Three-dimensional loading large-scale three-dimensional similar simulation test load simulation method

A technology of similar simulation and load simulation, which is applied in the direction of soil material testing, material inspection products, preparation of test samples, etc., can solve problems such as small geometric ratio, stress loading process cannot maintain uniform speed, and it is difficult to achieve three-dimensional loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

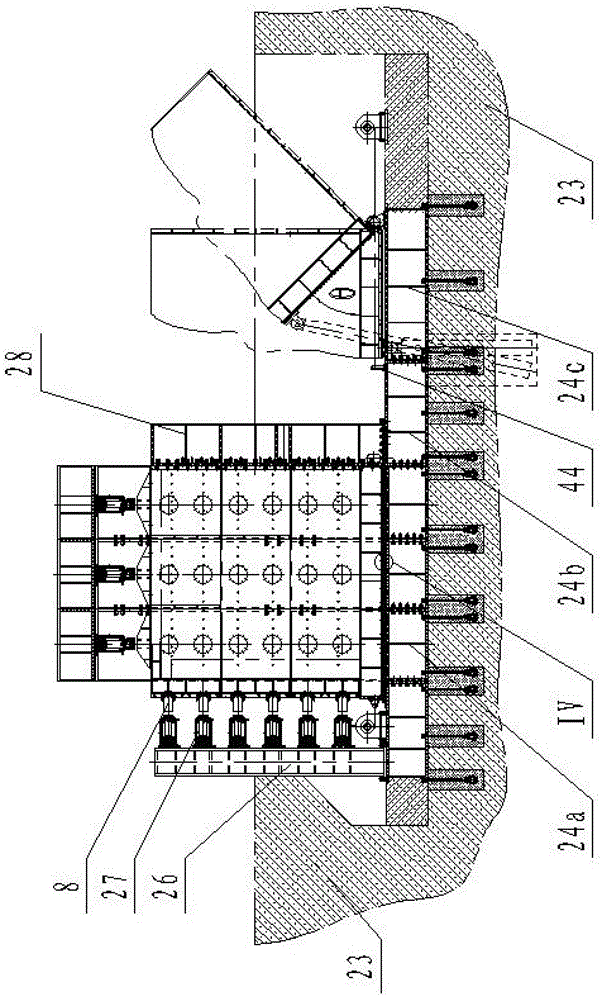

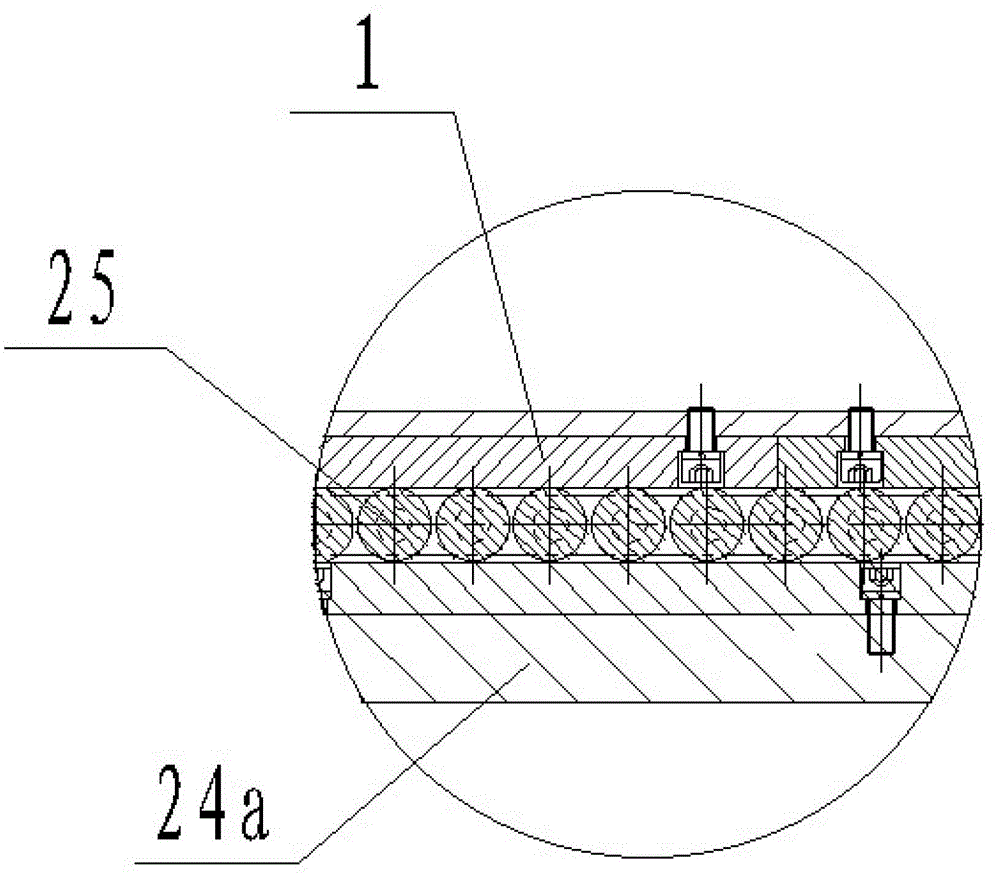

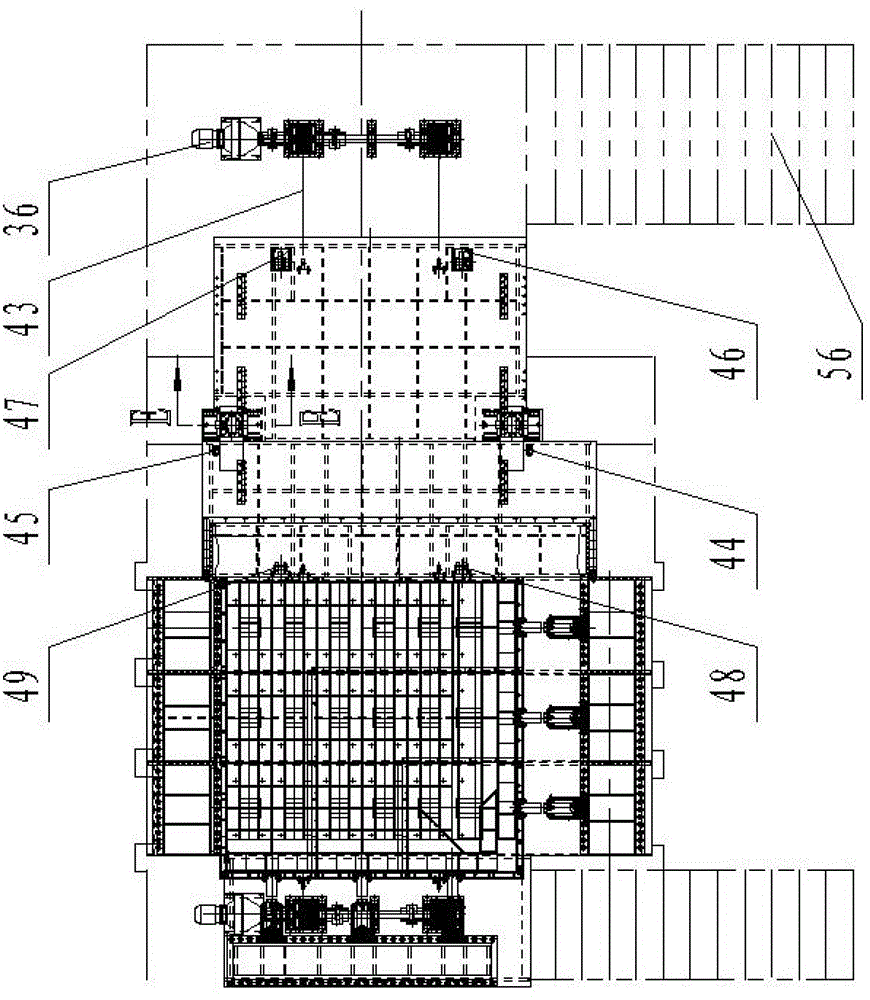

[0074] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0075] like Figure 1 to Figure 16 As shown, a three-dimensional loading large-scale three-dimensional similar simulation test system, including a test piece box and a reaction system. The test piece box includes a base 1, and the edge of the base 1 is provided with a left screw hole band 13, a right screw hole band 14, a front screw hole band 15 and a rear screw hole band 16 forming a square. The base 1 is fixedly connected with the left side plate 3 at the left screw hole band 13 by bolts, and is fixedly connected with the front side plate 5 at the front screw hole band 15 by bolts.

[0076] Between the right screw hole band 14 and the left screw hole band 13, two first middle screw hole bands 17 are arranged, and two screw hole bands respectively connected with the first middle screw hole bands are arranged between the rear screw hole band 16 and the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com