Tablecloth steam hot-pressing and cutting device and processing method implemented by same

A cutting device and steam technology, applied in washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc., can solve the problems of excessive cutting impurities, product damage, low operating efficiency, etc., to improve cleanliness and aesthetics, The effect of speeding up the work process and reducing the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

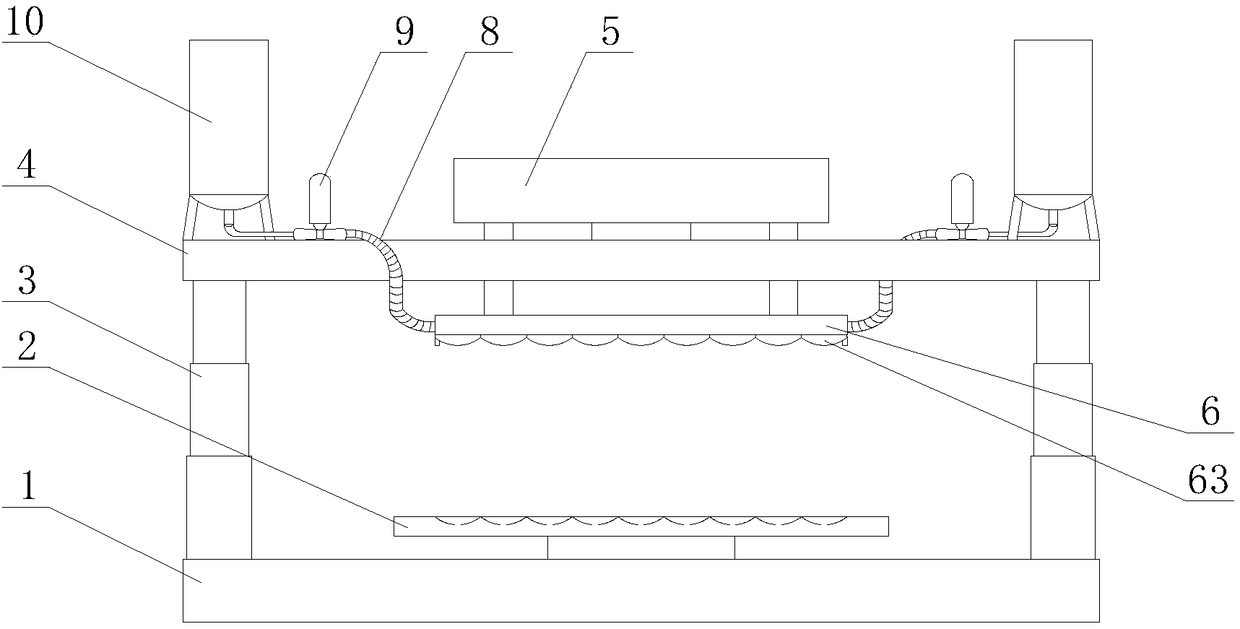

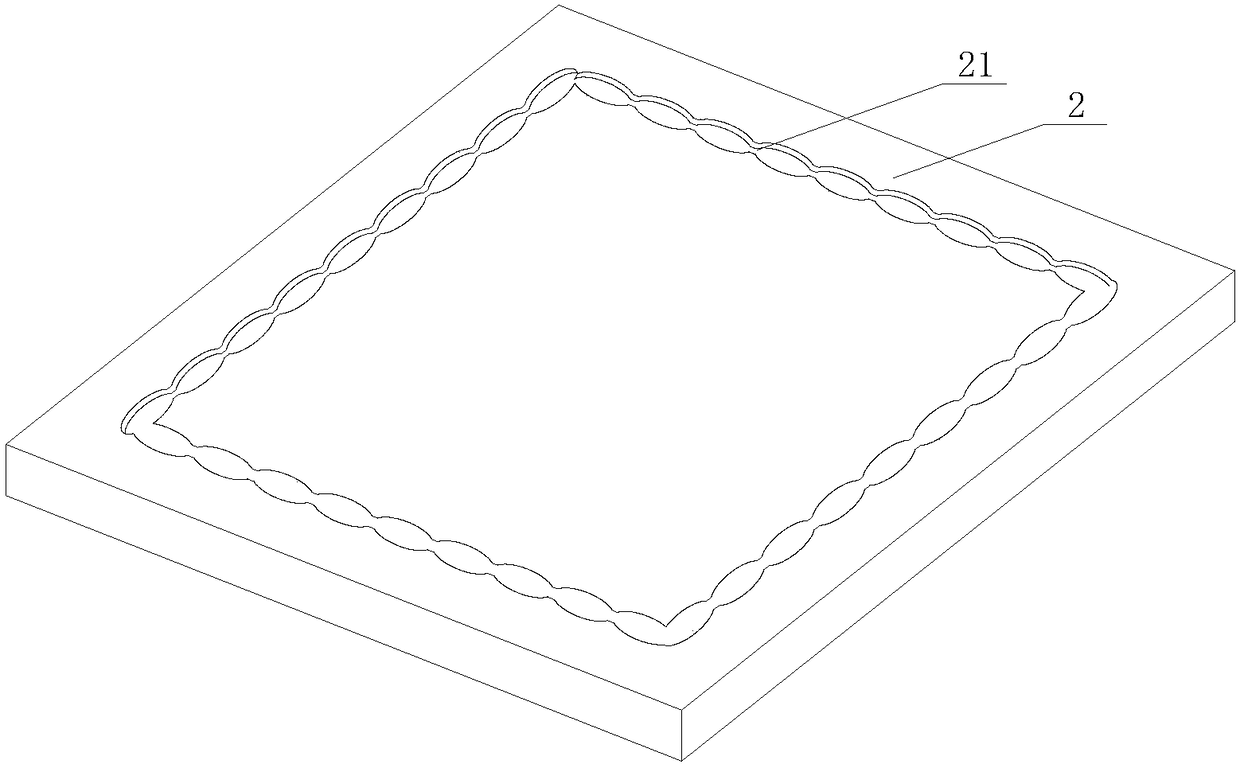

[0027] from Figure 1-4 It can be seen that a tablecloth steam hot-press cutting device in this embodiment includes a base 1, a cutting table 2 is fixedly installed on the upper surface of the base 1, and an arc groove 21 is opened on the upper surface of the cutting table 2. The inside of the groove 21 has no edges and corners, is easy to take care of, and has a low residue after treatment. The cutting table 2 is horizontally installed at the center of the upper surface of the base 1. The upper surface of the base 1 is also provided with guide posts 3 at intervals. The bottom of the guide posts 3 Fixedly welded with the base 1, the top of the guide post 3 is provided with a frame 4, and the frame 4 tends to be stationary under the action of the base 1 and the guide post 3.

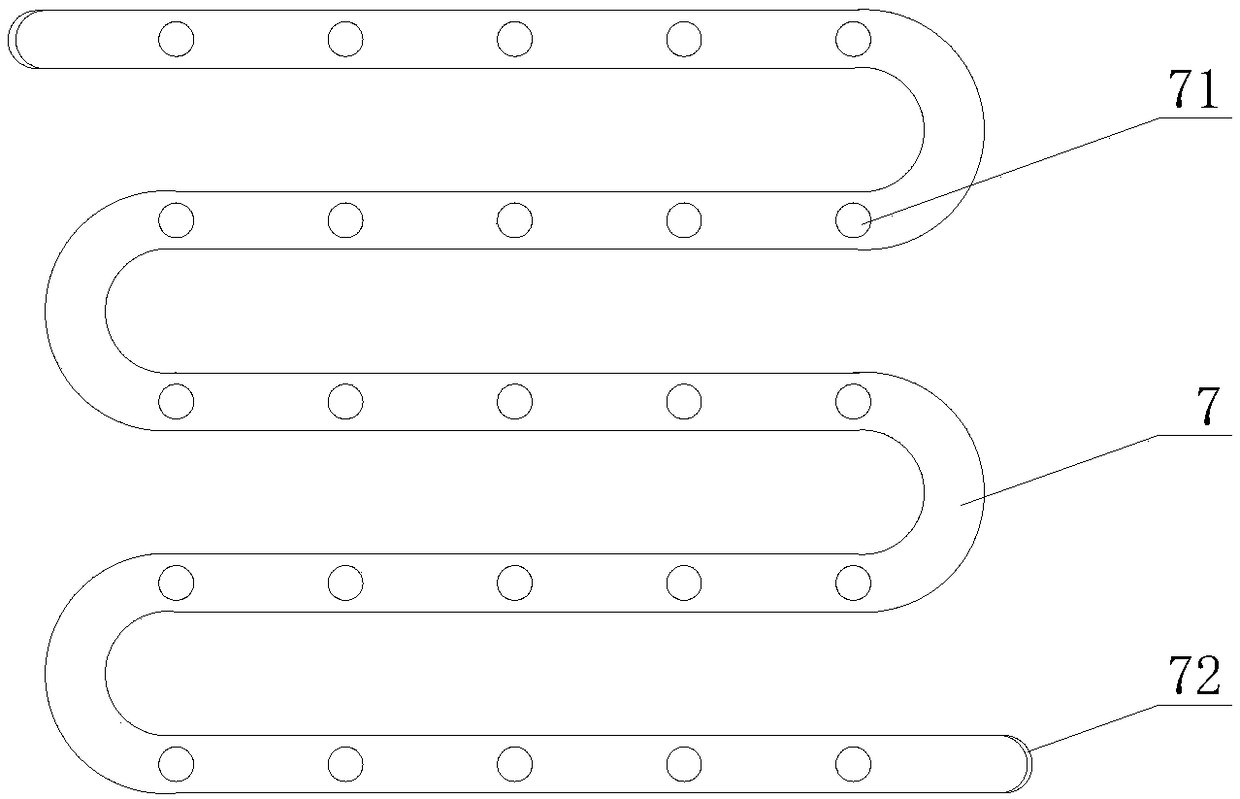

[0028] The upper surface of the frame 4 is fixedly equipped with a hydraulic telescopic cylinder 5, the output end of the hydraulic telescopic cylinder 5 runs through the frame 4 and is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com