Tail end filter with rapidly dismounted and replaced scale inhibition filter element component

A core component and filter technology, which is applied in the fields of filtration treatment, descaling and water softening, chemical instruments and methods, etc., can solve the problems of limited filtration effect, injury of lasing water, injury of hot water pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

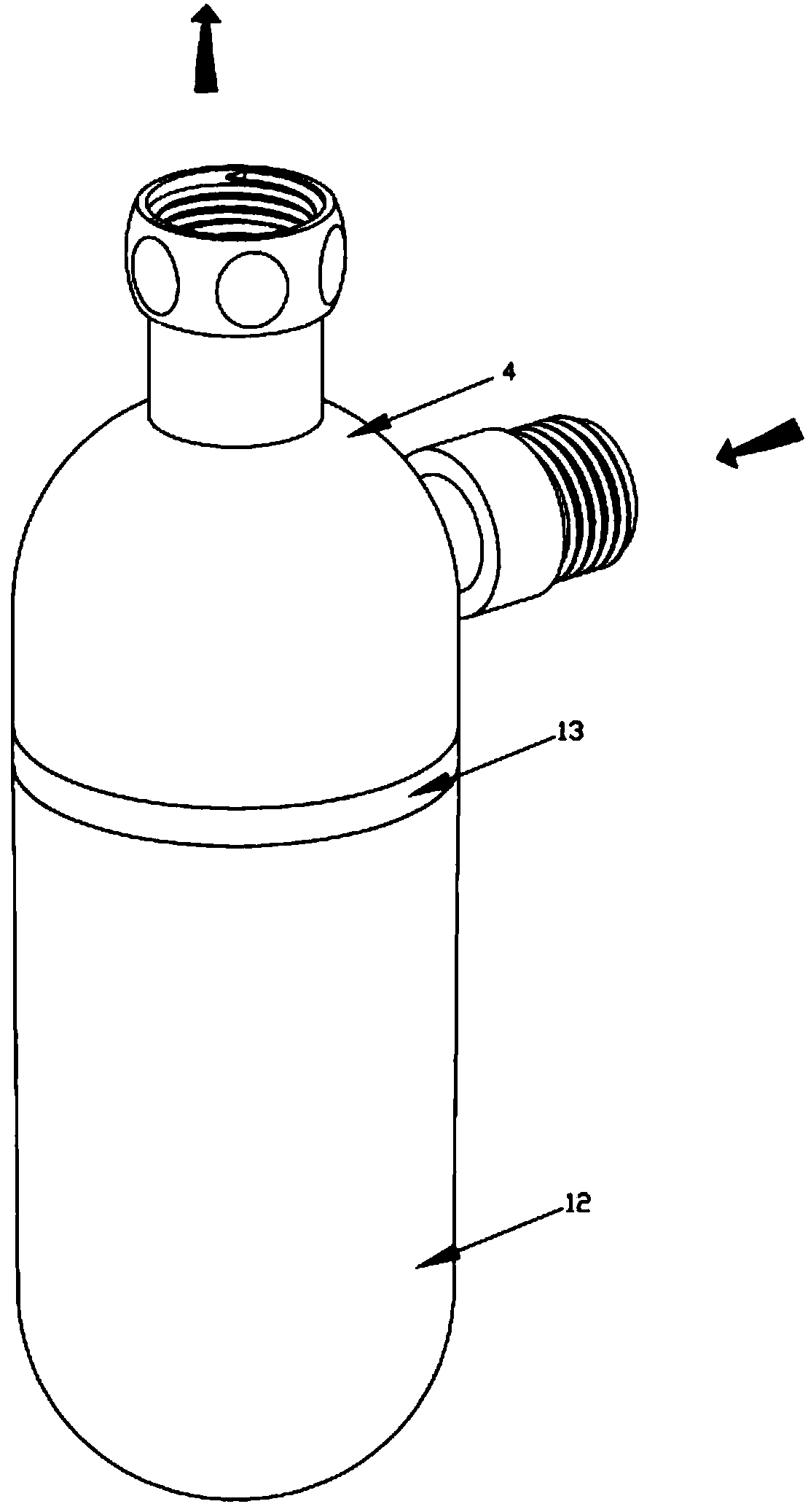

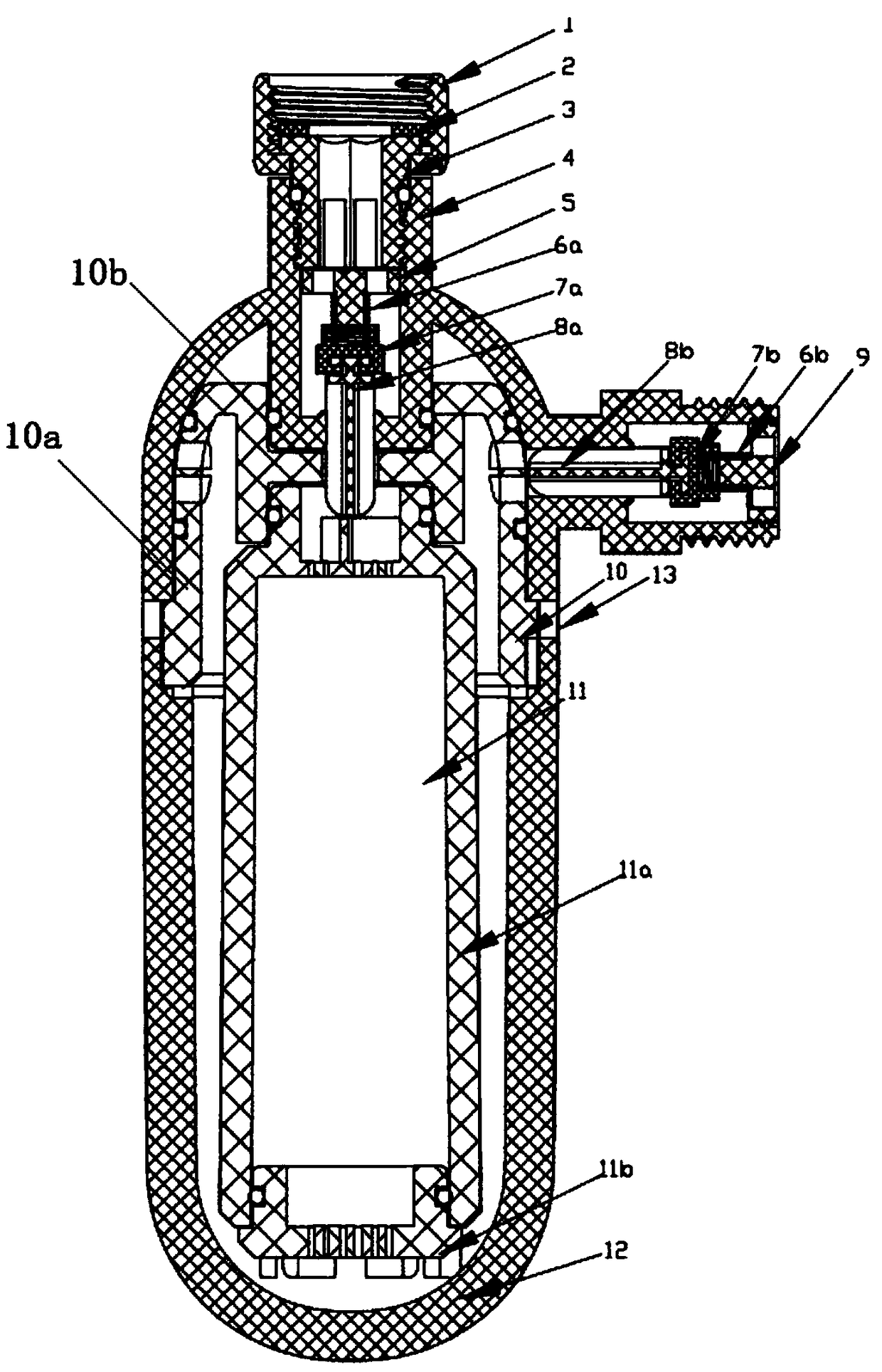

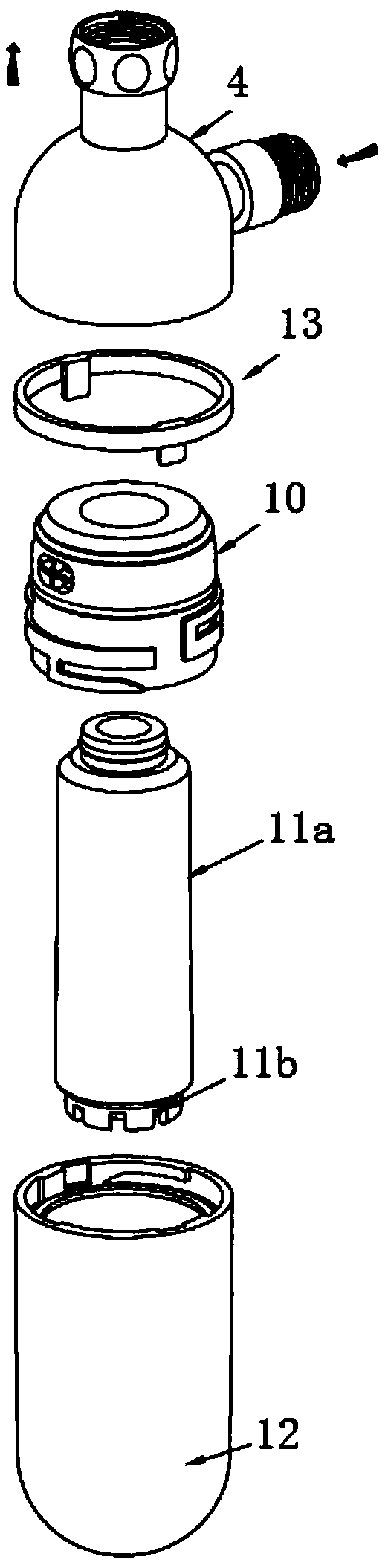

[0034] The end filter of the anti-scaling filter core assembly can be quickly replaced, including the filter bottle body, which is composed of an upper cover assembly and a tank assembly;

[0035] The upper cover assembly includes a upper cover 4, the upper cover 4 is provided with a water inlet channel and a water outlet channel, a first connector 3 is arranged in the water outlet channel, and a second connector 1 is arranged at the outer end of the first connector 3;

[0036] The tank assembly includes an inner cover 10, a tank body 12 and an anti-scaling filter core assembly 11 coaxially arranged in the tank body 12. The inner cover 10 is correspondingly provided with a water inlet and a The water outlet hole, the inner cover 10 is detachably connected to the tank body 12, and at least one sealing member is provided in the circumferential direction between the top end of the anti-scaling filter element assembly 11 and the inner cover 10;

[0037] The anti-scaling filter mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com