End filter capable of automatically closing water inlet and water outlet during maintenance and replacement

An automatic sealing, maintenance and replacement technology, applied in membrane filters, fixed filter element filters, filtration and separation, etc., can solve problems such as failure to automatically seal the water inlet and outlet, hot water pipe damage, and lasing water injuring people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

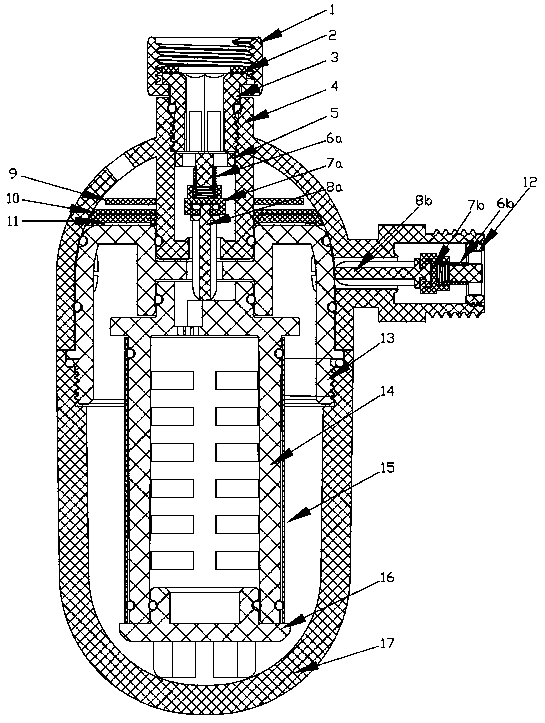

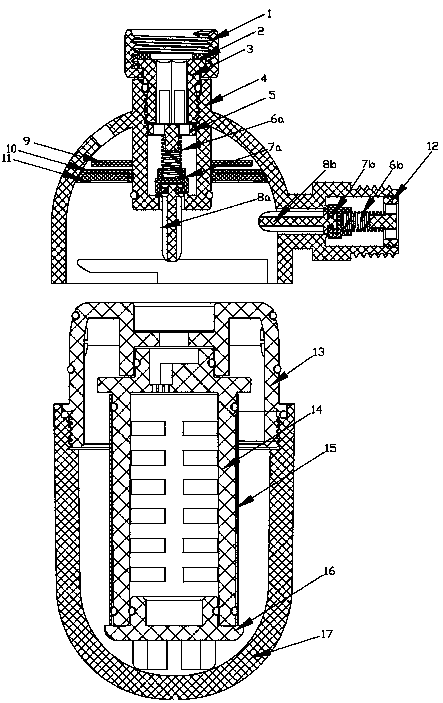

[0031] The end filter that can automatically close the water inlet and outlet channels during maintenance and replacement includes the filter bottle body, which is composed of an upper cover assembly and a tank body assembly;

[0032] The upper cover assembly includes a upper cover 4, the upper cover 4 is provided with a water inlet channel and a water outlet channel, a first connector 3 is arranged in the water outlet channel, and a second connector 1 is arranged at the outer end of the first connector 3;

[0033] The tank assembly includes an inner cover 13, a tank body 17 and a filter mechanism coaxially arranged in the tank body 17. The inner cover 13 is correspondingly provided with a water inlet hole and a water outlet hole that can communicate with the water inlet channel and the water outlet channel. The inner cover 13 is detachably connected to the tank body 17, such as any one of screw connection and snap connection, and at least one sealing member is provided in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com