Test device capable of determining shaft component anti-seize performance and application thereof

A test device and a technology for shaft parts, applied in the direction of mechanical bearing testing, etc., can solve the problem of difficulty in simulating the motion state and bearing form of shaft parts, and achieve the effect of accurate motion state and bearing form, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

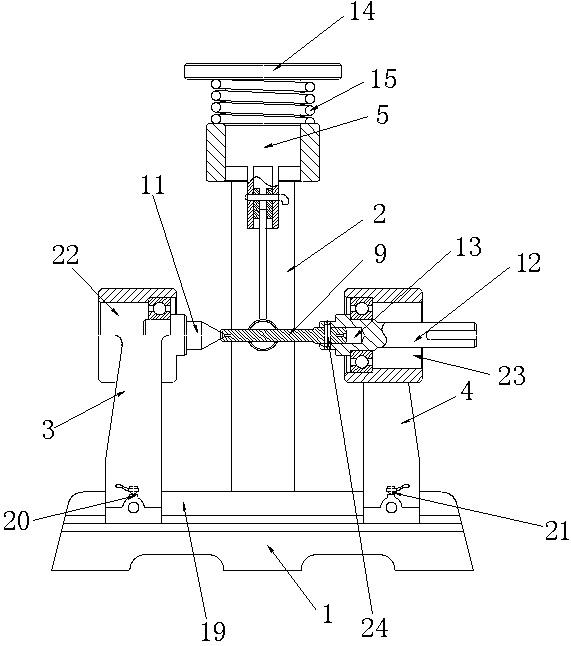

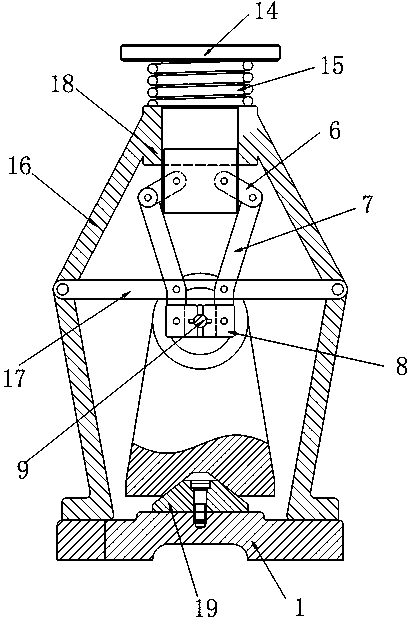

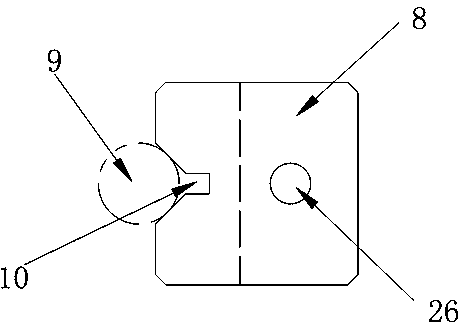

[0032] Such as figure 1 and figure 2 The test device that can measure the anti-jamming performance of shaft parts includes a workbench 1, a loading bracket 2 with a detachable bottom end installed on the workbench 1, which is set on the workbench 1 and forms a horizontal movement with the workbench 1. The first movable frame 3 and the second movable frame 4 of the pair and the loading piston 5 that are arranged on the top of the loading bracket 2 and the loading bracket 2 constitute a vertical movement pair, the first movable frame 3 and the second movable The racks 4 all slide along the direction perpendicular to the loading bracket 2 .

[0033] In the present application, two left and right connecting rods 6 are symmetrically rotated through a living hinge on both sides of the lower part of the loading piston 5, and one end of the two connecting rods 6 away from the loading piston 5 is respectively rotated through a living hinge to be provided with a loading lever 7. The ...

Embodiment 2

[0041] This embodiment is a method for measuring the seizure resistance of the test shaft using the test device described in Embodiment 1. The method of this embodiment specifically includes the following steps:

[0042] Step 1, move the first movable frame 3 towards the direction away from the second movable frame 4, install one end of the test shaft 9 to be tested in the mounting hole 13 on the transmission shaft 12, and keep the test shaft 9 through the Pass between the two clamping blocks 8, move the first movable frame 3, make the top 11 withstand the end of the test shaft 9 away from the end of the second movable frame 4, and paste the pressure sensor on the surface of the test shaft 9;

[0043] Step 2, preload the loading piston 5 to make it move downward, and remove the preload after the clamp block 8 can stably hold the test shaft 9 .

[0044] Step 2.1, manually rotate the transmission shaft 12, use a dial indicator to measure the runout of the test shaft 9 for one ro...

Embodiment 3

[0051] The technical solution of this embodiment is a method for measuring the ultimate seizure resistance of test shafts. The implementation of this embodiment adopts the test device disclosed in Embodiment 1 that can measure the seizure resistance of shaft parts. The method described in this embodiment is specific. Include the following steps:

[0052] Step 1, move the first movable frame 3 towards the direction away from the second movable frame 4, install one end of the test shaft 9 to be tested in the mounting hole 13 on the transmission shaft 12, and keep the test shaft 9 through the Pass between the two clamping blocks 8, move the first movable frame 3, make the top 11 withstand the end of the test shaft 9 away from the end of the second movable frame 4, and paste the pressure sensor on the test shaft 9 surface.

[0053] Step 2, preload the loading piston 5 to make it move downward, and remove the preload after the clamp block 8 can stably clamp the test shaft 9 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com