Bridge crack monitoring system

A crack system and bridge technology, which is applied in the directions of optical testing flaws/defects, chemical instruments and methods, cleaning methods and utensils, etc. Cracks, ease of movement, and the effect of expanding the shooting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

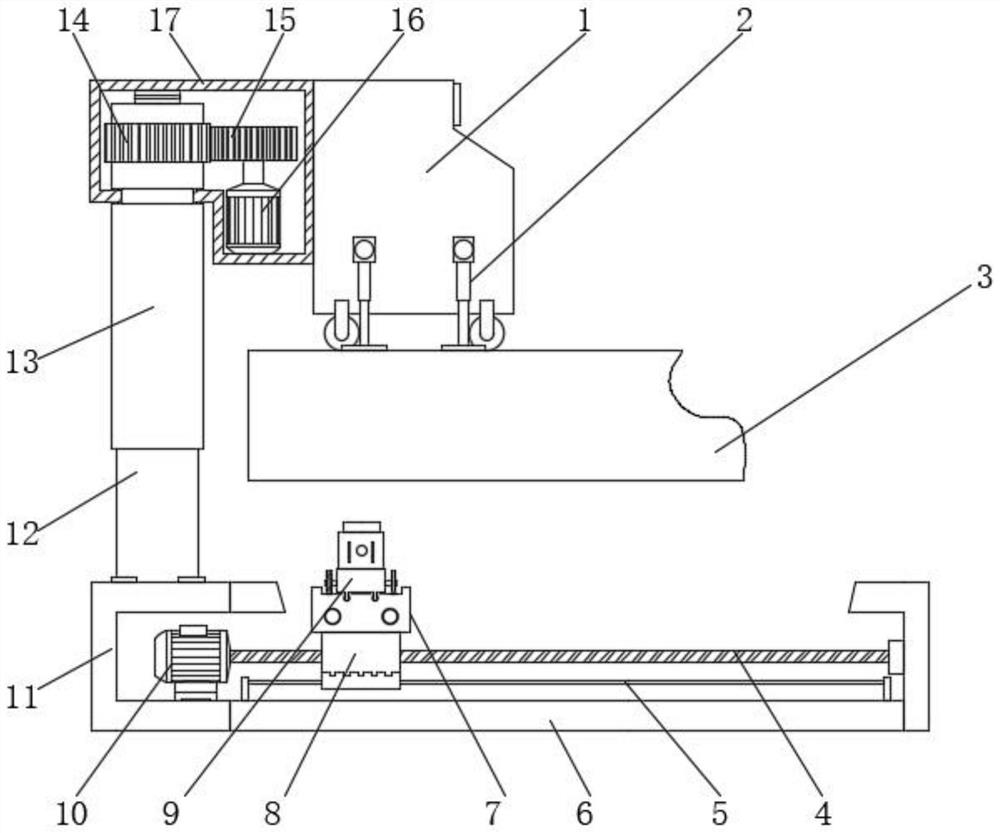

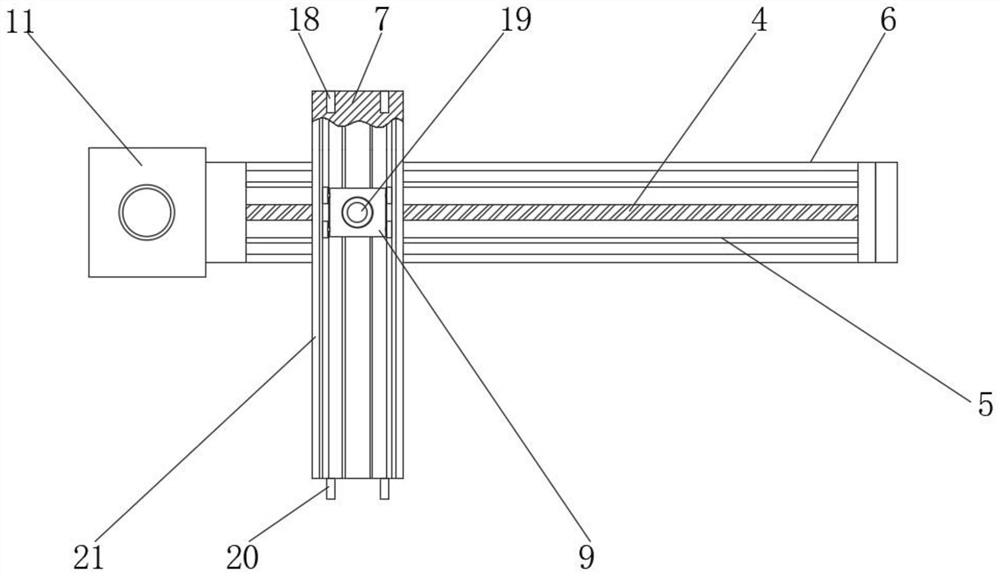

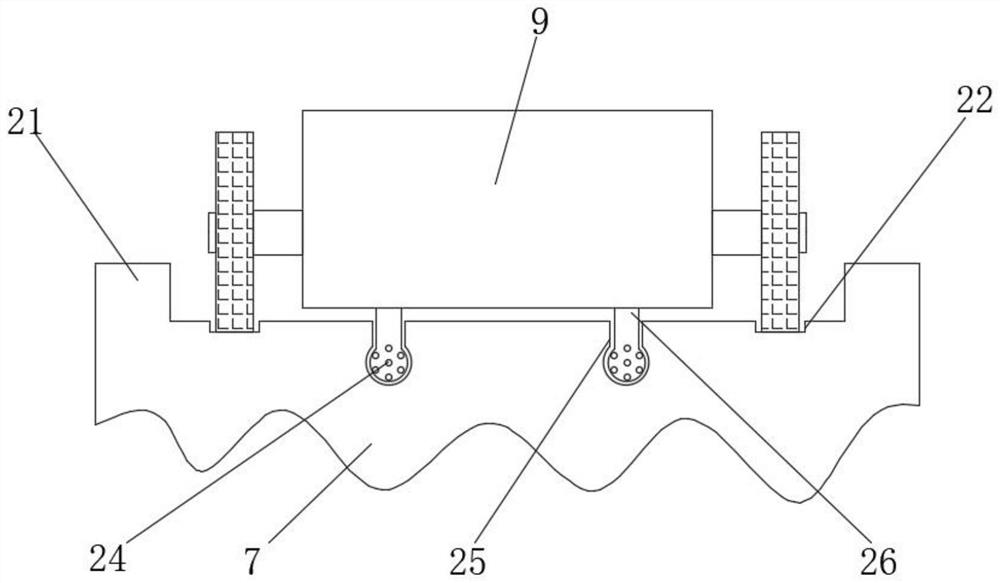

[0031] see Figure 1-6 , the present invention provides the following technical solutions: a system for monitoring bridge cracks, including a monitoring device, the monitoring device includes a monitoring platform 1, a connecting mechanism, a track mechanism, and a monitoring mechanism, the monitoring platform 1 is arranged on the top surface of the bridge deck 3, and the monitoring platform 1 A support assembly 2 for fixing is arranged on the upper surface, and an operation panel 45 is arranged on the top surface of the monitoring platform 1 .

[0032] The connection mechanism includes a protective box 17 fixed on one side of the monitoring platform 1. A vertical installation shaft is movable in the protective box 17. The bottom end of the installation shaft is fixedly connected with a hydraulic cylinder 13, and the hydraulic cylinder 13 extends out of the protective box 17. One end is connected with a push rod 12, a second motor 16 is fixedly connected in the protective box ...

Embodiment 2

[0045] see Figure 7 , the difference from Example 1 is:

[0046] Specifically, the support assembly 2 includes a plurality of mounting plates 46 fixedly connected to the outside of the monitoring platform 1, and bolts 47 are detachably installed on the mounting plates 46, wherein the monitoring platform 1 is arranged on the external vehicle through the mounting plates 46; the fixed monitoring platform After 1, move the monitoring platform 1 through the external vehicle to achieve the effect of being convenient to move and fix the monitoring device, so that the camera 19 can take pictures of the bottom of the bridge deck 3 in an all-round way.

[0047] The working principle and application process of the present invention: move the monitoring platform 1 to the working place, fix the monitoring platform 1 through the support assembly 2, open the hydraulic cylinder 13, and the hydraulic cylinder 13 drives the sliding assembly down to the bridge deck 3 through the push rod 12 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com