Polyurethane sole resin capable of improving adhesion as well as preparation method and application thereof

A technology for shoe soles and polyurethane is applied in the field of resin and preparation of polyurethane soles, which can solve problems such as degumming of uppers and soles, and achieve the effect of improving the adhesiveness of resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

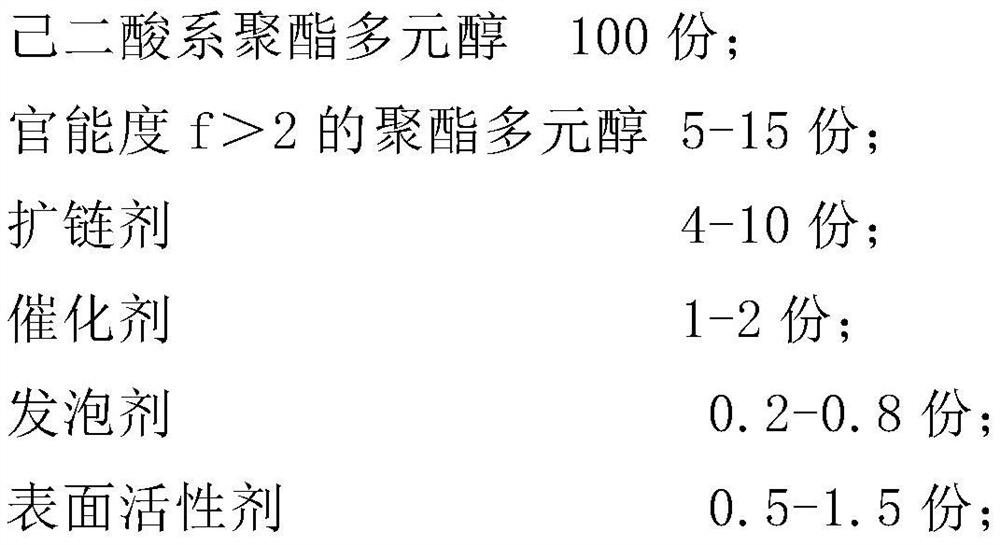

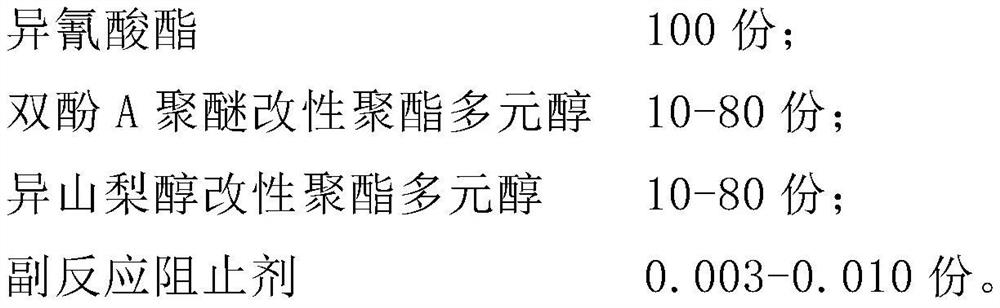

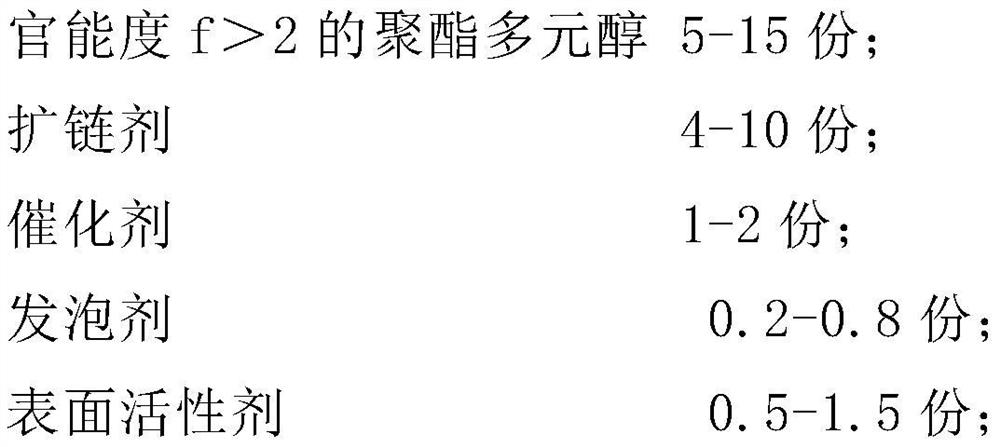

Method used

Image

Examples

Embodiment 1

[0038] Preparation of bisphenol A polyether modified polyester polyol P1: 1.584kg of BPA-2EO, 0.365kg of diethylene glycol, 0.213kg of ethylene glycol and 1.460kg of adipic acid were protected under nitrogen and 0.5wt‰ catalyst titanic acid In the presence of tetraisopropyl ester, carry out esterification reaction at 140-200°C, and distill water under normal pressure at the same time, wait for the acid value to drop to 10-20mgKOH / g, carry out polycondensation reaction at 200-240°C, and remove the product by distillation under reduced pressure for 5 hours A trace amount of water to obtain a total of 3.255 kg of bisphenol A polyether modified polyester polyol P1 with an acid value of 0.5 mgKOH / g and a hydroxyl value of 45 mgKOH / g.

[0039] Preparation of isosorbide-modified polyester polyol P2: 0.648kg of isosorbide, 0.353kg of diethylene glycol, 0.207kg of ethylene glycol and 1.460kg of adipic acid under nitrogen protection and 0.5wt‰ catalyst tetraisotitanate In the presence o...

Embodiment 2

[0041] Preparation of bisphenol A polyether modified polyester polyol P3: 1.801kg of BPA-6EO, 0.510kg of diethylene glycol, 0.224kg of ethylene glycol and 1.460kg of adipic acid were protected under nitrogen and 0.5wt‰ catalyst titanic acid In the presence of tetraisopropyl ester, carry out esterification reaction at 140-200°C, and distill water under normal pressure at the same time, wait for the acid value to drop to 10-20mgKOH / g, carry out polycondensation reaction at 200-240°C, and remove the product by distillation under reduced pressure for 5 hours A trace amount of water was obtained to obtain a total of 3.540 kg of bisphenol A polyether modified polyester polyol P3 with an acid value of 0.5 mgKOH / g and a hydroxyl value of 55 mgKOH / g.

[0042] Preparation of isosorbide-modified polyester polyol P4: 0.330kg of isosorbide, 0.499kg of diethylene glycol, 0.280kg of ethylene glycol and 1.460kg of adipic acid were placed under nitrogen protection and 0.5wt‰ catalyst tetraisoti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com