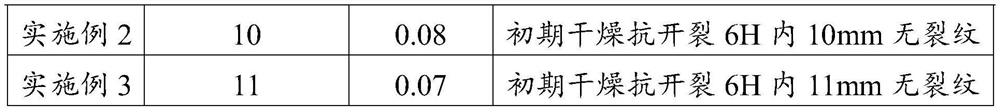

Embodiment 2

[0041] Take 25 parts of 42.5 Portland cement, 55 parts of silica sand, 5 parts of mineral powder filler and 15 parts of vitrified microbeads.

[0042] In the silica sand, the mass ratio of the components with a particle size greater than or equal to 40 mesh and less than 80 mesh, and the particle size of the component with a particle size greater than or equal to 80 mesh and less than or equal to 120 mesh is 1:1.4;

[0043] In the mineral powder filler, the mass ratio of hydroxypropyl methylcellulose, rubber powder, water reducing agent, anti-cracking fiber, wood fiber and starch ether is 3:14:0.2:1.3:4:0.6;

[0044] The rubber powder is 5044N rubber powder, the water reducing agent is polyhydroxy acid water reducing agent, the anti-cracking fiber is polypropylene short fiber, and the aspect ratio is 5; the wood fiber is lignin, and the aspect ratio is 7; Vibe starch ether, the particle size of vitrified microbeads is 80 mesh.

[0045] The deep groove imitation stone paint pu...

Embodiment 3

[0047] Take 35 parts of 42.5R Portland cement, 45 parts of silica sand, 15 parts of mineral powder filler, and 5 parts of vitrified microbeads.

[0048] In the silica sand, the mass ratio of the components with a particle size greater than or equal to 40 mesh and less than 80 mesh, and the particle size of the component with a particle size greater than or equal to 80 mesh and less than or equal to 120 mesh is 1:1.6;

[0049] In the mineral powder filler, the mass ratio of hydroxypropyl methylcellulose, rubber powder, water reducing agent, anti-cracking fiber, wood fiber and starch ether is 5:11:0.35:0.9:6:0.3;

[0050] The rubber powder is 5044N rubber powder, the water reducing agent is polyhydroxy acid water reducing agent, the anti-cracking fiber is polypropylene short fiber, and the aspect ratio is 7; the wood fiber is lignin, and the aspect ratio is 5; Vibe starch ether, the particle size of vitrified microbeads is 70 mesh.

[0051] The deep groove imitation stone paint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com