Rotary-type bulletproof helmet and bulletproof suit

A ballistic helmet and rotating technology, which is applied in protective equipment, personnel protection equipment, offensive equipment, etc., can solve the problems that the bulletproof ability is limited by the material, the bulletproof ability of the bulletproof helmet is limited by the material, and the bulletproof effect is not ideal, so as to improve the bulletproof effect Effect, the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

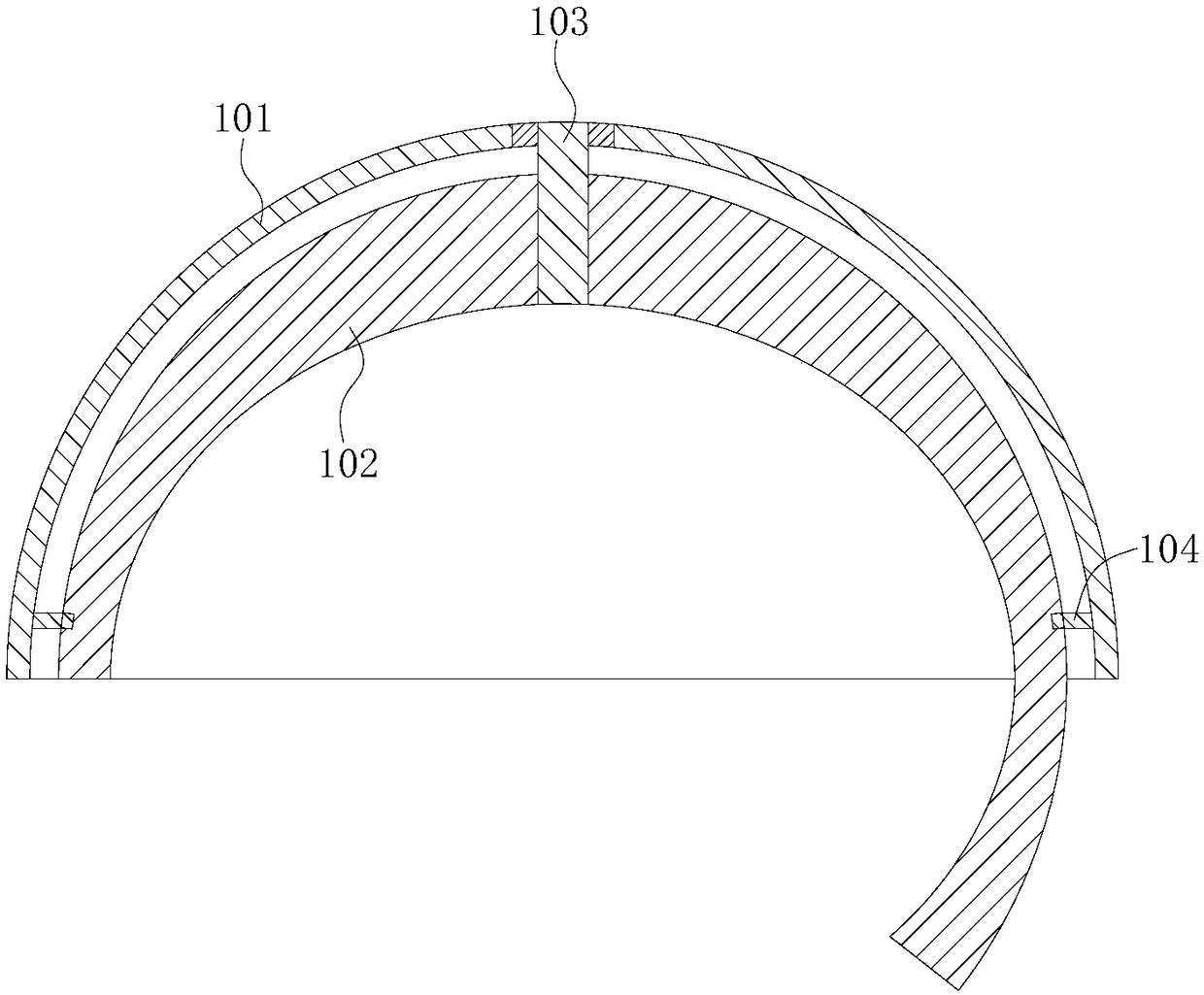

[0052] refer to Figure 1 to Figure 5 , the present embodiment provides a rotary ballistic helmet, comprising an inner liner 102, an outer shell 101 and a connecting portion 103, the top of the inner liner 102 is provided with a first through hole 107, and the top of the outer shell 101 is provided with a second through hole 111, The shell 101 is sleeved outside the inner liner 102, the connecting part 103 includes a first rotating part 112 and a second rotating part 113, the first rotating part 112 and the second rotating part 113 are connected in rotation, and the first rotating part 112 is clipped to the first rotating part 113. Through hole 107 , the second rotating portion 113 is engaged with the second rotating portion 113 .

[0053] The rotating bullet-proof helmet provided by this embodiment, under the premise of not changing the current production material and its pattern and thickness, designs a new structure, so that the inner liner 102 and the outer shell 101 becom...

Embodiment 2

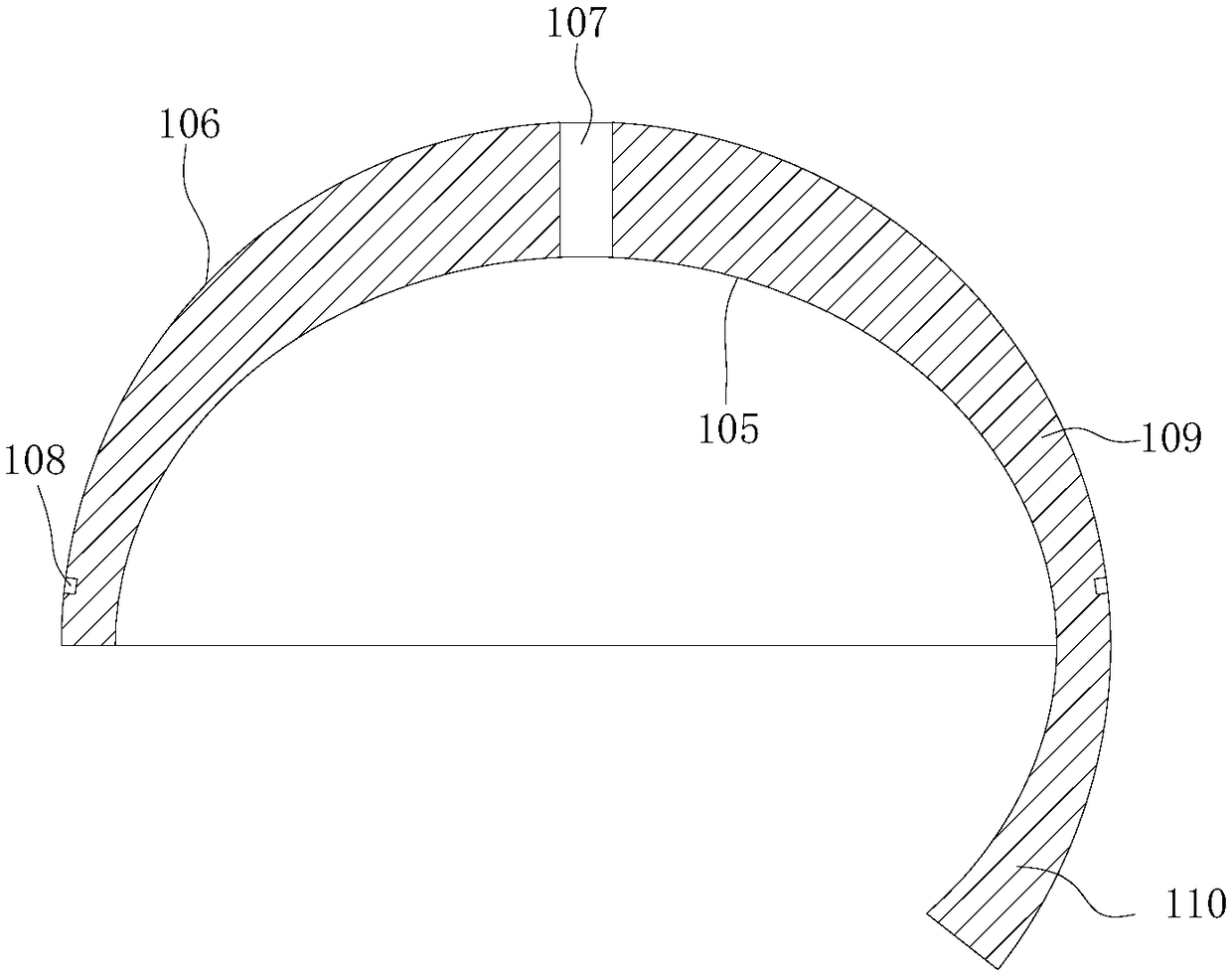

[0060] refer to Figure 6 , this embodiment also provides a rotary bulletproof helmet, this embodiment is a further improvement on the basis of the technical solution in embodiment 1, the technical solution described in embodiment 1 is also applicable to this embodiment, embodiment 1 has been The disclosed technical solutions will not be described repeatedly.

[0061] Specifically, the difference between this embodiment and Embodiment 1 is that the inner liner 102 of the rotating bulletproof helmet provided by this embodiment includes a head protection device 109 and a neck protection device 110, and the outer shell 101 is wrapped around the head protection device 109 at the same time. and a neck protector 110 .

[0062] In this embodiment, the outer shell 101 completely encloses the inner liner 102 .

Embodiment 3

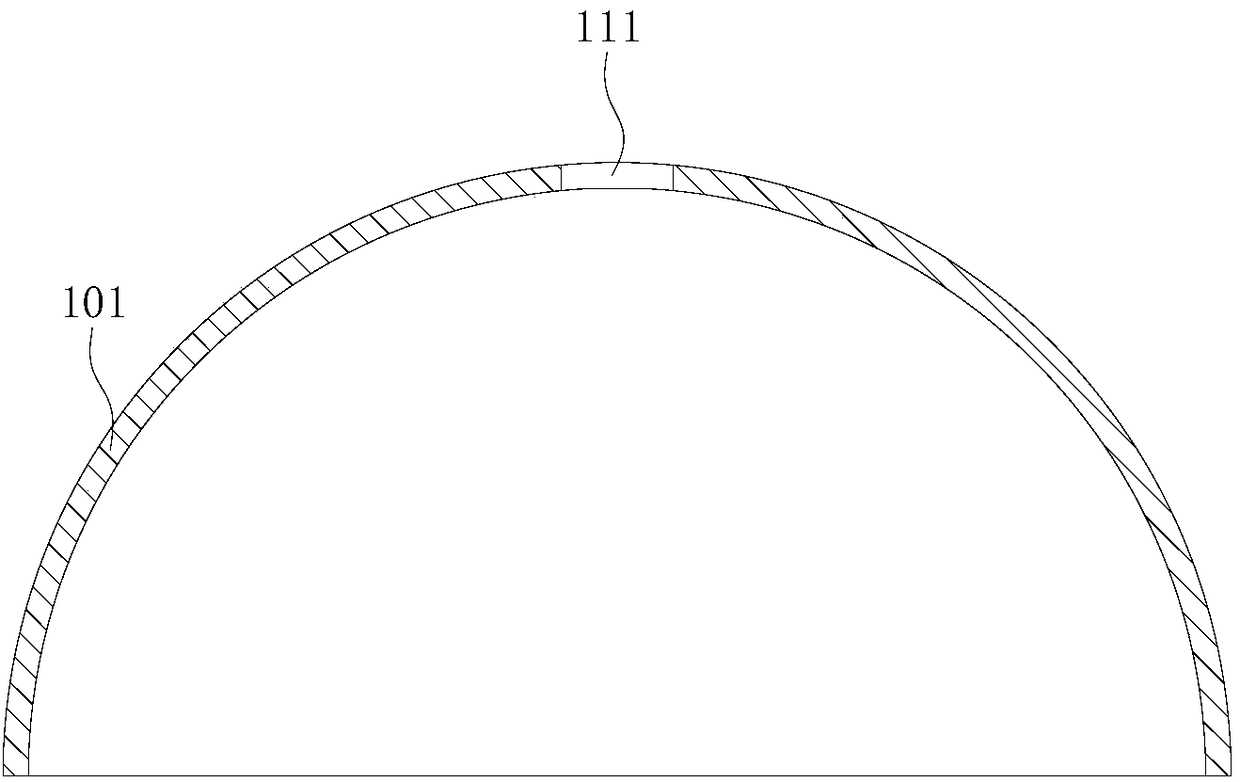

[0064] refer to Figure 7 and Figure 8 , this embodiment also provides a rotary bulletproof helmet, this embodiment is a further improvement on the basis of the technical solution in embodiment 1, the technical solution described in embodiment 1 is also applicable to this embodiment, embodiment 1 has been The disclosed technical solutions will not be described repeatedly.

[0065] Specifically, the difference between this embodiment and Embodiment 1 is that the rotating bulletproof helmet provided by this embodiment further includes a supporting device 116 installed between the inner liner 102 and the outer shell 101 . The supporting device 116 can cooperate with the connecting part 103 to make the rotation between the outer shell 101 and the inner liner 102 more stable, so that the rotating bulletproof helmet has a more stable bulletproof effect.

[0066] The supporting device 116 includes a first rotating ring 117 and a second rotating ring 118, the first rotating ring 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com