Amplitude separation and reverse support replacement construction method for open-excavated single-layer twin-bore or multi-bore tunnel

A construction method and single-layer technology, applied in excavation, artificial islands, water conservancy projects, etc., can solve problems such as insufficient construction sites, achieve the effects of saving construction time and cost, reasonable force conversion, and optimized support replacement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

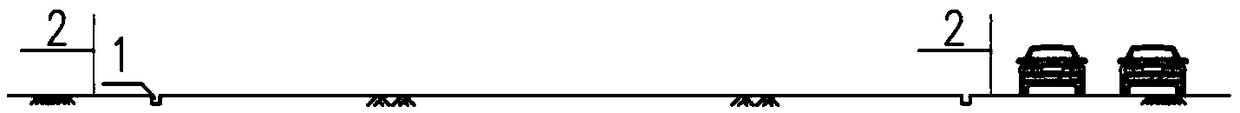

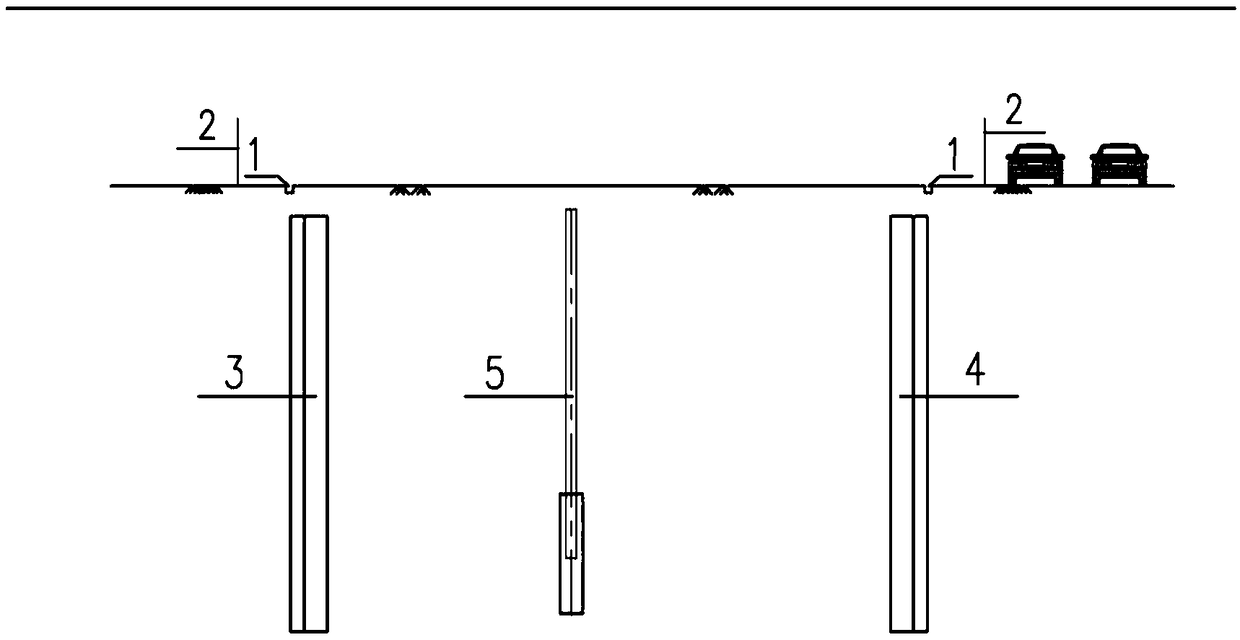

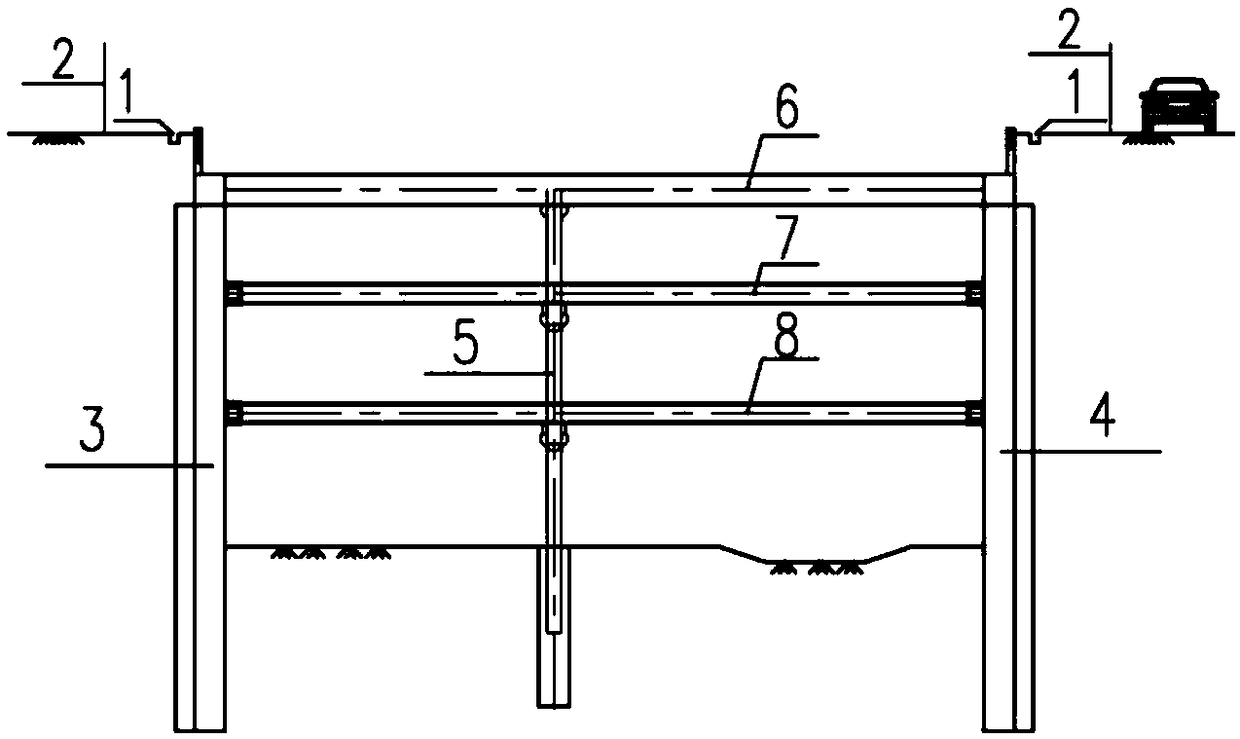

[0043] Embodiments of the present invention can be found in Figure 1 to Figure 14 shown.

[0044] The invention aims at double (multiple) hole single-layer underground road structure, and adopts open-cut and sequential construction method to construct underground road, and the structure does not carry out framing, and is constructed in stages, saving site space and engineering cost. Taking the double-hole structure as an example, the construction method and process arrangement are explained.

[0045] It can be seen from the figure that when excavating the side foundation pit of the rear excavation, the supporting structure of the middle row is "reversely" replaced from top to bottom, so that the water and soil pressure of the side wall of the rear excavation can be safely transmitted to the middle wall and the oblique throw At the support, the support structure of the middle row shall be demolished after it is safely unloaded. In each process, the foundation pit support sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com