Plastic pipe bending machine

A pipe bending machine and plastic technology, applied in the field of plastic pipe bending machines, can solve the problems of high manufacturing cost, complex structure of the pipe bending machine, inability to perform convenient and quick pipe bending actions, etc., and achieve the effect of convenient operation and power saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

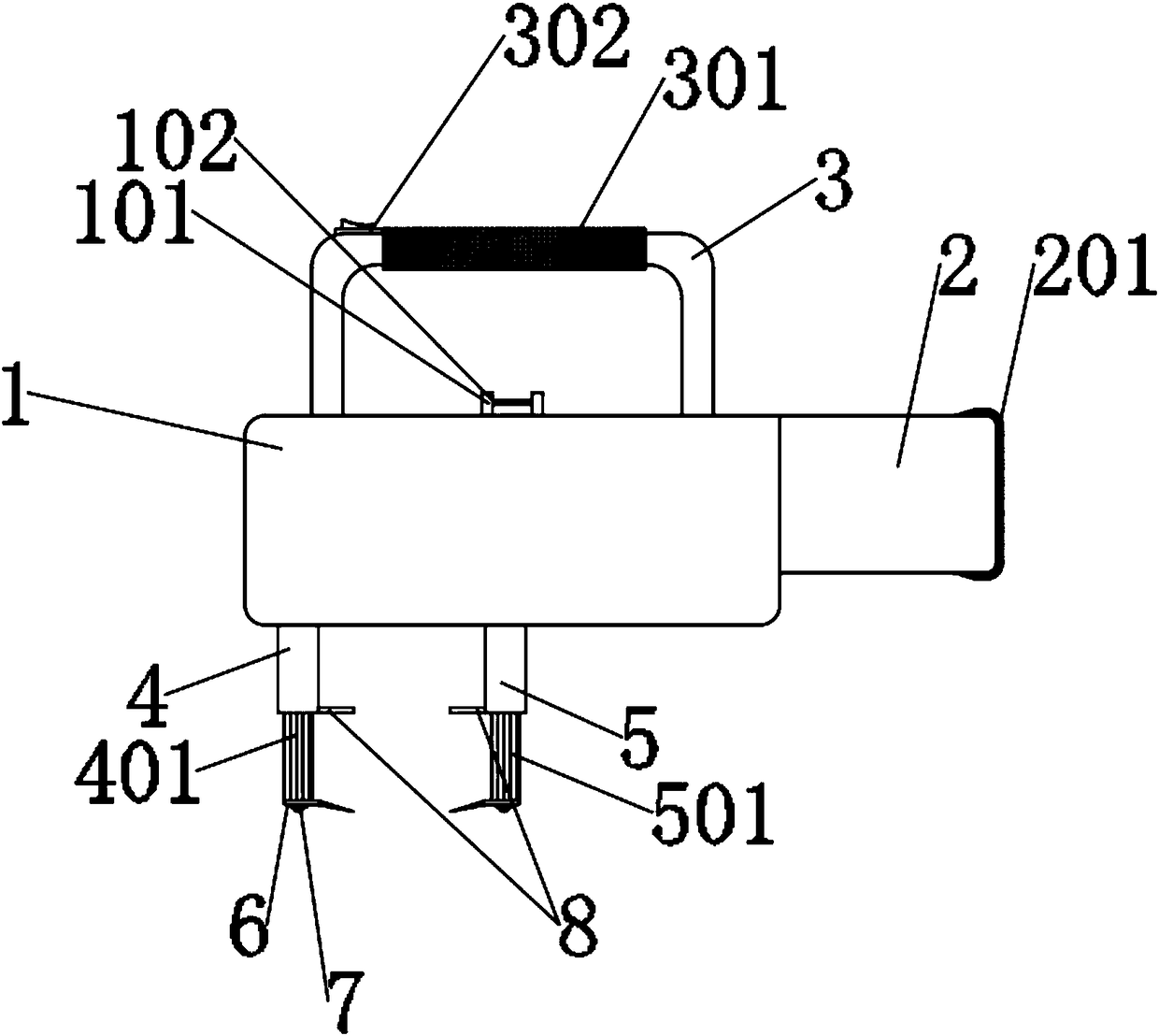

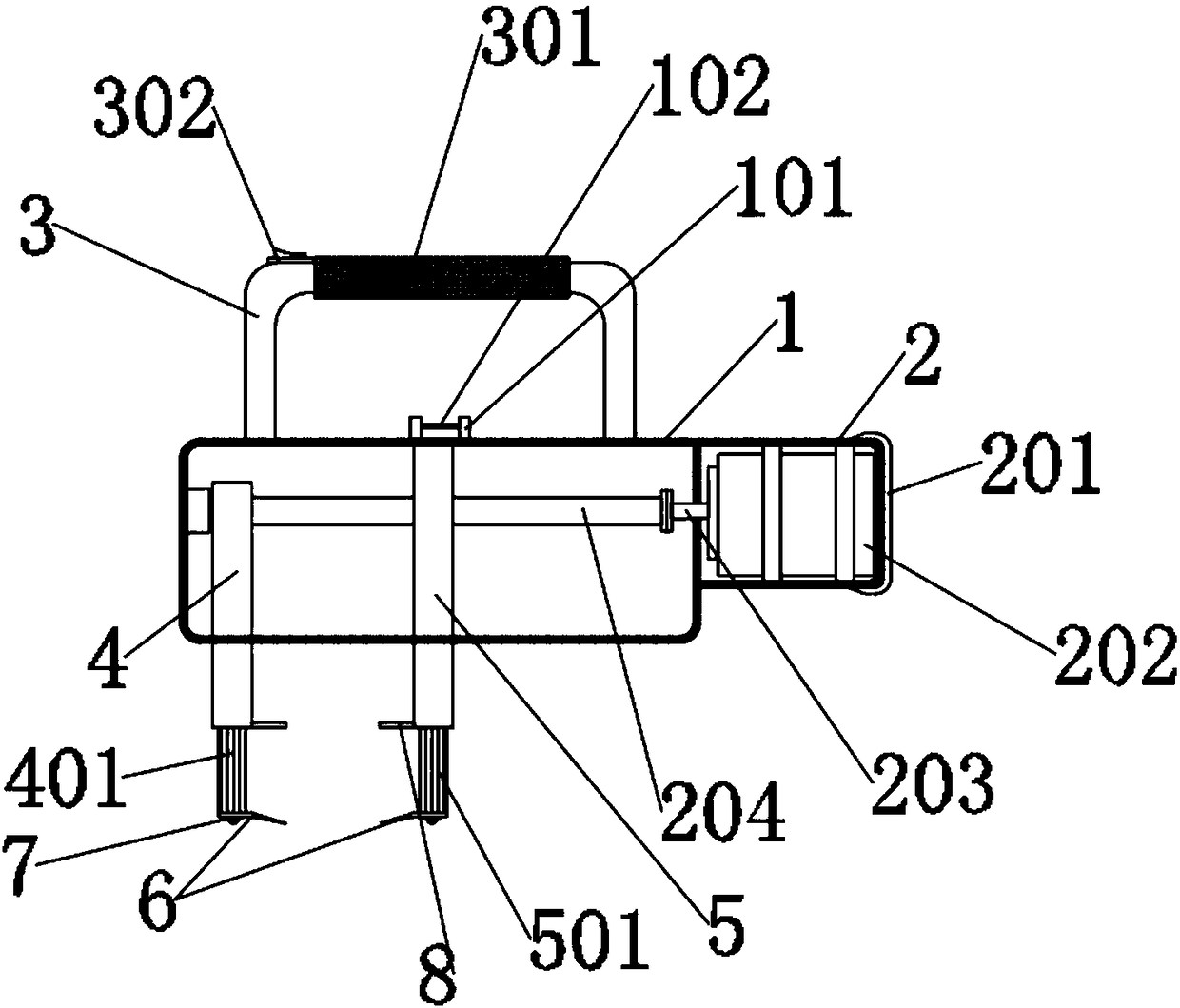

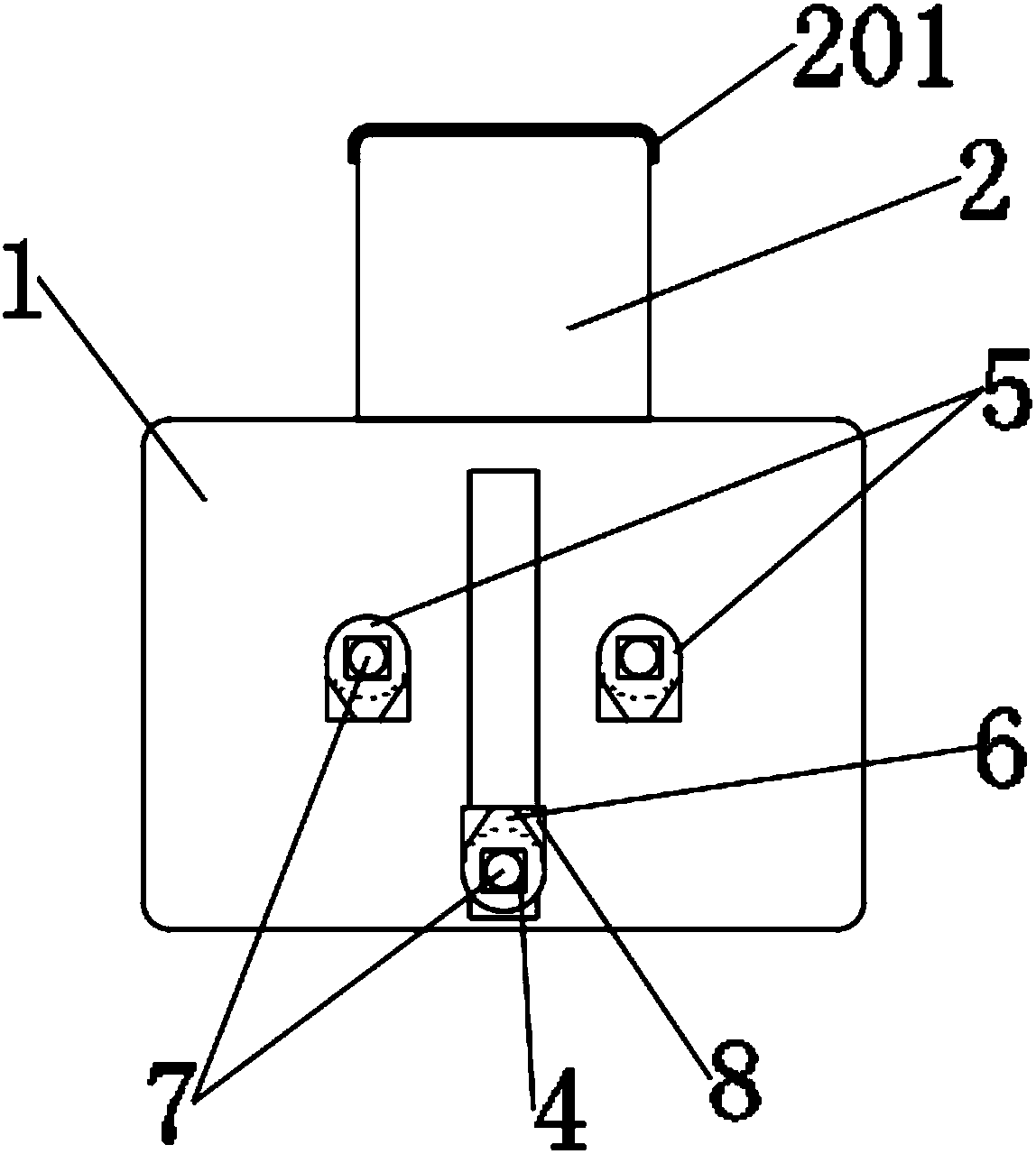

[0039] as attached figure 1 to attach Figure 12 Shown:

[0040]The present invention provides a plastic pipe bending machine, including a main body 1, a support block 101, a connecting rod 102, a motor compartment 2, a protective cover 201, a motor 202, a transmission shaft 203, a screw 204, a handpiece 3, a non-slip leather cover 301, a switch 302, Movable upper part 4, movable lower part 401, first internal telescopic rod 402, fixed upper part 5, fixed lower part 501, second internal telescopic rod 502, rotating rod 503, transmission part 504, rotating part 505, transmission belt 506, starting Pipe fitting 6, universal ball 7 and stopper 8; the main body 1 is a hollow rectangular structure, and the side of the main body 1 is installed with a motor compartment 2 by welding; the side of the motor compartment 2 is bonded The protective cover 201 is installed in the way, and the motor 202 is installed inside the motor compartment 2; the motor 2 is connected with the screw rod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap