Distributed beam capable of independently transmitting vertical loads at multiple points and its implementation method

A technology of vertical load and beam distribution, applied in the direction of analyzing materials, using stable tension/pressure testing materials, instruments, etc., it can solve the problems of inability to load components in different positions, and the force of components does not match, so as to achieve the implementation of operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

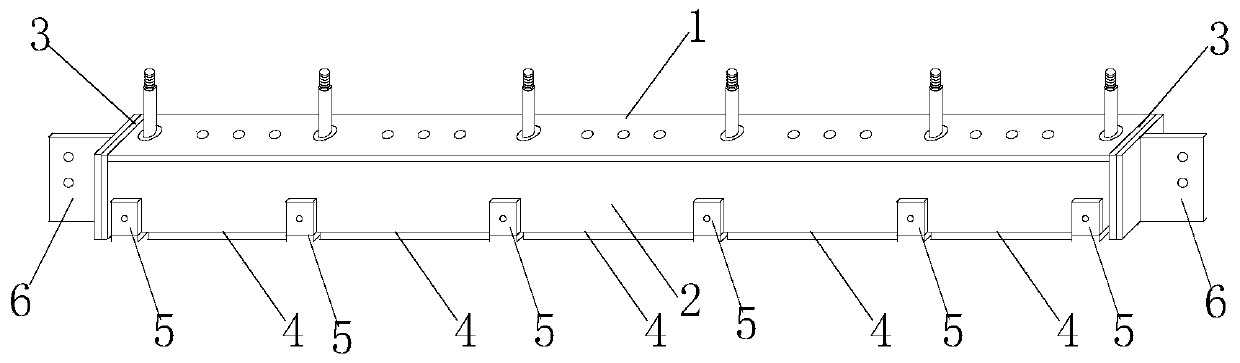

[0040] An implementation method of a distribution beam capable of independently transmitting vertical loads at multiple points and locally according to the present invention comprises the following steps:

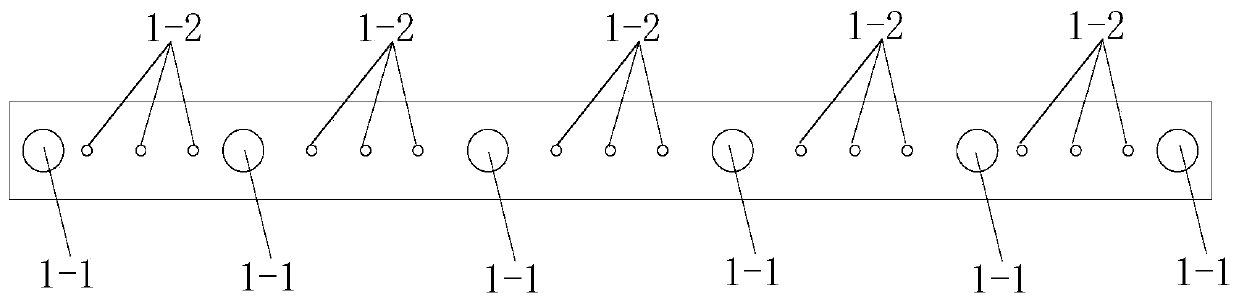

[0041] Step 1. Using steel plates as raw materials, use stamping or welding processes to mass-produce open-hole box-shaped beams, U-shaped backing plates 5-1, force transmission screws 5-2, and T-shaped pieces 6;

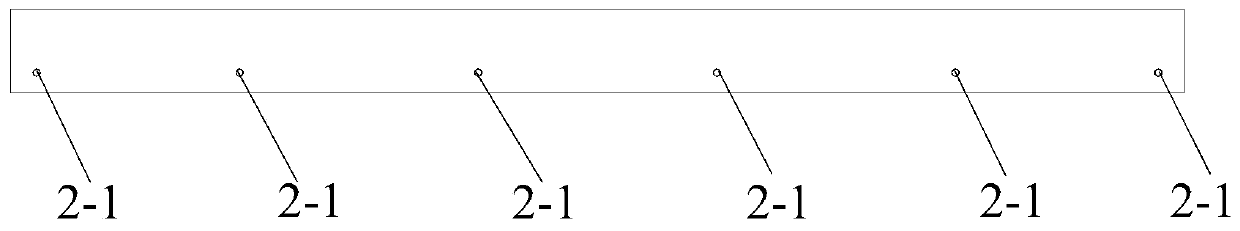

[0042] Step 2, the length of the force transmission screw 5-2 is the same as that of the bottom backing plate 5-1-1. Figure 2d The short and medium threaded end 5-2-1) is connected with the bolt holes of the bottom backing plate of the independent partial load transfer member 5, and the assembled independent partial load transfer member 5 is placed in the gap between the bottom plates 4 of the open box-shaped body beams ;

[0043] Step 3. Before the experiment starts, pass the placed independent local load transfer member 5 and the open box beam through the sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com