Combination cutter

A composite knife and tool holder technology, applied in the field of composite knives, can solve problems such as affecting the processing cost and efficiency, the overall structure is cumbersome, and the processing efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

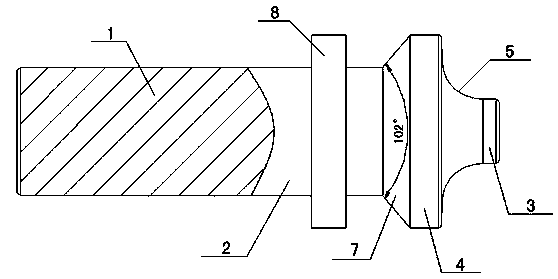

[0011] See attached figure 1 , the present invention proposes a composite knife, including a knife handle 1 and a knife head, one end of the knife handle 1 is connected to one end of a support rod 2 by welding, and the right end surface is an arc-shaped convex surface, and the support rod 2 The left end surface is an arc-shaped concave surface matching with the arc-shaped convex surface, and the arc-shaped surface is welded together, which effectively avoids the phenomenon that the plane is not firmly bonded and is easy to break. Different from general V-shaped welding, the combination of curved surfaces is not conducive to the formation of stress concentration, and the welding effect is better.

[0012] The other end of the support rod 2 is connected to the cutter head. The cutte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com