System for conveying objects from a nested stack of objects to a printer for printing

A technology of printing system and conveyor, which is applied in the field of printing on three-dimensional objects, and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] For a general understanding of embodiments of the invention, reference is made to the accompanying drawings. In the drawings, like reference numerals have been used to designate like elements throughout.

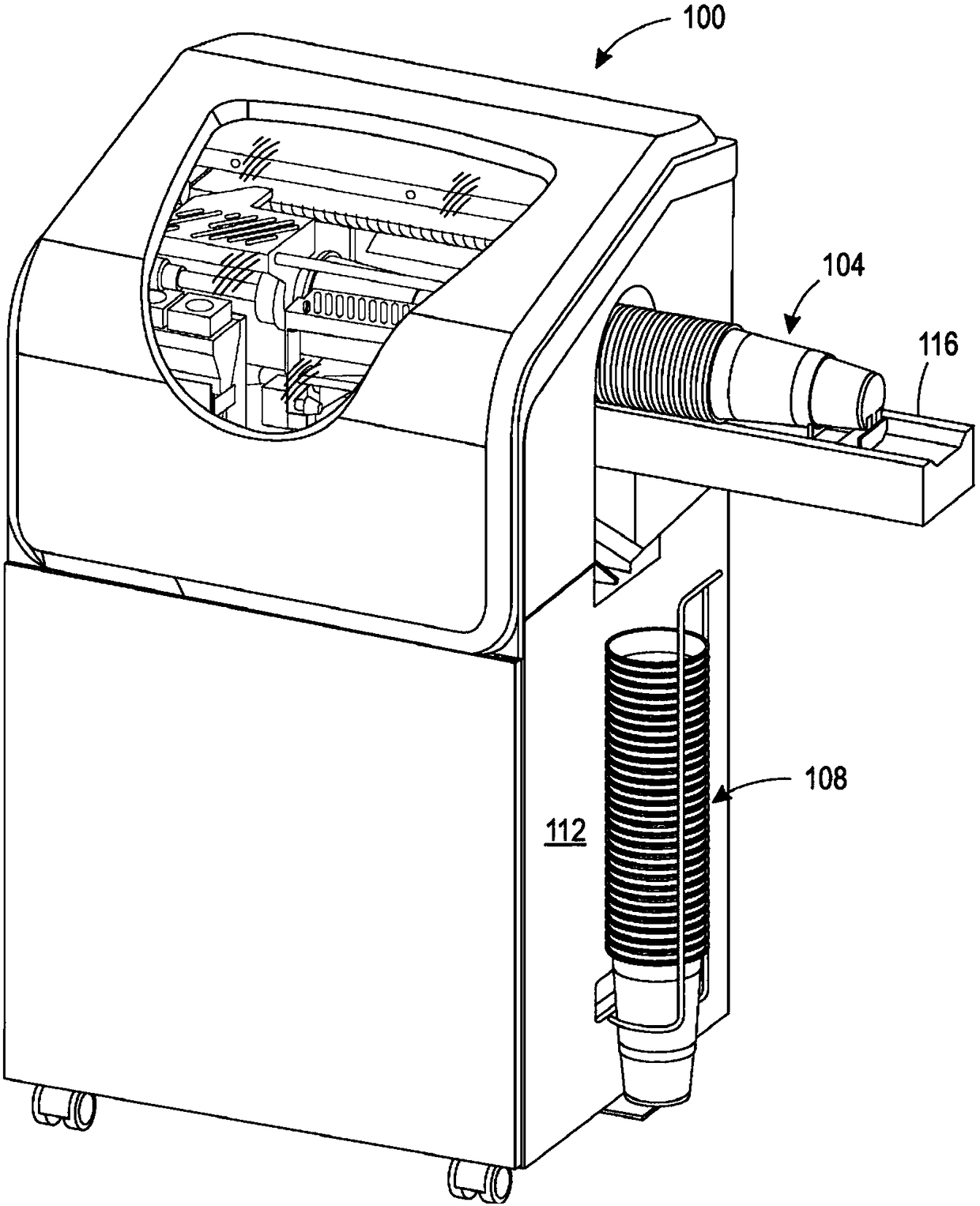

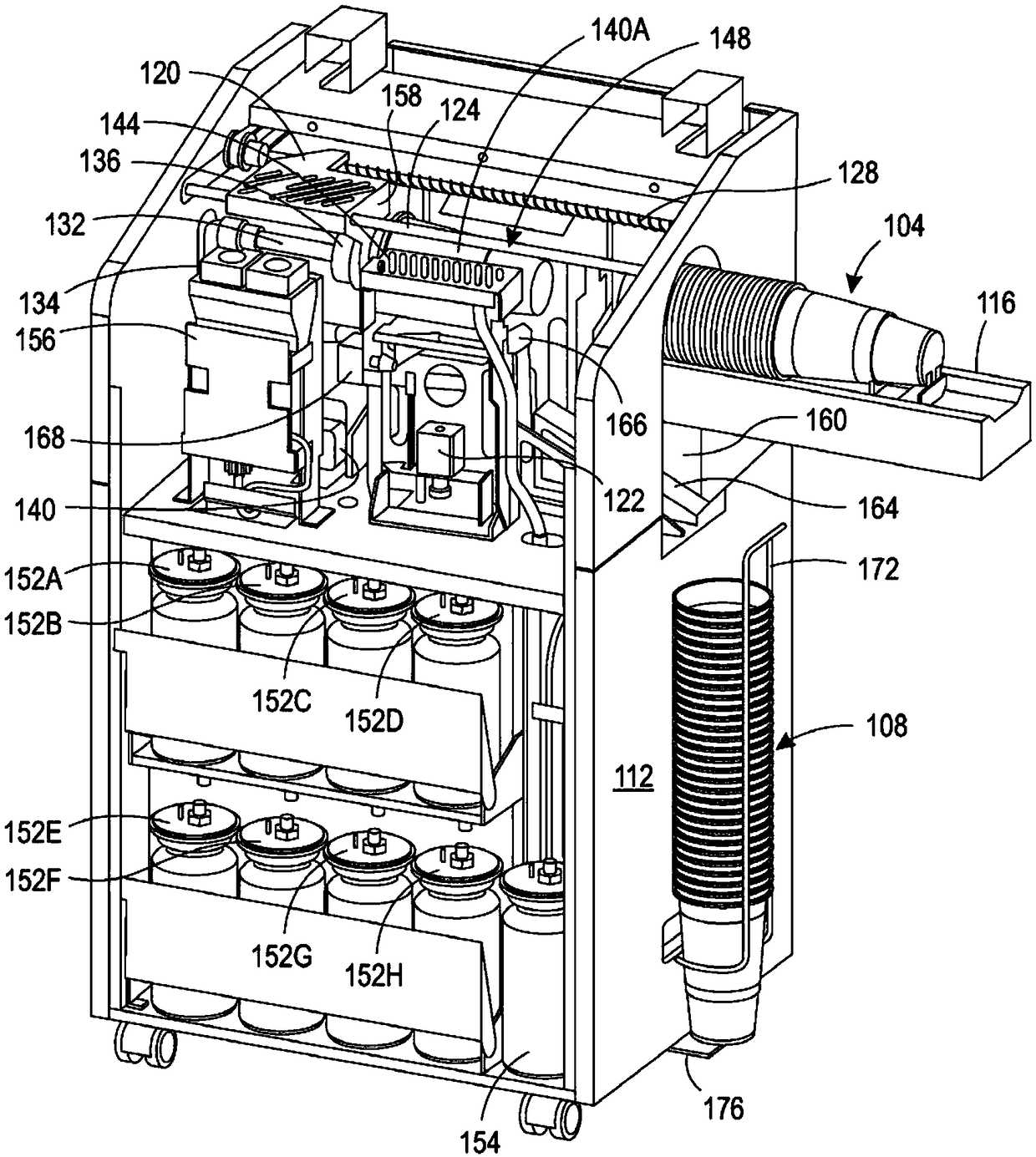

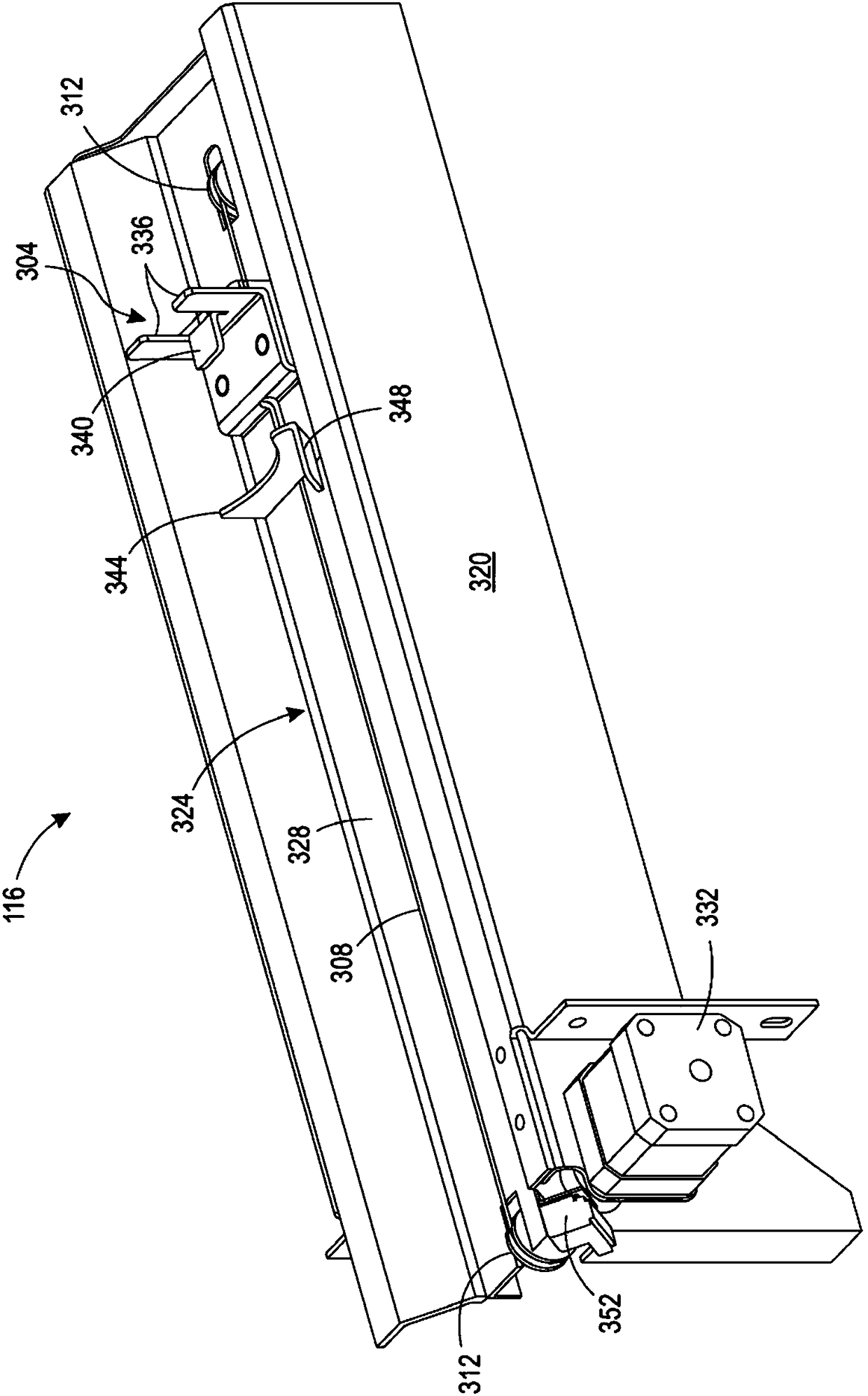

[0013] figure 1 A printing system 100 is depicted that is configured to retrieve an object from a stack 104 of nested objects, print a surface of the retrieved object, and eject the printed object into a nested stack 108 . Printing system 100 includes housing 112, such as figure 2 As shown in , the printer is positioned in the housing 112 for printing objects. As depicted in said figure, the nested stack of objects is a stack of plastic cups, but the nested stack can have any objects that can be nested together and exhibit a small hole at one end of the nested stack. Nested stack 104 is positioned within conveyor 116 for translation into enclosure 112 . Details of the conveyor structure are presented below.

[0014] exist figure 2 The internal components of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com