Threading guide plate platform device suitable for various working conditions as well as use method thereof

A guide table and belt threading technology, applied in the field of belt threading guide table, can solve the problems of inability to realize the coiling function, damage to the belt, etc., and achieve the effects of simple structure, no installation space, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

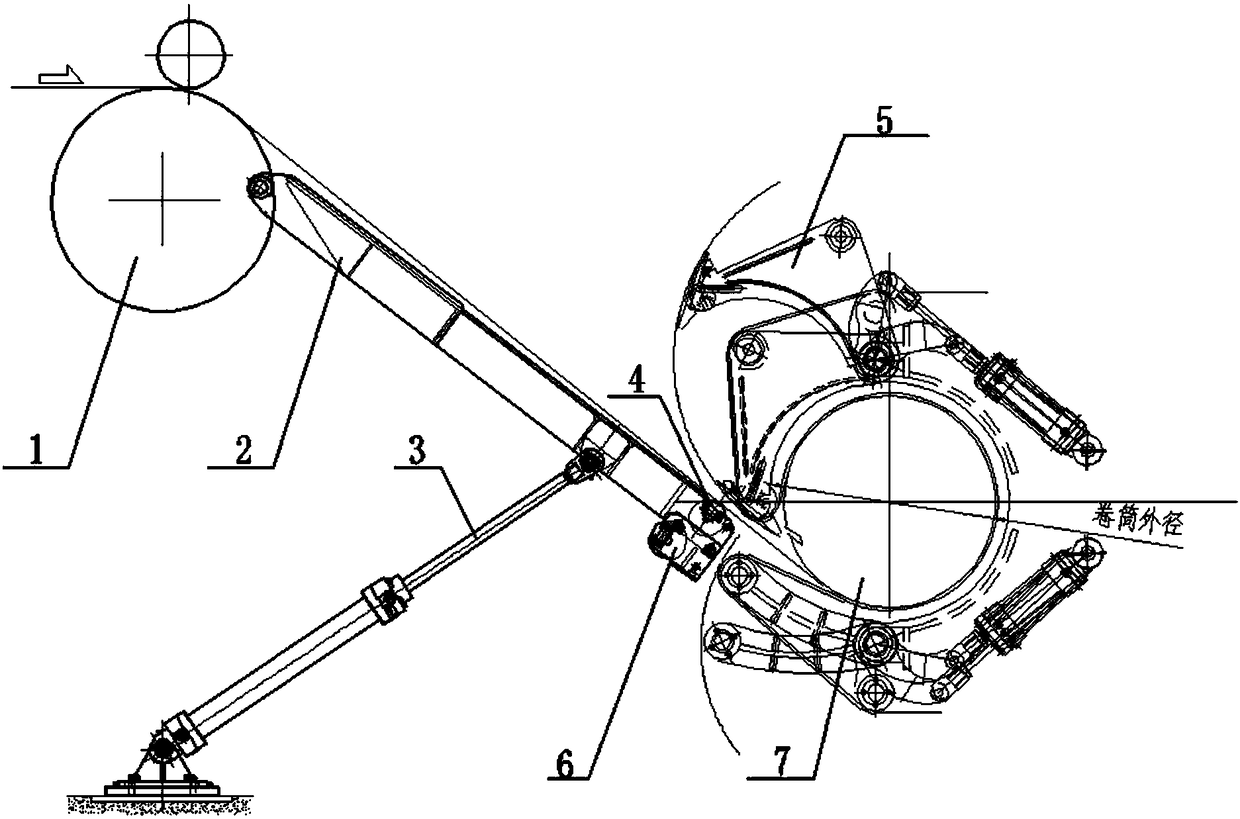

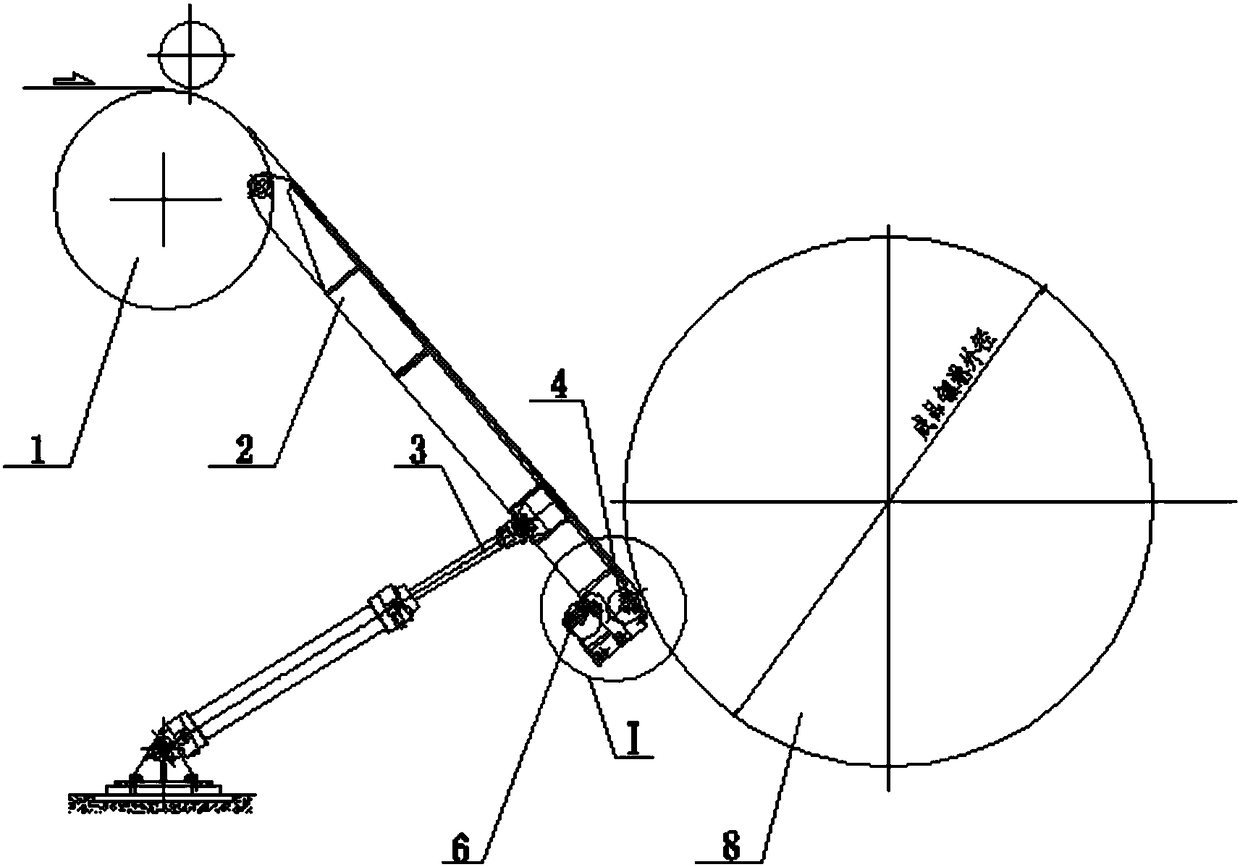

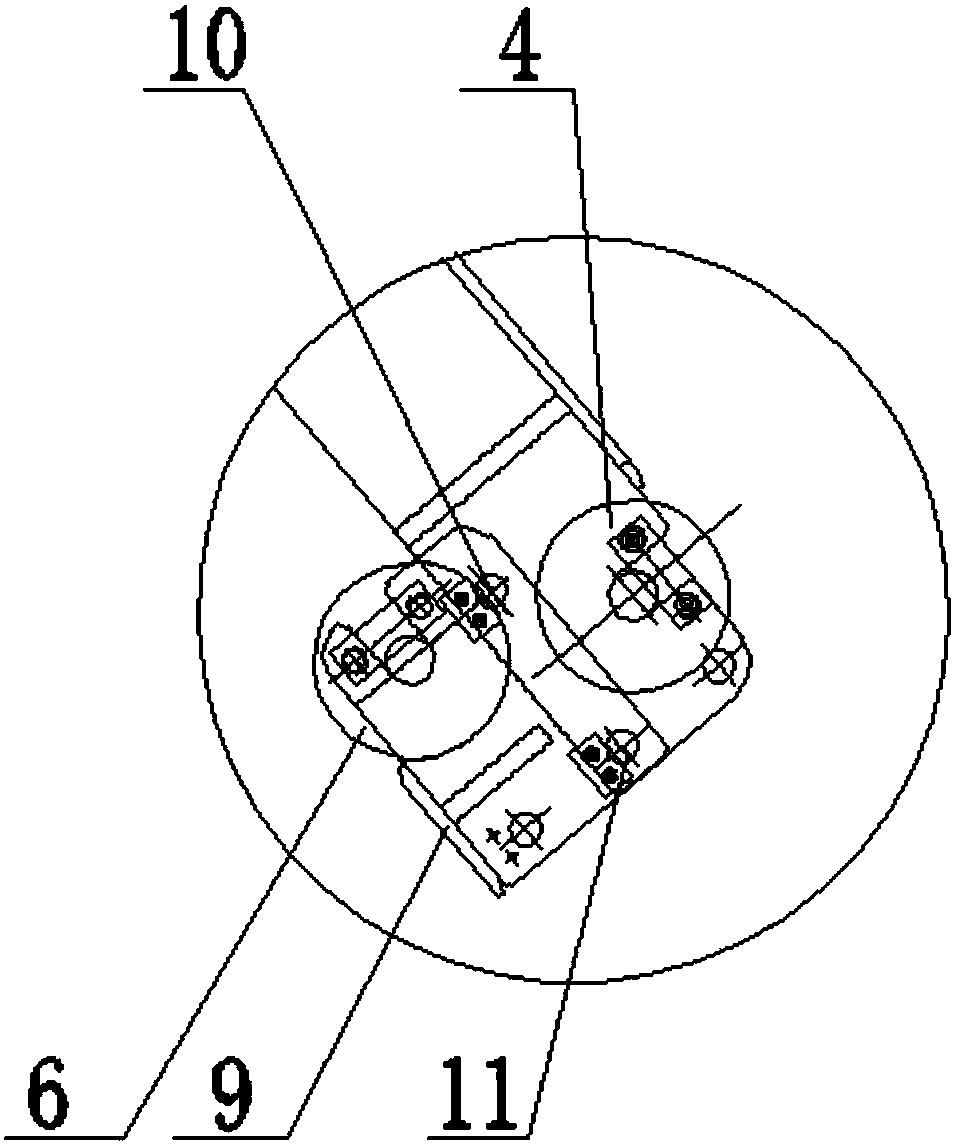

[0023] Such as Figure 1-Figure 7 As shown, a strip threading guide table device suitable for various working conditions is used to guide the strip steel from the steering pinch roller 1 into the coiler drum 7 to be coiled into coils. The device includes a swing frame 2 and a hydraulic cylinder 3 And the first pressure roller 4 and the second pressure roller 6; one end of the swing frame 2 is hinged with the steering pinch roller 1, and its other end is arranged at the entrance of the coiler drum 7, and the head of the hydraulic cylinder 3 is connected with the swing frame The other end of 2 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap