Flange component strengthened at root of flexible waveguide rubber sheath

A technology of rubber sheath and soft waveguide, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of metal flange and rubber cracking, and achieve the effect of improving cost advantages, reducing the risk of degumming, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

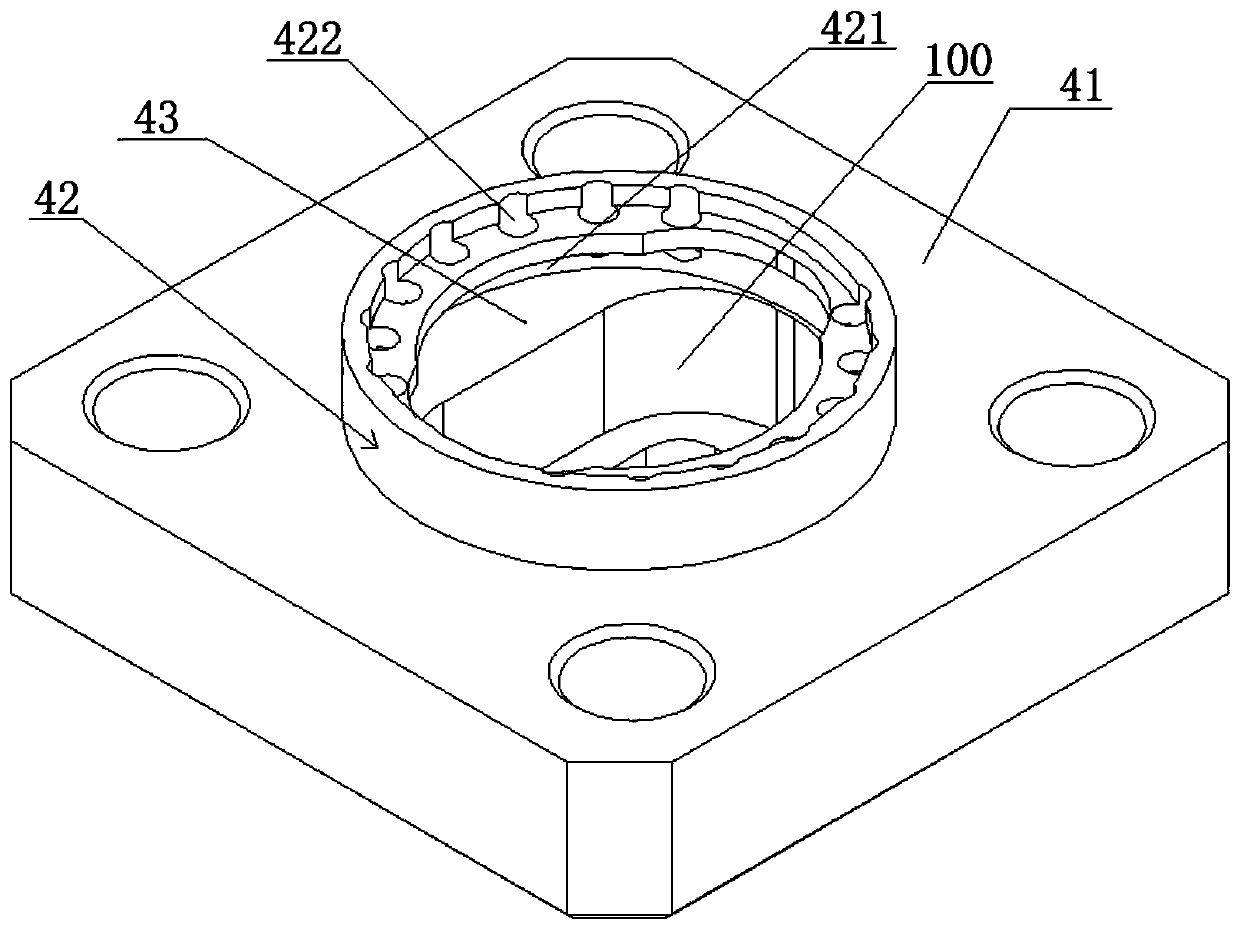

[0029] Such as figure 1 As shown, the flange member reinforced at the root of the soft waveguide rubber sheath includes: a flange body 41 , a rubber engagement ring 42 , a groove 421 , and a plurality of rubber locking holes 422 .

[0030] The flange body 41 is sheet-shaped with a waveguide hole 100 in the middle.

[0031] The rubber engaging ring 42 is fixedly arranged on one side surface of the flange body 41 , and the shape of the rubber engaging ring 42 is ring. Such as figure 1 As shown, a first bonding area 43 is formed between the ring and the flange body.

[0032] The groove 421 is opened on the inner side of the connection between the rubber joint ring 42 and the flange body.

[0033] A plurality of rubber locking holes 422 are longitudinally opened and distributed on the inner wall of the rubber engagement ring, communicating with the groove 421 .

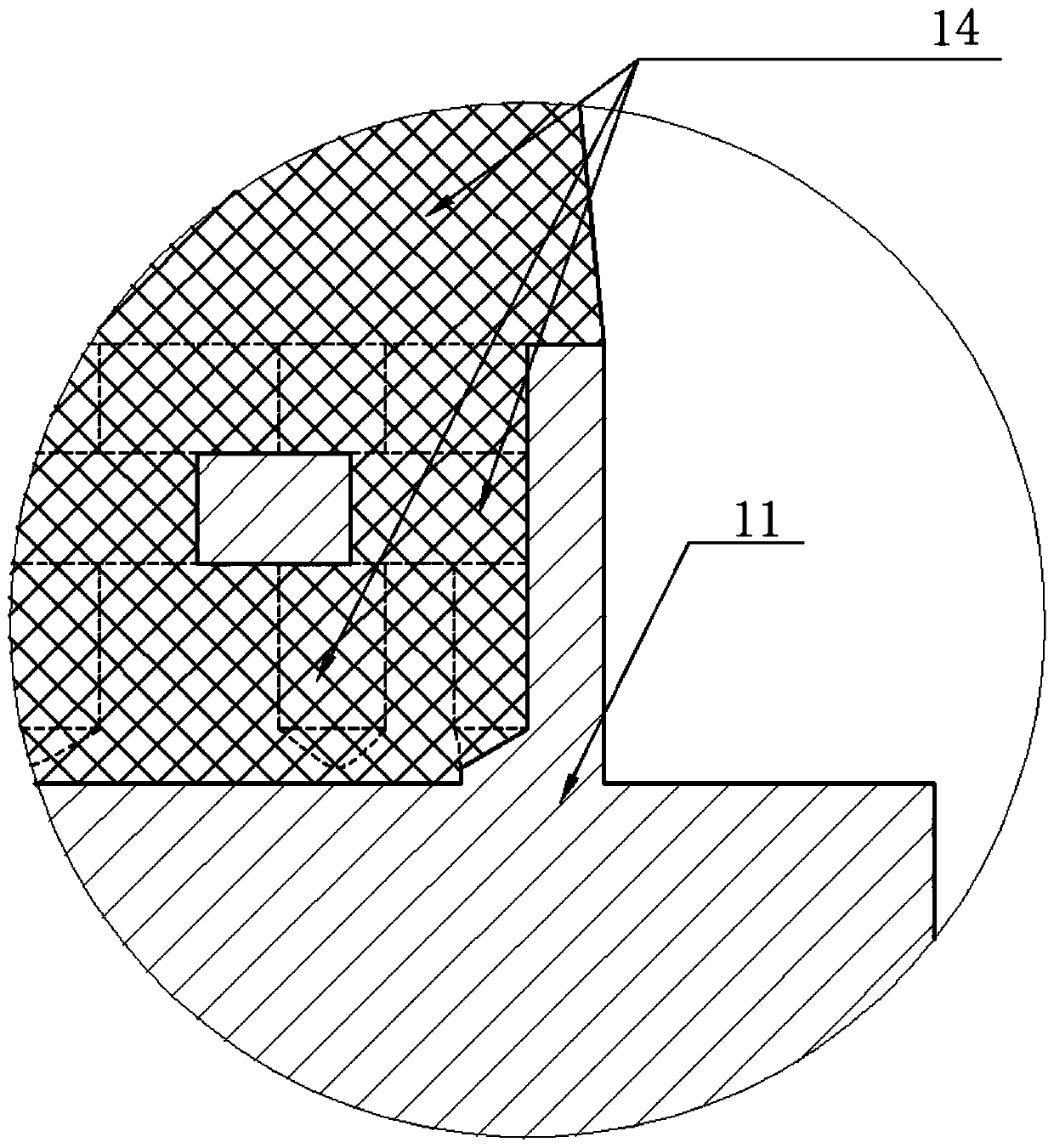

[0034] The rubber sheath 14 is connected with the rubber engaging ring 42, such as image 3 As shown, the rubber i...

Embodiment 2

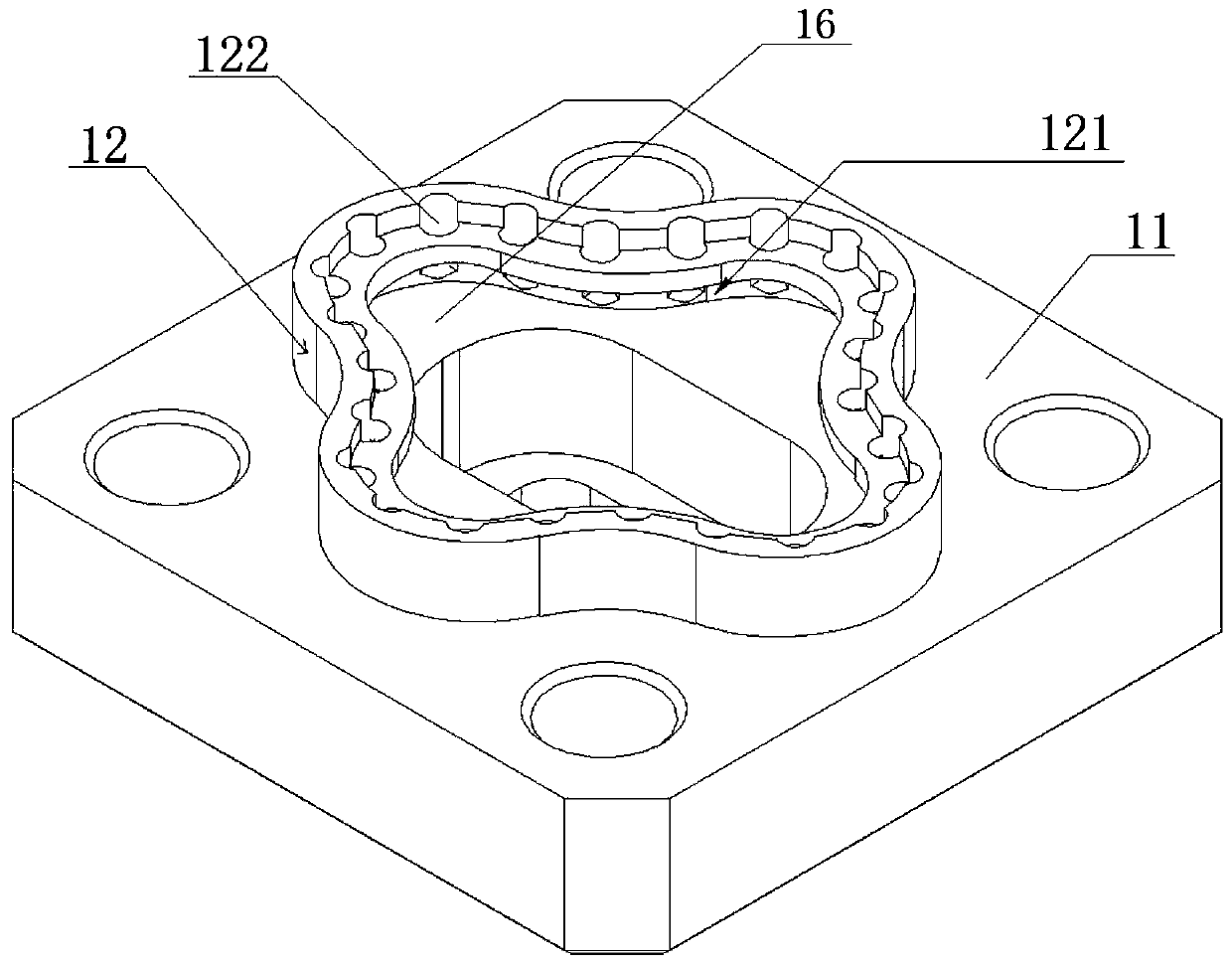

[0036] Such as figure 2 As shown, the flange member reinforced at the root of the soft waveguide rubber sheath includes: a flange body 11 , a rubber joint ring 12 , a groove 121 , and a plurality of rubber locking holes 122 .

[0037] The flange body 11 is sheet-shaped with a waveguide hole in the middle.

[0038] The rubber joint ring 12 is fixedly arranged on one side surface of the flange body 11 , and the shape of the rubber joint ring 12 is a hollow cross. Such as figure 2 and Figure 5 As shown, a second bonding area 16 is formed between the hollow cross and the flange body. The area of the second bonding area 16 is as Figure 5 Shown in the shaded part.

[0039] The groove 121 is opened on the inner side of the connection between the rubber joint ring 12 and the flange body.

[0040] A plurality of rubber locking holes 122 are longitudinal holes distributed on the inner wall of the rubber engagement ring and communicated with the groove 121 .

[0041] The rub...

Embodiment 3

[0045] Such as Figure 7 As shown, the shape of the rubber joint ring 22 is generally a rectangle, but at the four sides of the rectangle, there are outwardly protruding arcs, and a third bonding area 24 is formed between the outwardly protruding arcs and the flange body. A plurality of rubber locking holes 23 are also opened on the rubber engaging ring 22 .

[0046] The connection mode between the flange body and the rubber sheath in this embodiment is the same as that in the above two embodiments.

[0047] In this embodiment, also, the rubber in the rubber sheath can be poured into the groove and the rubber locking hole 23 . Therefore, the connection between the rubber sheath and the flange body 21 is more firm.

[0048] The traditional flange structure needs to process multiple surfaces, and multiple clamping and positioning are required during processing, and the processing process is cumbersome. In this embodiment, a traditional rectangular flange is taken as an exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com