Anti-pricking memory adhesive as well as preparation method and application thereof

A memory and anti-puncture technology, which is applied in the field of polymer chemical engineering, can solve the problems of increasing tire weight, vehicle energy consumption, increasing the use of memory glue, and increasing user costs, so as to simplify the explosion-proof protection procedures and increase recycling. , the effect of enhancing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

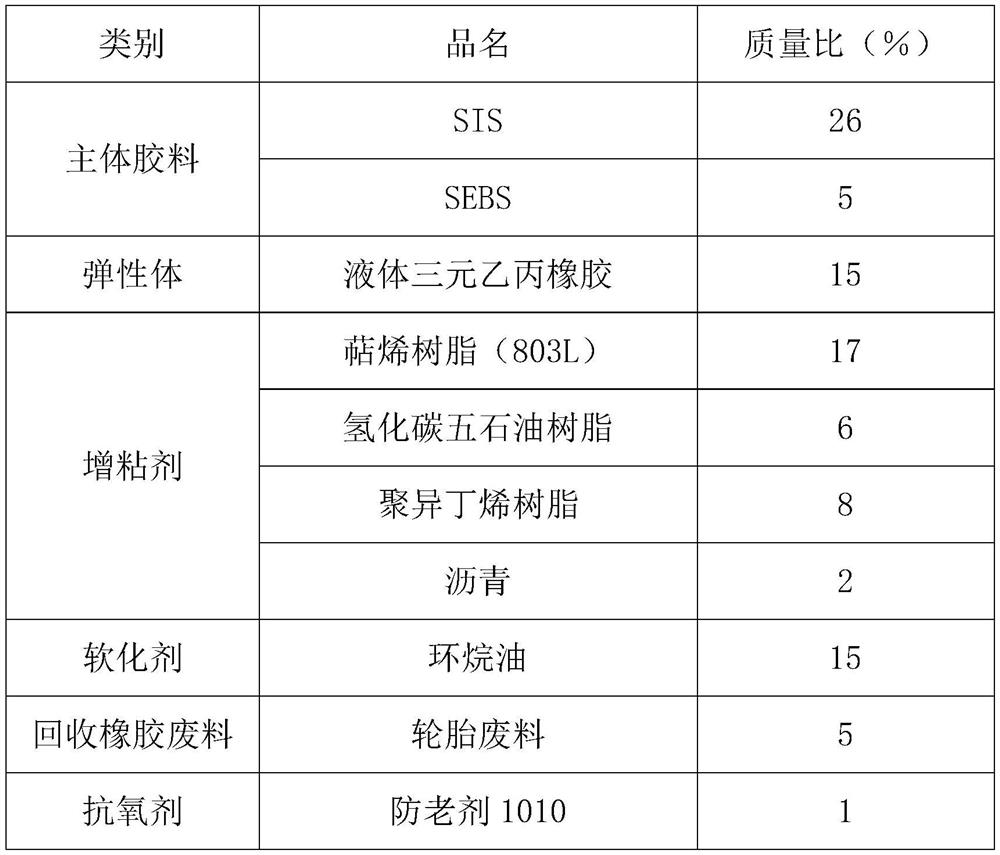

[0029] This embodiment provides an anti-tack memory glue, which is prepared from the following formula by mass percentage: 31% main rubber material; 15% elastomer; 33% tackifier; 15% softener; 5% recycled rubber waste ; 1% antioxidant, the specific ingredients are shown in Table 1.

[0030] The preparation method of the anti-tear memory glue is as follows: according to the composition and ingredients in Table 1, they are added into the reaction kettle and mixed evenly. Then heat the mixture to 180-195°C, keep stirring the mixture for 1 hour in this state, pour it out and cool it to room temperature to form lumps.

[0031] The anti-tie memory glue composition of table 1 embodiment 1

[0032]

[0033] The specific properties of the anti-tie memory glue of this embodiment are as follows: rebound height: 360mm; peel strength: average 2.19N / mm, maximum 2.43N / mm; softening point: 123°C; tensile strength: 0.48MPa; Length: 850%.

[0034] Melt the anti-jamming memory glue of this...

Embodiment 2

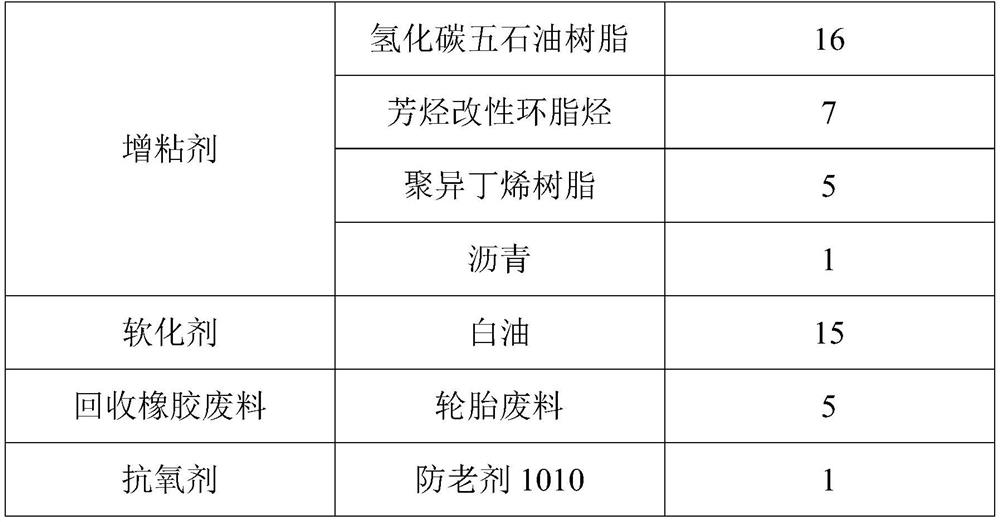

[0036] This embodiment provides an anti-pricking memory glue, which is prepared from the following formula by mass percentage: 30% main rubber material; 20% elastomer; 29% tackifier; 15% softener; 5% recycled rubber waste; 1 % Antioxidant. The specific ingredients are shown in Table 2.

[0037] The preparation method of the anti-tear memory glue is as follows: according to the composition and ingredients in Table 2, they are added into the reaction kettle and mixed evenly. Then heat the mixture to 180-195°C, keep stirring the mixture for 2 hours in this state, pour it out and cool it to room temperature to form a lump.

[0038] The anti-tie memory glue composition of table 2 embodiment 2

[0039]

[0040]

[0041] The specific properties of the anti-tie memory glue of this embodiment are as follows: rebound height: 330mm; peel strength: average 2.12N / mm, maximum 2.36N / mm; softening point: 119°C; tensile strength: 0.41MPa; Length: 800%.

[0042] Melt the anti-jaw memo...

Embodiment 3

[0044] This embodiment provides an anti-pricking memory glue, which is prepared from the following formula by mass percentage: 30% main rubber; 20% elastomer; 34% tackifier; 10% softener; 5% recycled rubber rubber; 1% antioxidant, the specific ingredients are shown in Table 3.

[0045] The preparation method of the anti-jaw memory glue is as follows: according to the composition and ingredients in Table 3, add them into the reaction kettle and mix evenly.

[0046] Then heat the mixture to 180-195°C, keep stirring the mixture for 2 hours in this state, pour it out and cool it to room temperature to form a lump.

[0047] The anti-tie memory glue composition of table 3 embodiment 3

[0048]

[0049] The specific properties of the anti-tie memory glue of this embodiment are as follows: rebound height: 350mm; peel strength: average 2.14N / mm, maximum 2.48N / mm; softening point: 121°C; tensile strength: 0.43MPa; Length: 850%.

[0050]Melt the anti-tie memory glue of this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com