Sensor and monitoring system using the sensor

A monitoring system and sensor technology, used in instruments, alarms, anti-theft alarms, etc., can solve problems such as affecting the use of sensors, affecting the appearance, and sensor failure, and achieving the effect of eliminating wiring and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

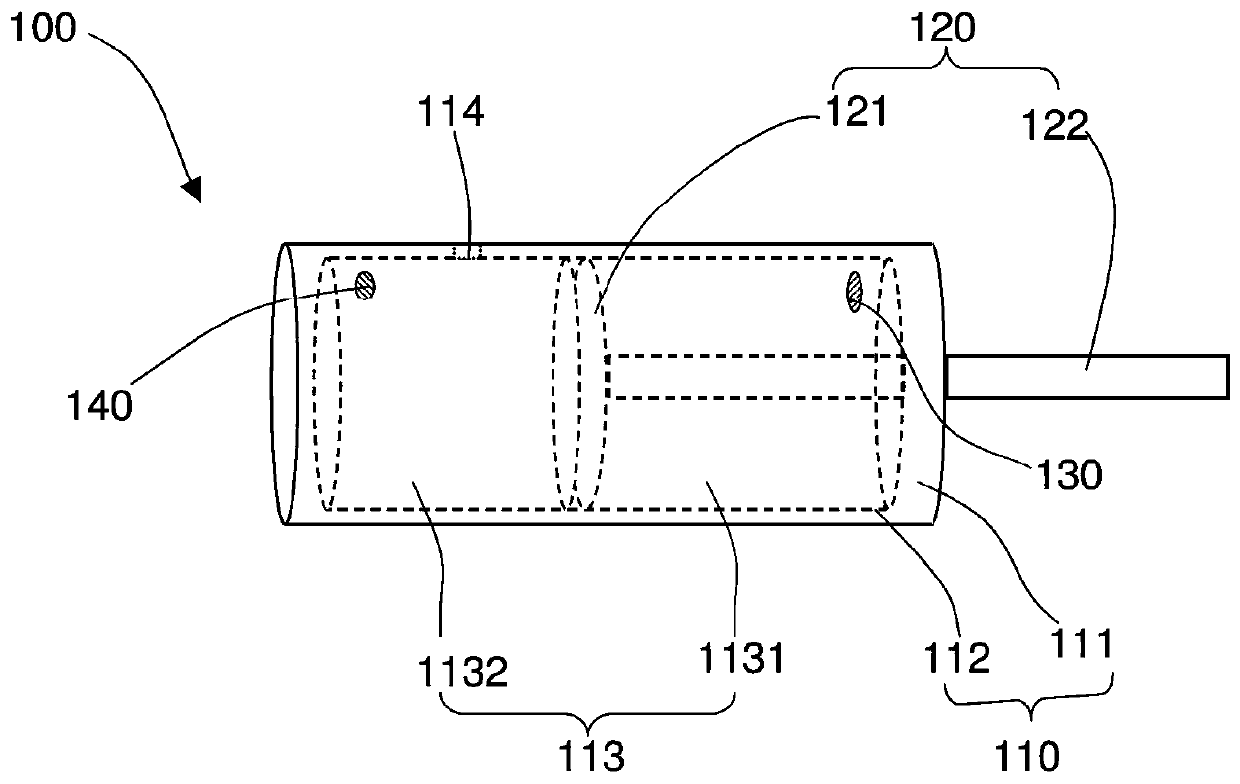

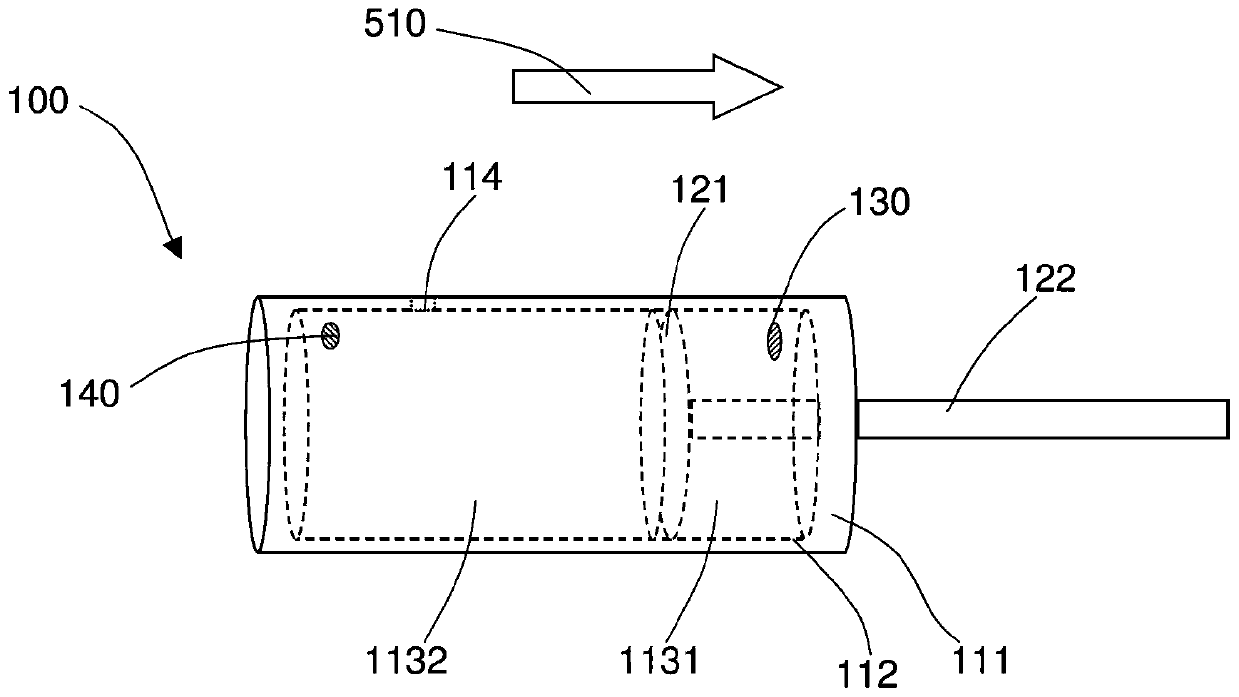

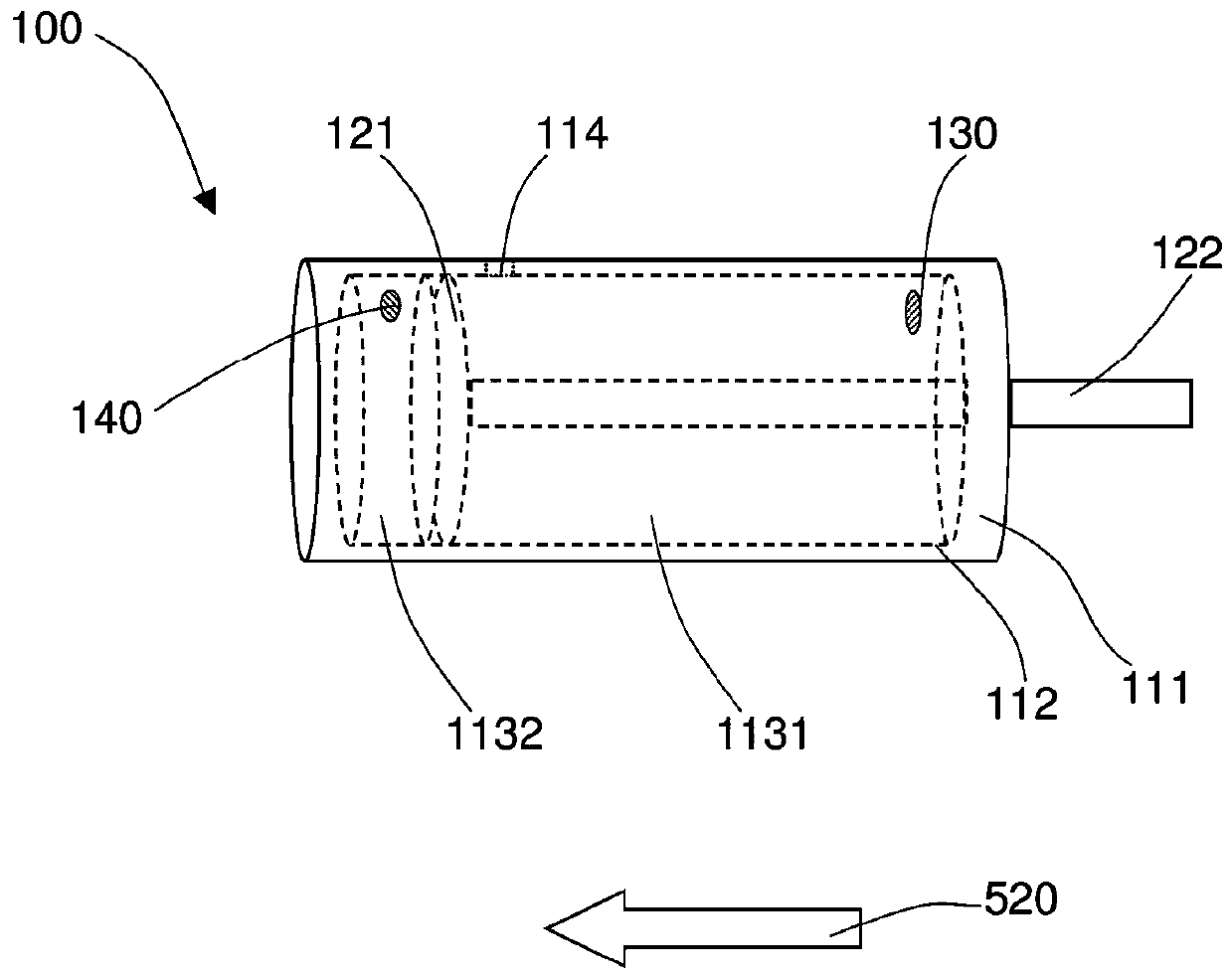

[0062] figure 1Shown is a schematic structural diagram of a sensor 100 according to an embodiment of the present invention. In the figure, the sensor 100 includes an air valve 110, a first sounding device 130 and a second sounding device 140 respectively arranged at both ends of the air valve 110, and a piston 120 slidably installed inside the air valve 110. The air valve 110 includes a housing 111 and a cavity 112 formed in the casing 111, the casing 111 is roughly in the shape of a hollow cylinder, the inner side wall of the cavity 112 is roughly a smooth arc surface, and the surface of the casing 111 is provided with a vent hole 114 connected to the cavity 112; The piston 120 includes a plug body 121 and a push rod 122 extending from one side of the plug body 121. The plug body 121 is slidably connected to the inner wall of the cavity 112 to form an air chamber 113, and divides the air chamber 113 into a first air chamber 1131. and the second air chamber 1132, the push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com