An elevator that can run vertically and horizontally

A cycle operation, horizontal technology, applied in the field of elevators, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

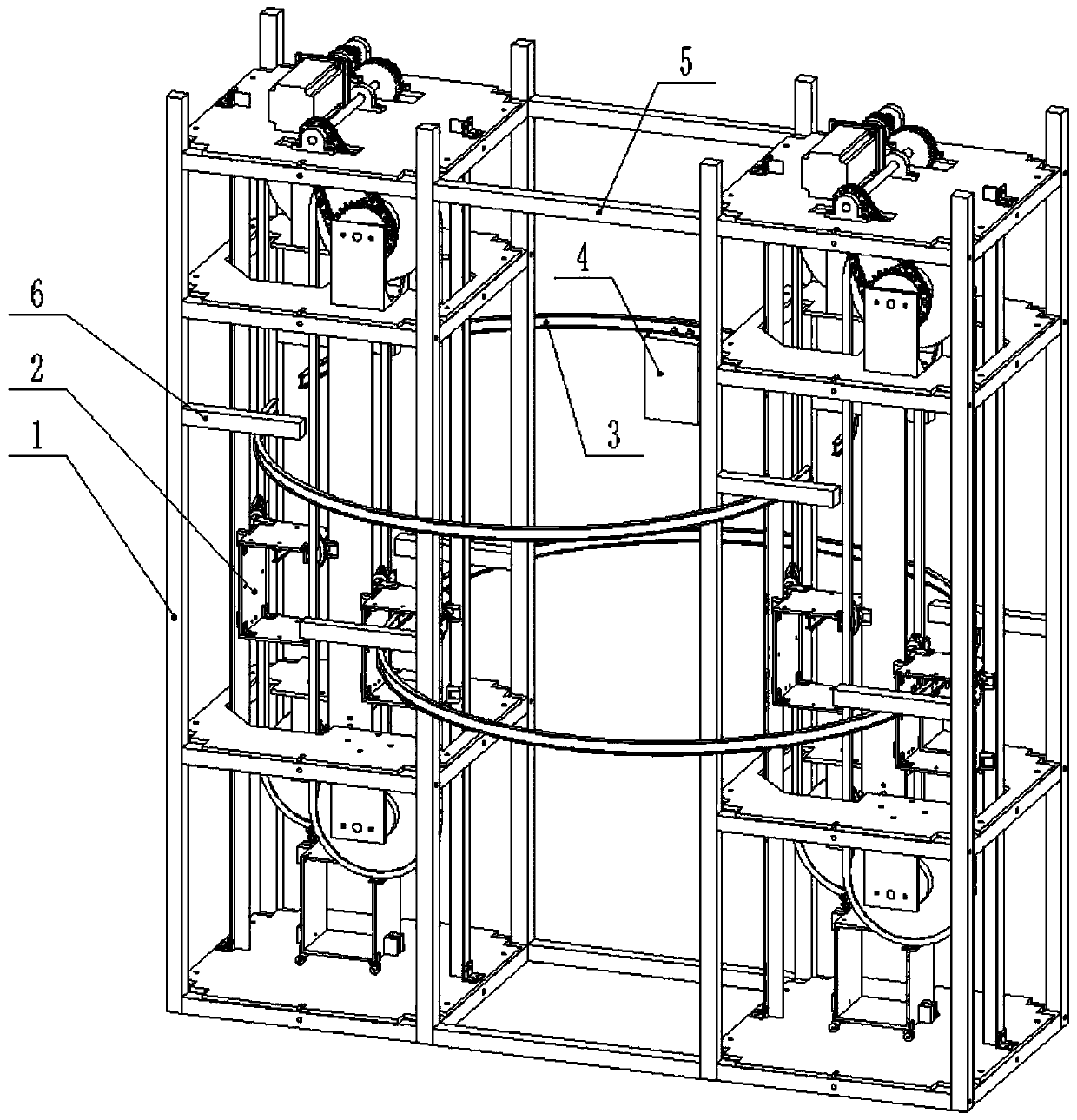

[0021] An elevator that can run vertically and horizontally is composed of a shaft 1, a vertical car 2, a circular track 3, a horizontal car 4, a connecting rod 5 and a track frame 6, and the number of the shaft 1 is two group or more than two groups, the connecting frame rod 5 is connected to multiple sets of wells 1, the vertical car 2 is placed inside the well 1, the circular track 3 is connected to multiple sets of wells through the track frame 6, and the Horizontal car 4 can slide on ring track 3.

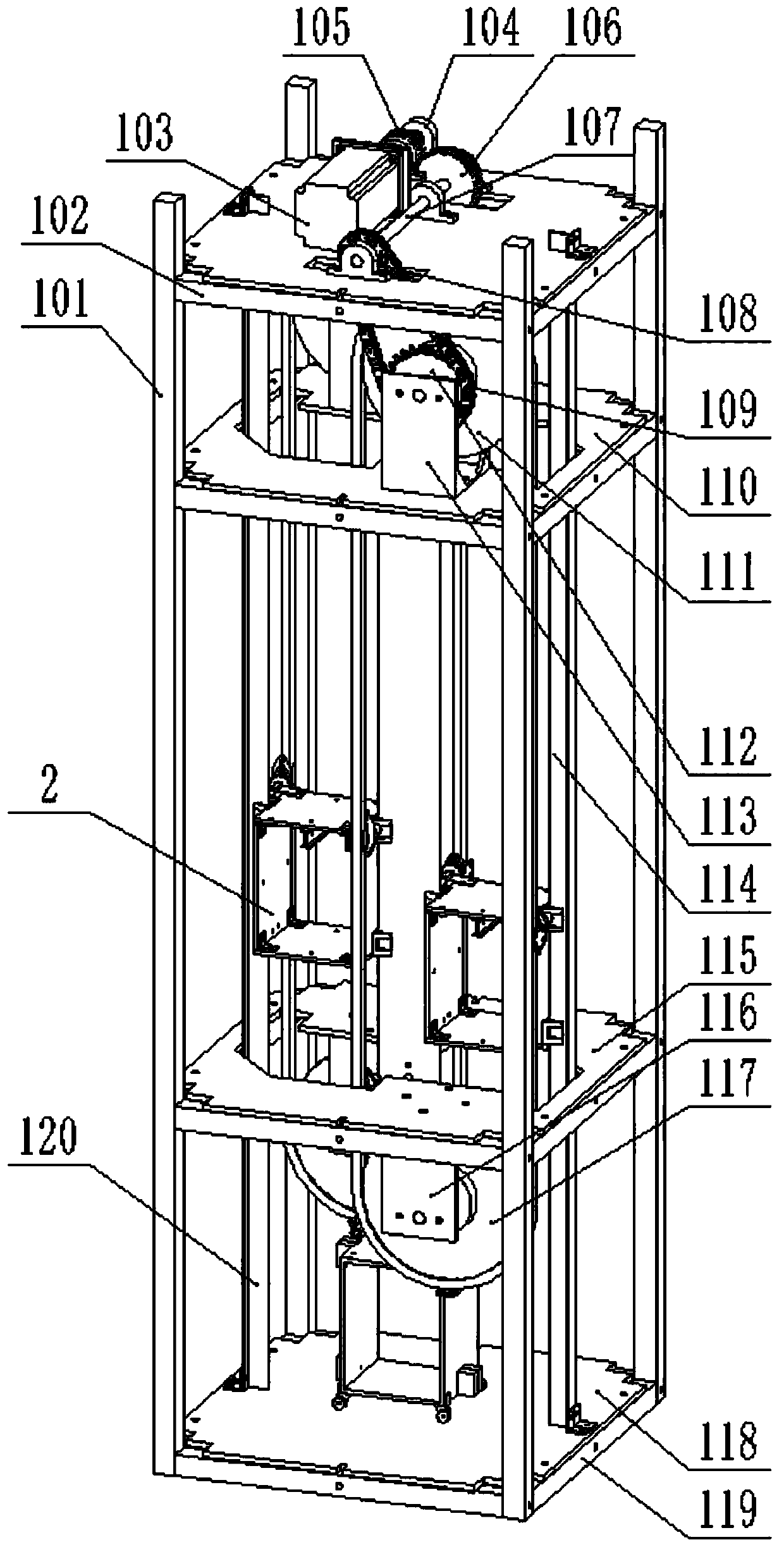

[0022] Further, the hoistway 1 is composed of a vertical bar 101, an upper plate 102, a stepping motor 103, a gear seat 104, a pinion 105, a large gear 106, a gear shaft 107, a small sprocket 108, a short chain 109, an upper Two flat plates 110, the first large sprocket wheel 111, the middle sprocket wheel 112, the first sprocket wheel frame 113, the long chain 114, the next two flat plates 115, the second sprocket wheel frame 116, the second large sprocket wheel 117, the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com