Micro-swing type meat chopping device capable of increasing working area and simulating manual operation

A working area and swinging technology, which is applied in the direction of grain processing, etc., can solve the problems of hand soreness, inability to change the meat cutting coverage area, and reduce the efficiency of meat chopping, so as to avoid hand soreness and increase meat chopping Effect, the effect of increasing the efficiency of meat chopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

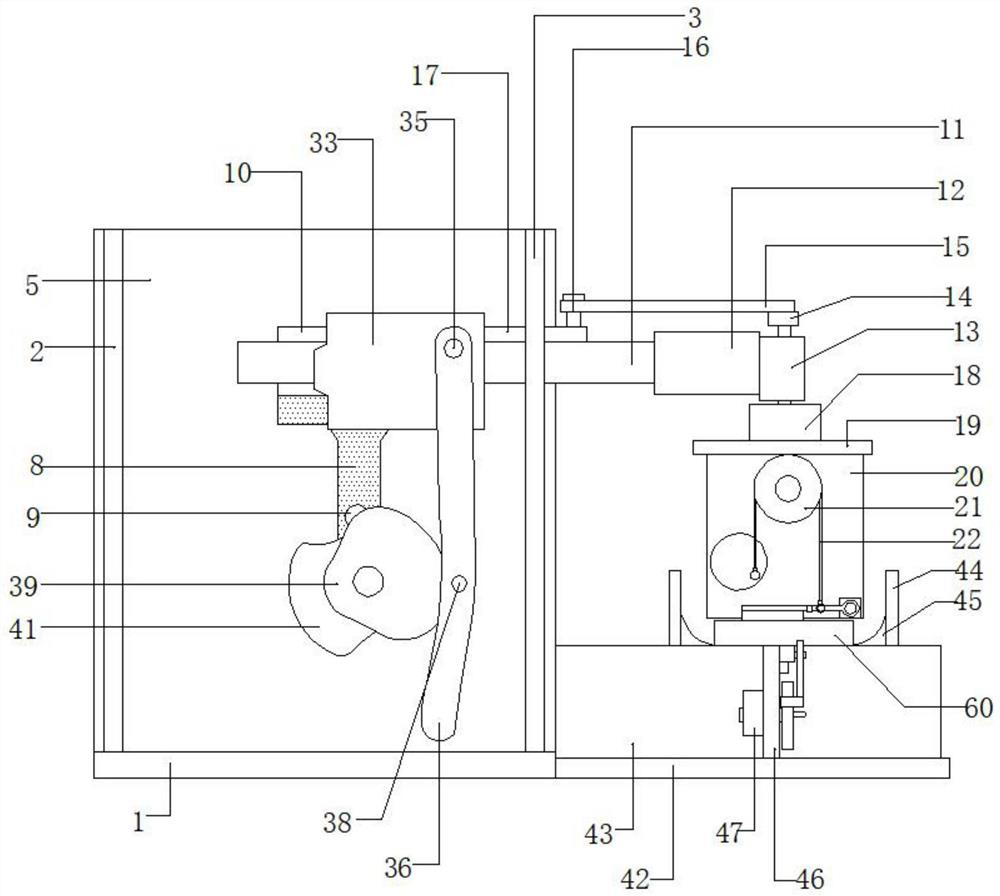

[0039] Such as figure 1 with Figure 3-5 Presented:

[0040] The present invention provides a meat apparatus having a mammatic increased working area of a simulative person to operate, and its structure includes a support bottom plate one 1, and the top side of the top portion of the support bottom plate is respectively provided with a left shaft 2 and right, respectively. The vertical panel 3 is provided with a through hole 4 at the upper center of the right vertical plate 3, and the left vertical plate 2 and one side of the right vertical plate 3 are provided with a back plate 5, the backplane 5 front A U-plate one 6 is provided at the upper center, and a longitudinal slide 7 in which a U-shaped groove having the U-plate one 6 is provided in a U-shaped tank, and the longitudinal skateboard 7 is provided. And the T type guide plate 8 is provided on one side of the U-plate one 6, and the T type guide plate 8 is provided with a limit bit rod 2 9, and the limit rod is provided on ...

Embodiment 2

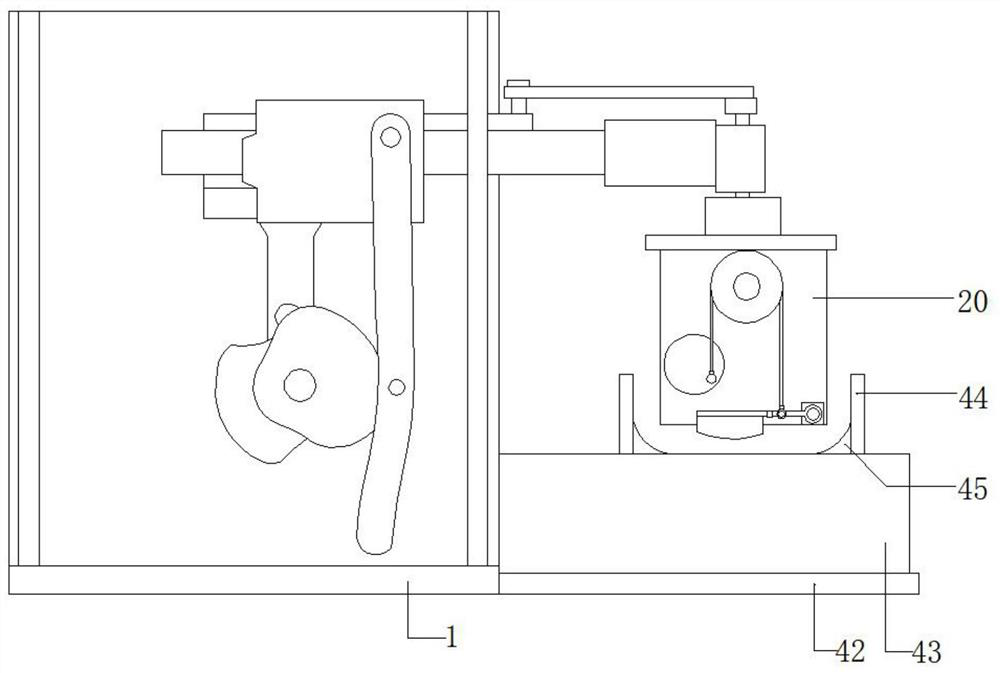

[0043] Such as figure 1 , 2 Presented:

[0044] The present invention provides a meat apparatus having a mammatic increased working area of a simulative person to operate, and its structure includes a support bottom plate one 1, and the top side of the top portion of the support bottom plate is respectively provided with a left shaft 2 and right, respectively. The vertical panel 3 is provided with a through hole 4 at the upper center of the right vertical plate 3, and the left vertical plate 2 and one side of the right vertical plate 3 are provided with a back plate 5, the backplane 5 front A U-plate one 6 is provided at the upper center, and a longitudinal slide 7 in which a U-shaped groove having the U-plate one 6 is provided in a U-shaped tank, and the longitudinal skateboard 7 is provided. And the T type guide plate 8 is provided on one side of the U-plate one 6, and the T type guide plate 8 is provided with a limit bit rod 2 9, and the limit rod is provided on one side of ...

Embodiment 3

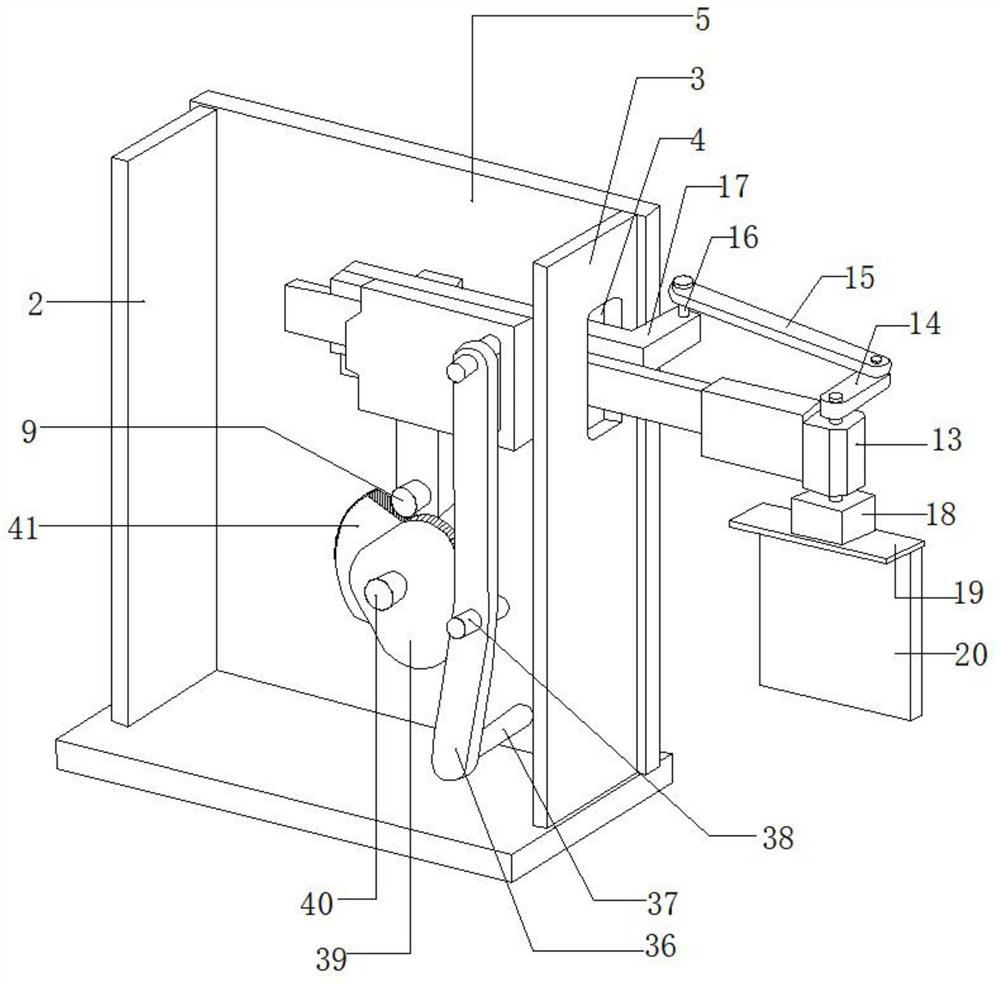

[0047] Such as figure 1 , 6 Presented:

[0048]The present invention provides a meat apparatus having a mammatic increased working area of a simulative person to operate, and its structure includes a support bottom plate one 1, and the top side of the top portion of the support bottom plate is respectively provided with a left shaft 2 and right, respectively. The vertical panel 3 is provided with a through hole 4 at the upper center of the right vertical plate 3, and the left vertical plate 2 and one side of the right vertical plate 3 are provided with a back plate 5, the backplane 5 front A U-plate one 6 is provided at the upper center, and a longitudinal slide 7 in which a U-shaped groove having the U-plate one 6 is provided in a U-shaped tank, and the longitudinal skateboard 7 is provided. And the T type guide plate 8 is provided on one side of the U-plate one 6, and the T type guide plate 8 is provided with a limit bit rod 2 9, and the limit rod is provided on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com