A kind of preparation method of high entropy alloy reinforced aluminum matrix composite material

A high-entropy alloy and composite material technology, applied in the field of high-entropy alloy reinforced aluminum alloy composite materials and its preparation, can solve problems such as room temperature brittleness and processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of composite powder: FeNiCoCrCuAl prepared according to the above table 2.8 (The subscript is the molar ratio) The powder was mechanically alloyed in a high-energy ball mill with a dry milling speed of 350r / min. After 40 hours of dry milling, the wet milling time was 5 hours at a wet milling speed of 300r / min. A body-centered cubic structure was obtained. Entropy Alloy FeNiCoCrCuAl 2.8 powder. Specific steps are as follows:

[0031] a) Put the powder waiting for ball milling into a stainless steel grinding tank, use stainless steel balls as the grinding body, and ball mill according to the ball powder mass ratio of not less than 10:1. Before ball milling, use a vacuum machine to evacuate for 10 minutes, and then fill it with 0.5MPa argon as a protective gas; the speed of the ball mill is 350r / min, and the rotation direction needs to be adjusted once every 60 minutes.

[0032] b) Add absolute ethanol to the powder milled for 45 hours for 5 hours of wet...

Embodiment 2

[0037] Composite powder preparation: prepare TiFeNiCoCrCuAl according to the above table 1 2 (The subscript is the molar ratio). The high-entropy alloy powder was prepared. For specific steps, refer to Example 1.

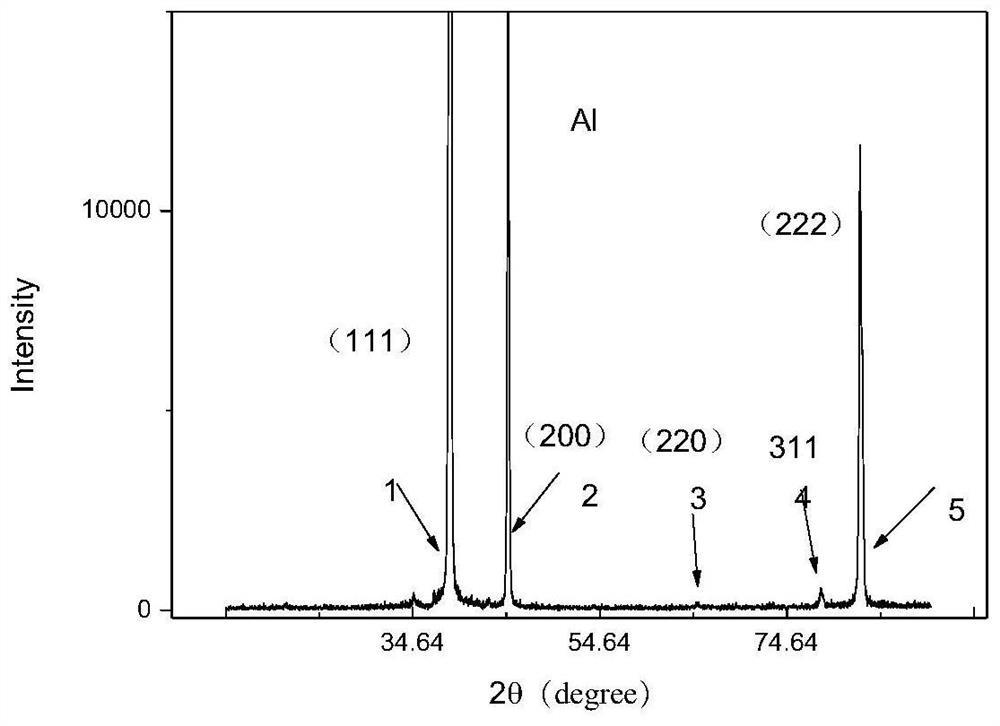

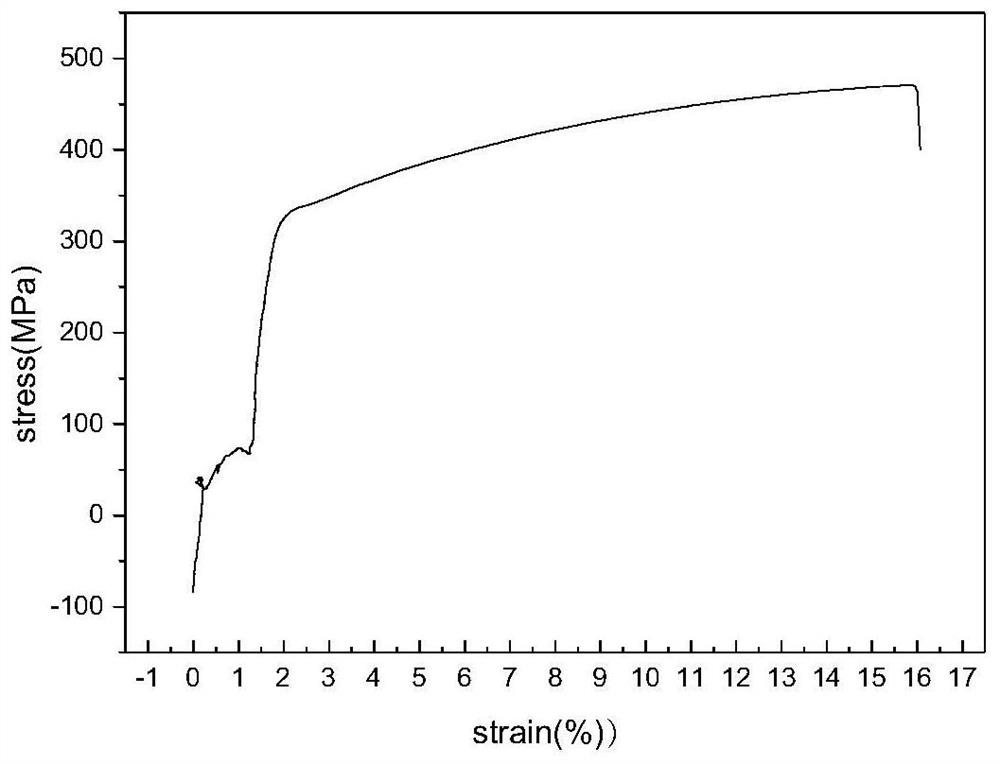

[0038] The alloy matrix of the composite material is selected from 7075 aluminum alloy, and the preparation process of the composite material refers to Example 1. Composite physical map and XRD analysis see Figure 4 with Figure 5 . XRD analysis shows that both the aluminum alloy and the high-entropy alloy maintain their respective crystallographic structures ( Figure 5 ). The compressive yield strength, fracture strength and plastic strain of the composite material reached 354.5251 Mpa, 469.7032 MPa and 16.165%, respectively.

Embodiment 3

[0040] Composite powder preparation: according to the prepared Ti in Table 1 1.5 FeNiCoCrCuAl (the subscript is the molar ratio) was used to prepare high-entropy alloy powder, and the specific steps refer to Example 1.

[0041]The alloy matrix of the composite material is selected from 7075 aluminum alloy, and the preparation process of the composite material refers to Example 1.

[0042] The high-entropy alloy reinforced aluminum-based composite material of the present invention uses high-entropy alloy particles as a reinforcing phase. The first is to design a high-strength and high-hardness high-entropy alloy system according to the design principles of high-entropy alloys; to proportion alloys according to the design components, and to adopt mechanical alloying technology and vacuum ball milling to produce high-entropy alloy powders with a body-centered cubic structure; The prepared high-entropy alloy powder is fully mechanically mixed with the selected aluminum alloy powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com