Double-channel filter capable of automatically closing assembly port during replacement

It is a technology of automatic closing and assembly port, which is used in fixed filter element filters, filtration separation, and filtration processing. The effect of preventing switch misoperation and easy installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

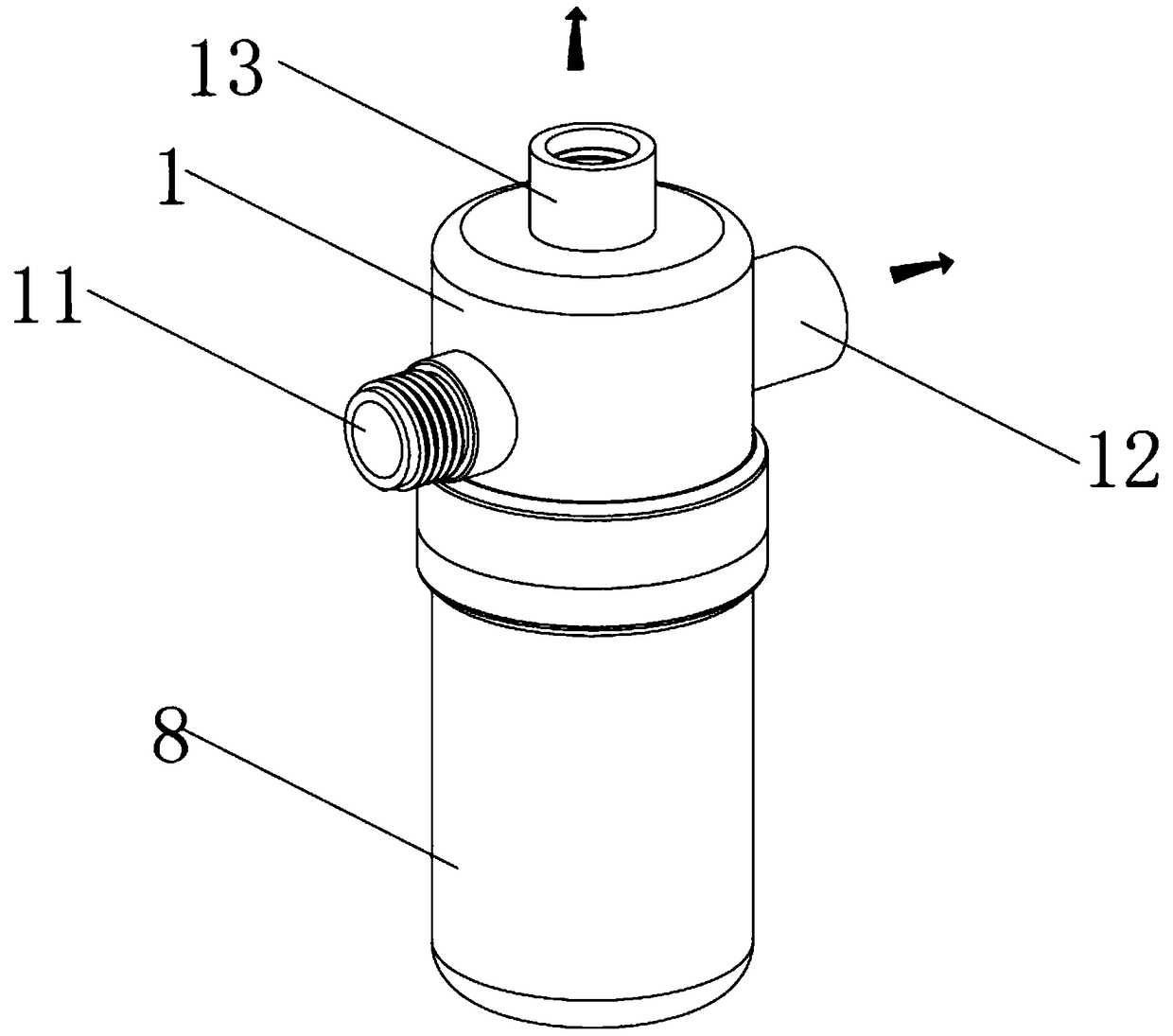

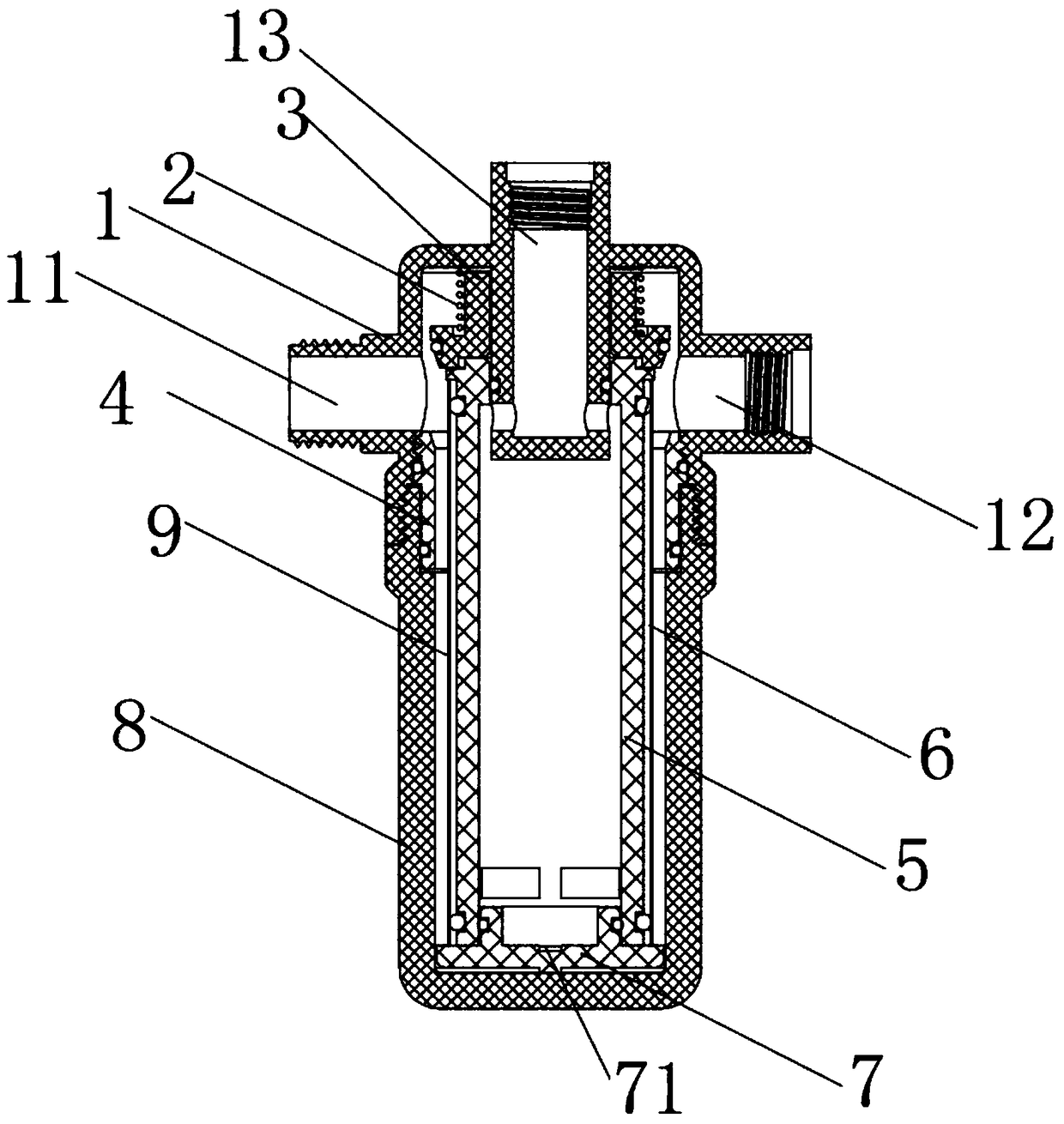

[0036] Such as Figures 1 to 6 As shown, the double-channel filter that can automatically close the assembly port when it is replaced, including the filter body,

[0037] The filter body is composed of an upper cover assembly and a tank assembly;

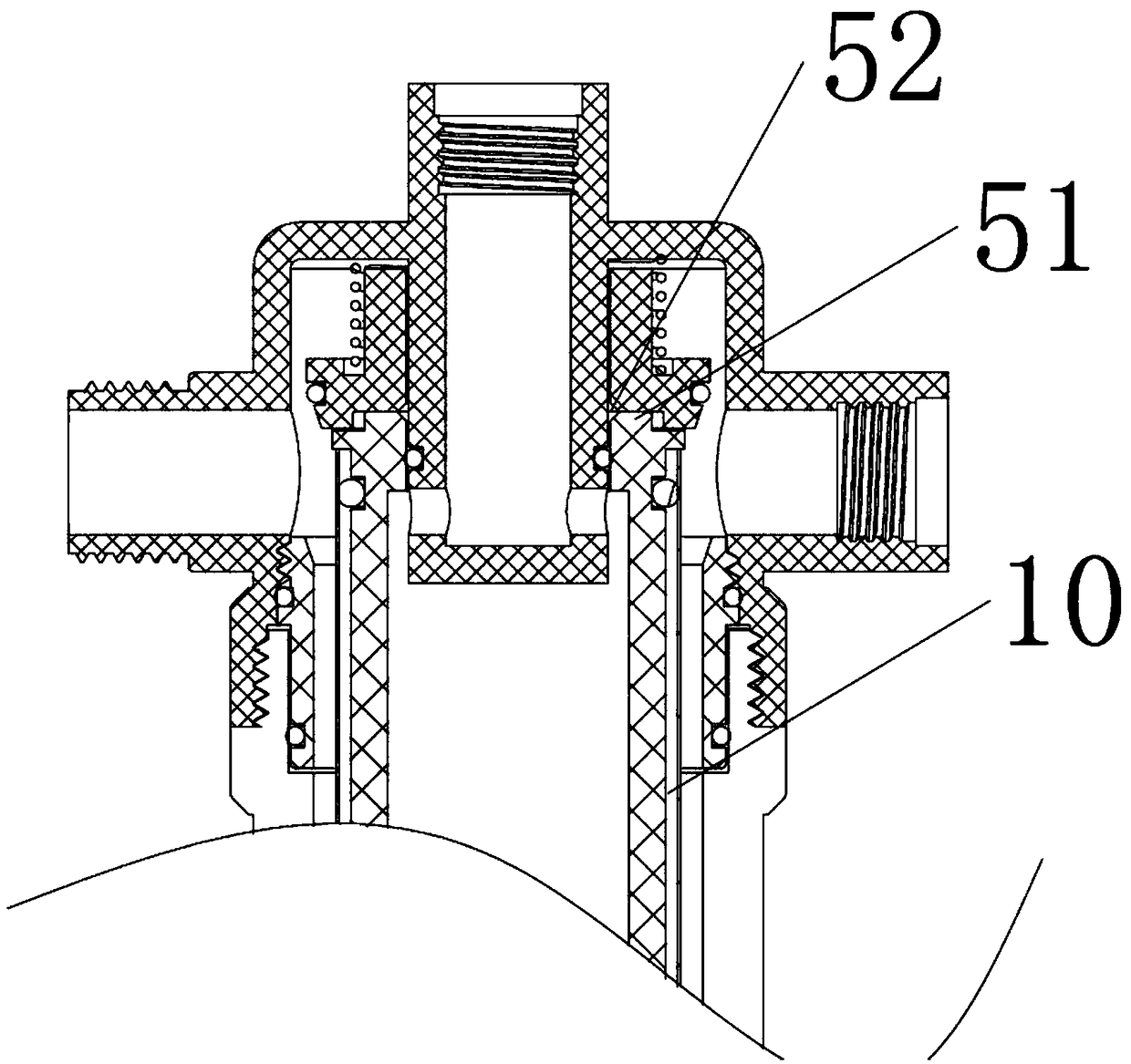

[0038] The upper cover assembly includes an upper cover and an automatic closing mechanism located inside it. The upper cover 1 is provided with a raw water inlet channel 11, a raw water outlet channel 12, a purified water outlet channel 13 and an assembly port 14. The raw water inlet channel 11 and The raw water outlet channel 12 is connected, and the water inlet end of the purified water outlet channel 13 is provided with several water inlet holes 15 in the circumferential direction;

[0039] The automatic closing mechanism includes an elastic reset member 2 and a sealing structure, the elastic reset member 2 and the sealing structure are sleeved outside the purified water outlet channel 13, the elastic reset member 2 and the sea...

Embodiment 2

[0049] The basic structure is the same as in Example 1, the difference is that the filter skeleton 5 is a circumferentially closed anti-scaling filter material bottle, and the filter screen 6 is sleeved outside the scale-inhibiting filter material bottle, and the interval between the two forms Purified water chamber 10, the bottom of the anti-scaling filter material bottle is provided with a filter bottle cover 7 with several hole passages 71, and the filter bottle cover 7 is detachably connected with the anti-scaling filter material bottle, such as screw connection or card connection. The hole channel 71 communicates with the purified water cavity 10 and the inner cavity of the filter skeleton 5 . This embodiment adopts the design of filter net 6+closed anti-scaling filter material bottle body, so that the raw water can be preliminarily filtered, and then enter the inner cavity through the bottom of the anti-scaling filter material bottle body, so that the scale-inhibiting fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com