Thermocouple positioning device of thermal process equipment and precision verification method thereof

A positioning device and calibration method technology, applied in the direction of electric devices, thermometers and measuring devices using electric/magnetic elements that are directly sensitive to heat, can solve the problem of wasting electric energy, poor accuracy of system test accuracy, and poor test accuracy And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

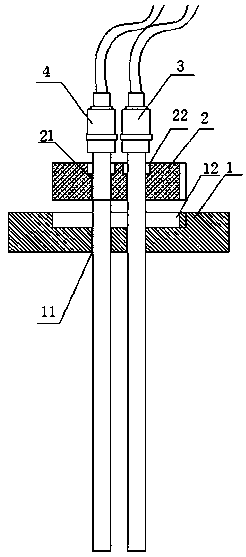

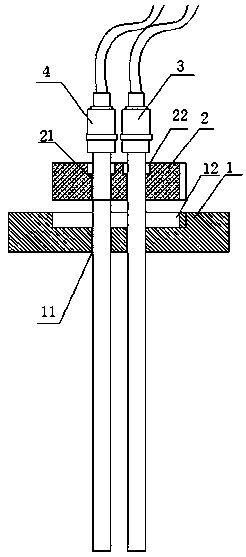

[0033] Such as figure 1 As shown, a thermocouple positioning device for thermal process equipment is used for installing thermocouples, including a chassis 1, the chassis 1 is installed on the thermal process equipment, and at least two test holes communicating with the interior of the thermal process equipment are provided on the chassis 1 11; and several positioning discs 2 with different heights, the corresponding test holes 11 on the positioning disc 2 are provided with at least two limit holes 21, the positioning disc 2 is detachably connected to the chassis 1; the thermocouple includes a test couple 3 and a calibration electrode The couple 4, the test couple 3 and the check couple 4 are inserted into the thermal process equipment through the limit hole 21 of the positioning plate 2 and the test hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com