Minced pork processing equipment

A technology of processing equipment and minced meat, which is applied in the direction of meat processing equipment, processed meat, slaughtering, etc., can solve the problems of low work efficiency, inconvenient disassembly and maintenance, complex structure, etc. The effect of uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

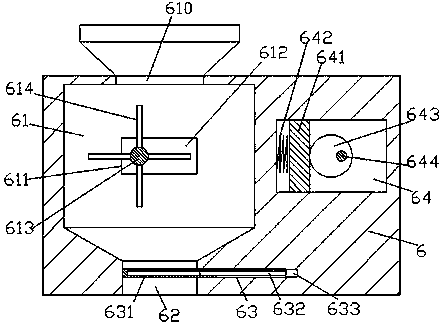

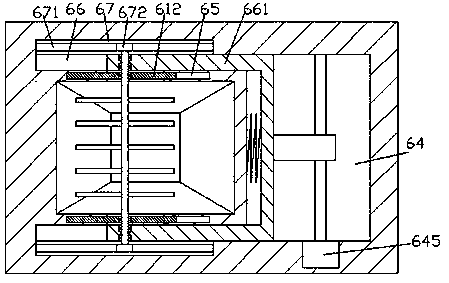

[0014] Combine below Figure 1-Figure 4 The present invention will be described in detail.

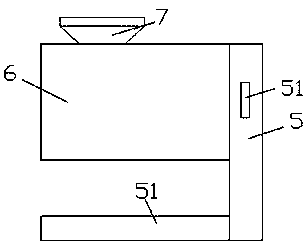

[0015] refer to Figure 1-Figure 4 , a minced meat processing equipment according to an embodiment of the present invention, comprising a support plate 5 and an outer frame 6 fixedly installed on the left end of the support plate 5, and the front and rear end surfaces of the support plate 5 are mirrored with hand-carrying frames 51 respectively. , the hand lift frame 51 is fixedly connected with the support plate 5, the outer frame 6 is provided with a minced meat chamber 61, and the top end surface of the outer frame 6 on the upper side of the minced meat chamber 61 is fixed with a loading bucket 7, the inner top wall of the minced meat chamber 61 is provided with a delivery chamber 610 communicated with the loading bucket 7, and the bottom end surface of the outer frame 6 on the lower side of the minced meat chamber 61 is provided with the minced meat chamber 61. Meat cavity 61 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com