Engine suspension triaxial stiffness detection structure

A technology for engine mounting and detection structure, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as high price, achieve the effect of low price and avoid interference affecting performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

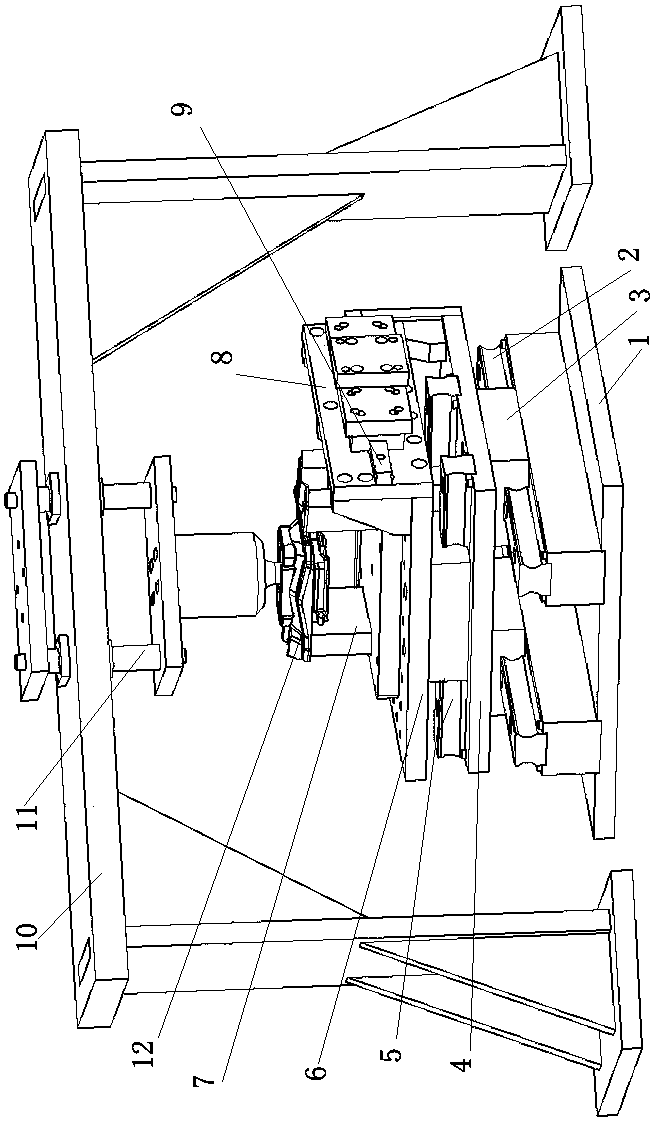

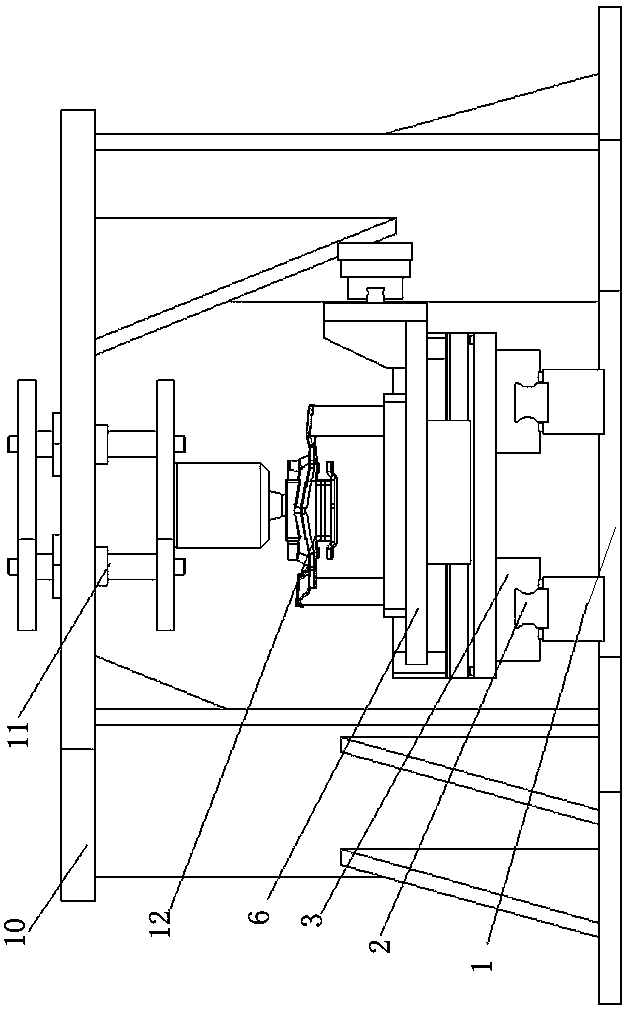

[0012] Such as figure 1 with 2 As shown, a three-axial rigidity detection structure of engine mount includes X-direction platform 1, Y-direction platform 6 and Z-direction auxiliary gantry 10, X-direction platform 1 is fixed with X-direction slide rail 2, X-direction slide rail 2 Cooperate with the X-direction slider 3, the X-direction slider 3 is fixed on the bottom of the middle platform 4, and the Y-direction slide rail 5 is fixed on the top of the middle platform 4, and the Y-direction slide rail 5 cooperates with the slider at the bottom of the Y-direction platform 6, Y The upper part of the platform 6 is provided with a sample support seat 7, the support plate 8 on the side of the Y-direction platform 6 is provided with an X-direction limiting device, and the Z-direction auxiliary gantry 10 is equipped with a vertical moving device. The vertical moving device is a linear bearing 11 assembled on the Z-direction auxiliary gantry 10 . Wherein, the X-direction limiting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com