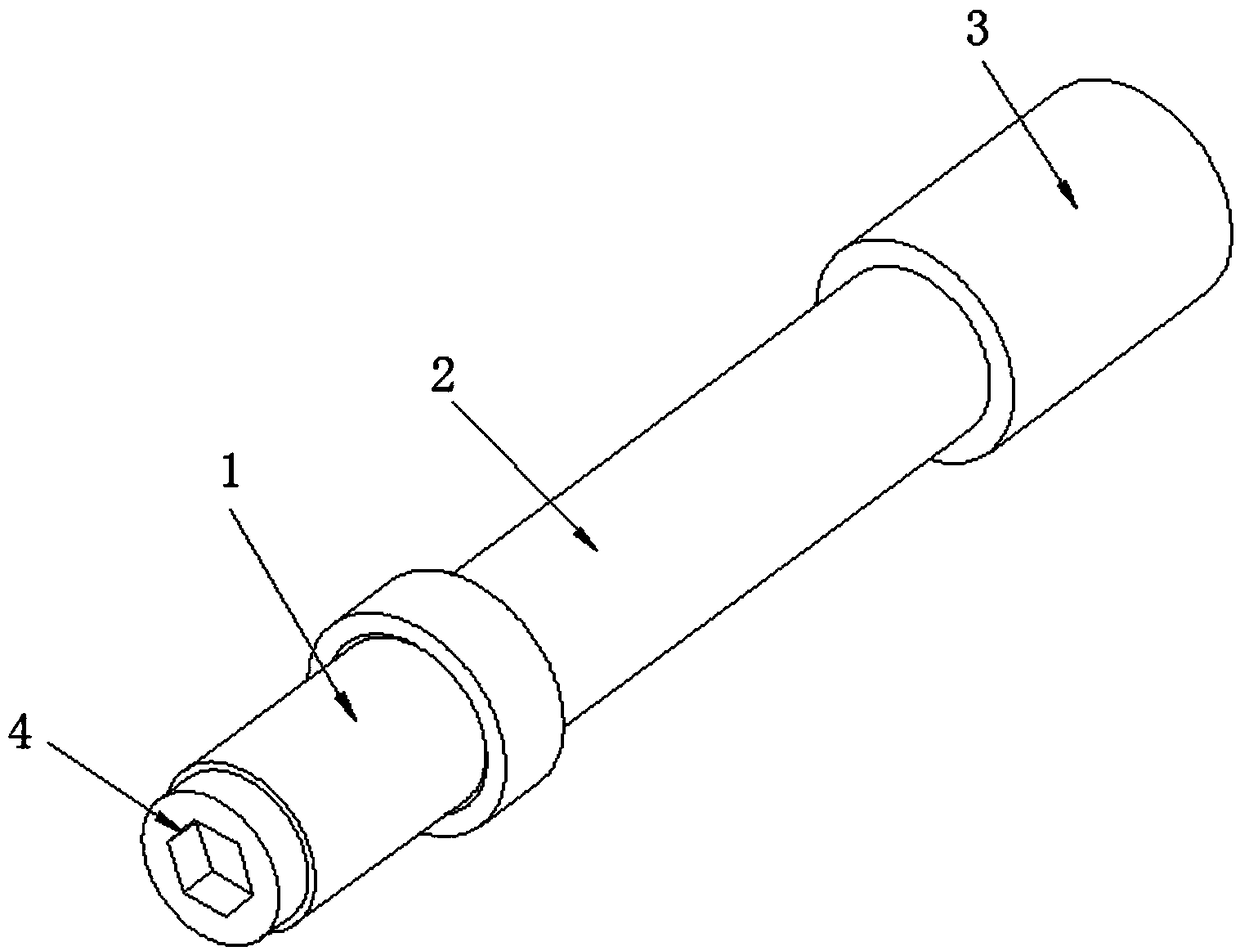

Movable shutter

A technology of shutters and resin shutters, which is applied in the field of mold accessories, and can solve problems such as slider inserts pulling products, product damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

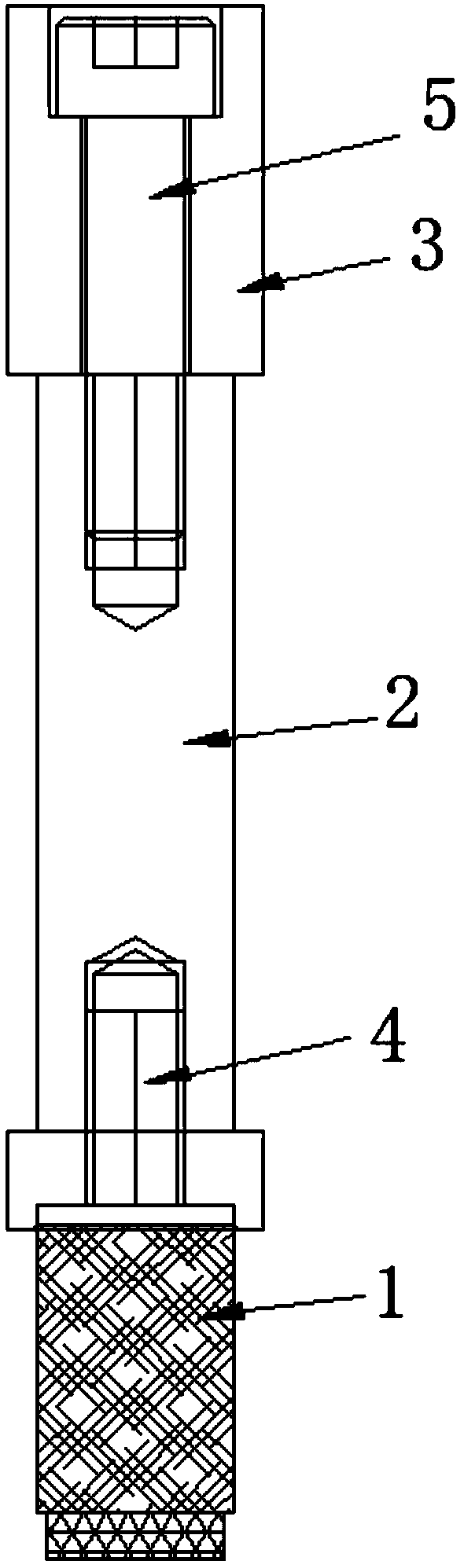

Examples

Embodiment 2

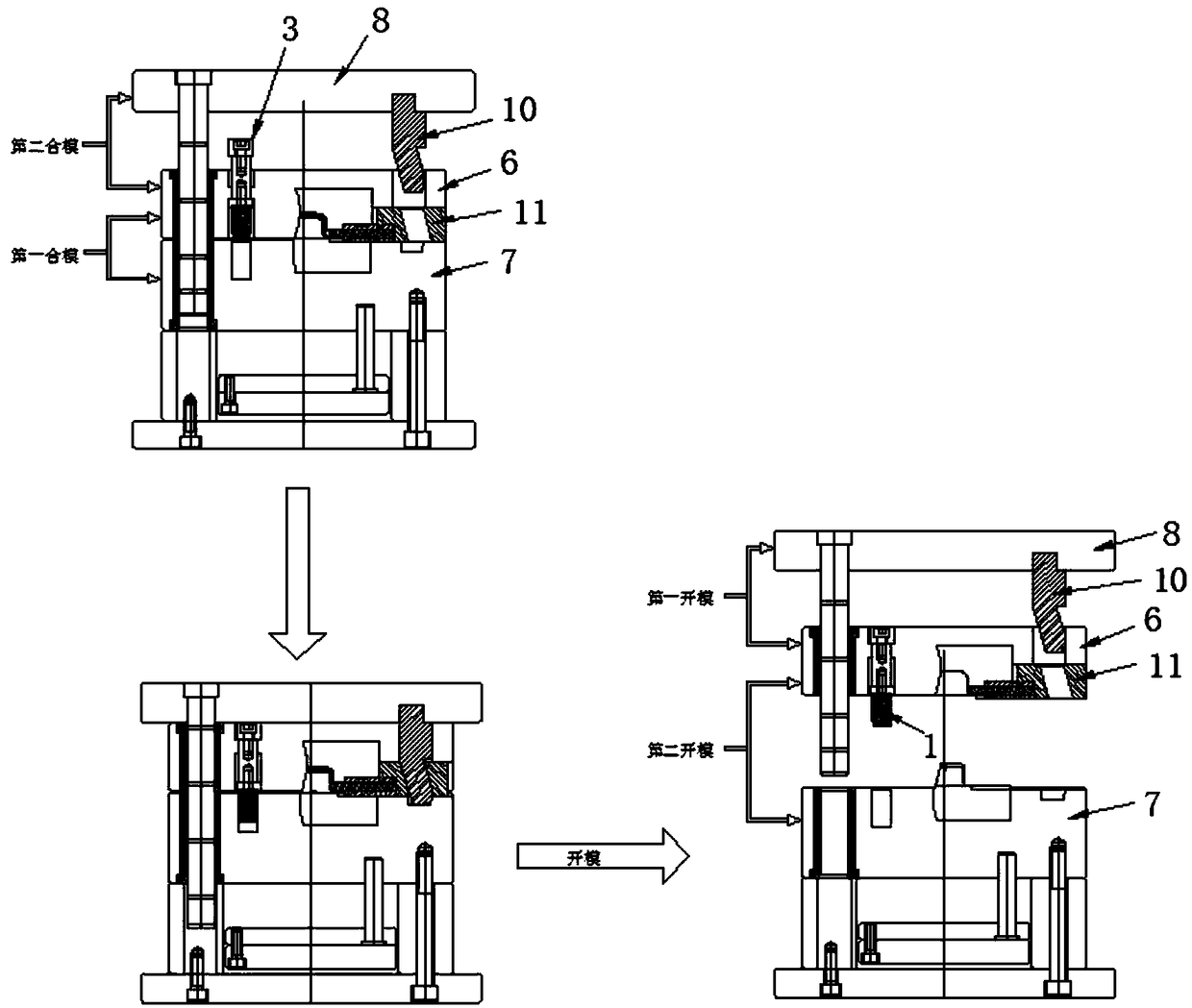

[0036] see Figure 4 , the movable shutter is applied in the mold with nozzle plate 9 in the present embodiment, and its working procedure is as follows:

[0037] 1. Mold closing:

[0038] 1.1. The first mold clamping: lower the movable template 6 and close the fixed template 7. At this time, the movable shutter that is movable in the movable template 6 is pushed up by the fixed template 7, so that the resin shutter 1 is embedded in the In the opening at the bottom of the movable template 6, and the position-limiting end at the lower end of the positioning rod 2 is in conflict with the upper wall of the opening at the bottom of the movable template 6 to realize positioning. Align the opening on the right side of the kernel to complete the first mold closing;

[0039] 1.2. The second mold closing: the panel 8 is lowered and the nozzle plate 9 is mold-closed. At this time, the lower end of the slider 10 connected to the bottom of the panel 8 is embedded in the opening in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com