A meat chopping device with increased working area based on elastic force

A technology of working area and function, applied in the direction of meat processing, application, meat processing equipment, etc., can solve the problems of inability to simulate manual operation, inconvenient to continue chopping meat, and inability to realize fast meat cutting, etc., to achieve expanded range, convenient operation and The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1 As shown, the present invention provides a technical solution: a meat chopping device that increases the working area based on the elastic force, including a body 1 and a chopping board 2, a working groove 3 is provided on the right side of the body 1, and the left and right sides of the inner wall of the body 1 The sides are fixedly connected with a placement plate 4 located above the working tank 3, two groups of fine-tuning reciprocating meat chopping mechanisms 5 are arranged between the placement plate 4 and the inner wall of the body 1, and a reciprocating adjustment mechanism 6 is arranged at the bottom of the placement plate 4, and The reciprocating adjustment mechanism 6 is overlapped with the fine-tuning type reciprocating meat chopping mechanism 5 .

[0039] The left side of the chopping board 2 is fixedly connected with the body 1, and the left side of the chopping board 2 top is fixedly connected with an arc-shaped block 9. By setting the a...

Embodiment 2

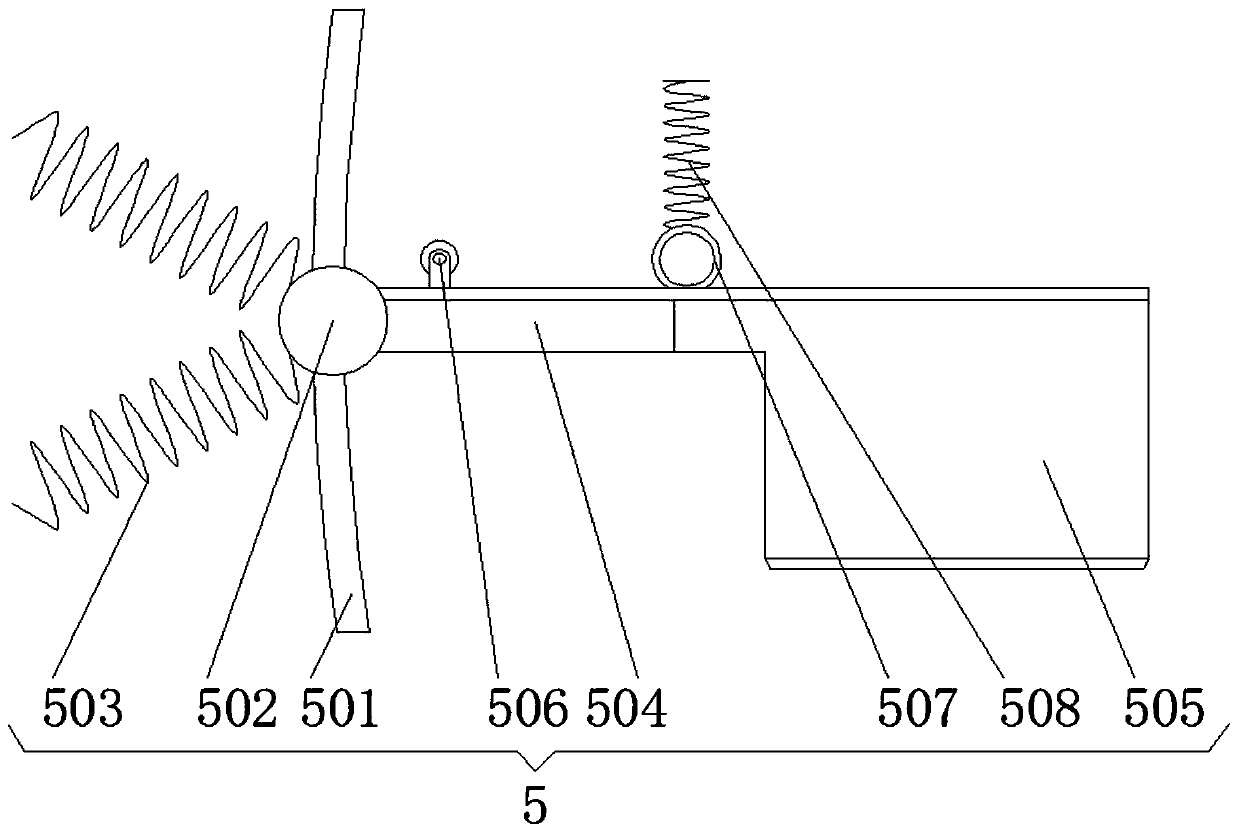

[0041] Such as Figure 1-2 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the fine-tuning reciprocating meat chopping mechanism 5 includes an arc-shaped plate 501 fixedly connected between the placement plate 4 and the inner wall of the body 1, and the arc-shaped plate 501 The right side of the arc plate 501 is provided with a concave surface, and rubber balls 502 are movably connected to the surface of the arc plate 501, and four groups of telescopic springs 503 are fixedly connected to the left side of the rubber balls 502, and between the four groups of telescopic springs 503, rubber balls 502 are left The center of the side is set symmetrically to the center. By setting the telescopic springs 503, four sets of symmetrically arranged telescopic springs 503 can give the rubber ball 502 a cushioning effect, which will not damage the rubber ball 502 and facilitate persistent work. The rubber ball 502 The right side of the fixed pla...

Embodiment 3

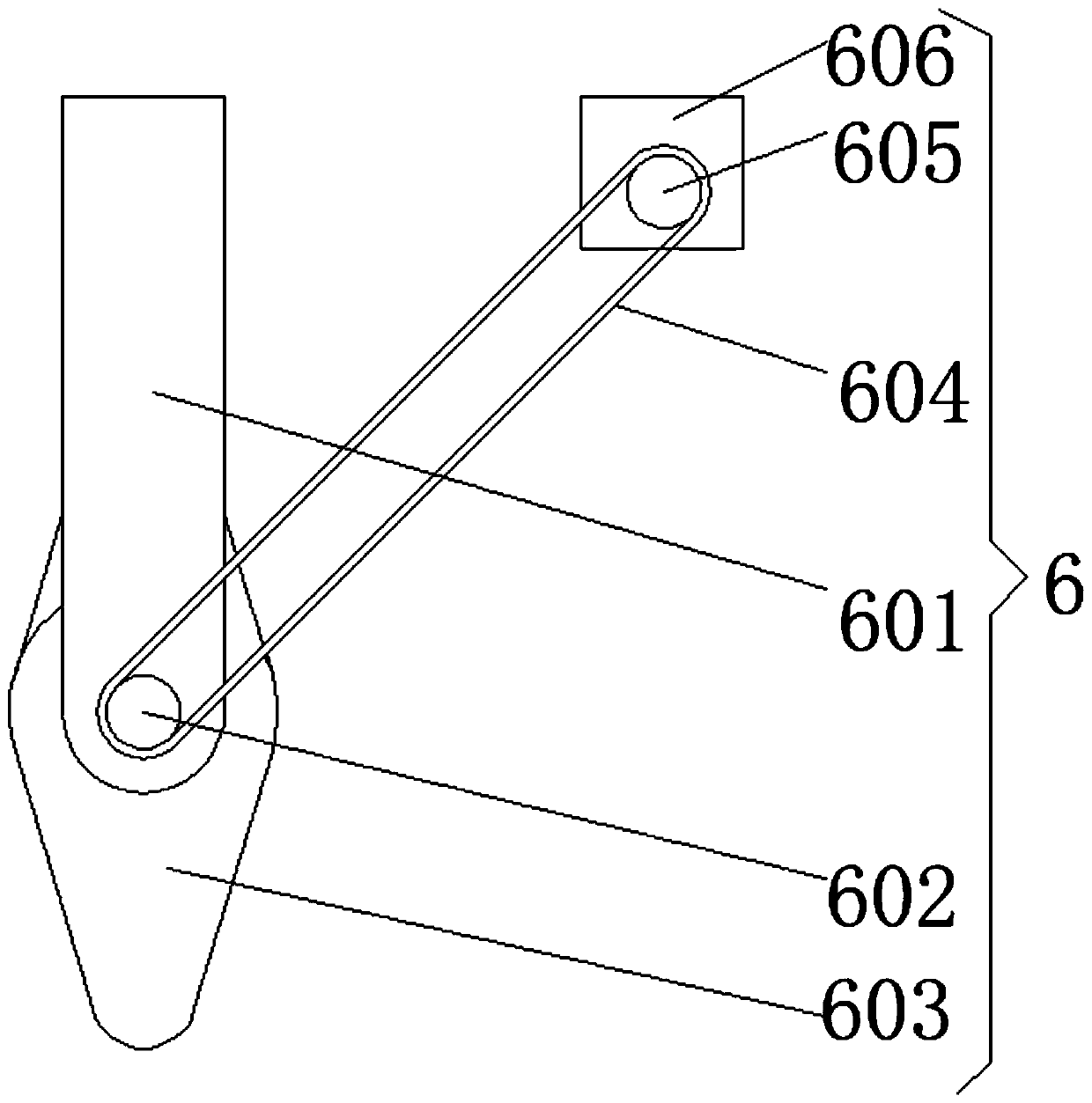

[0043] Such as Figure 1-3 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the reciprocating adjustment mechanism 6 includes a U-shaped plate 601 fixedly connected to the bottom of the placement plate 4, the concave surface of the U-shaped plate 601 is downward, And the two sides of the inner wall of U-shaped plate 601 are movably connected with rotating shaft A602, and the surface of rotating shaft A602 is fixedly connected with two eccentric wheels 603, and the direction of two eccentric wheels 603 is arranged relatively, and eccentric wheel 603 and fixed pulley 506 are flexibly connected, and the front of the rotating shaft A602 passes through the U-shaped plate 601, and the front of the rotating shaft A602 is connected to the rotating rod 605 through the transmission belt 604, and the back of the rotating rod 605 is connected to the output end of the servo motor 606 through a flat key , and the top of the servo ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap