Special-shaped part feeding and shaping mechanism

A technology of special-shaped parts and driving mechanism, which is applied in metal processing and other directions, can solve problems such as difficult clamping, prone to tilting at both ends, and incorrect posture, and achieve the effect of coordinated and unified feeding work, simple and compact structure, and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

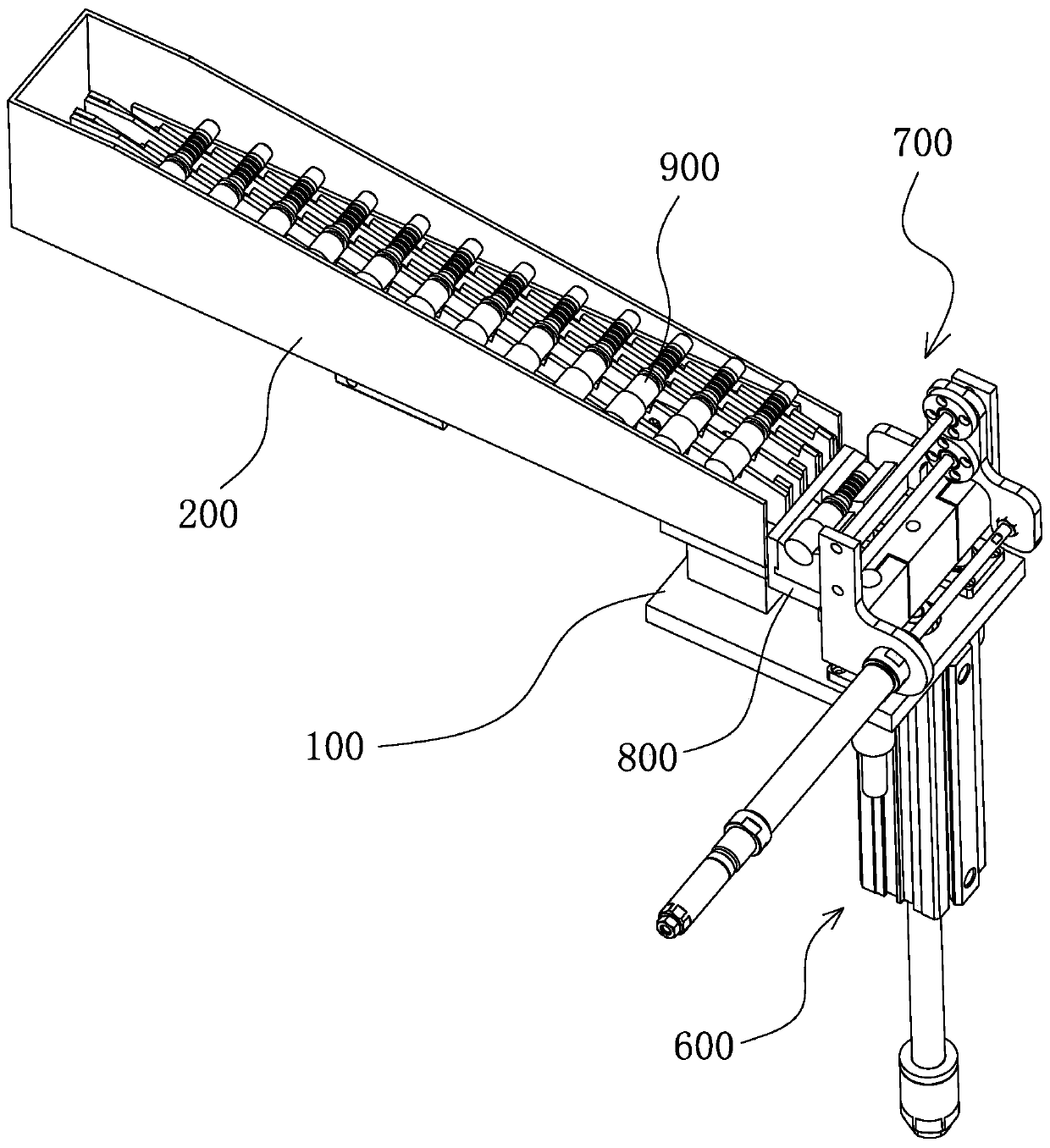

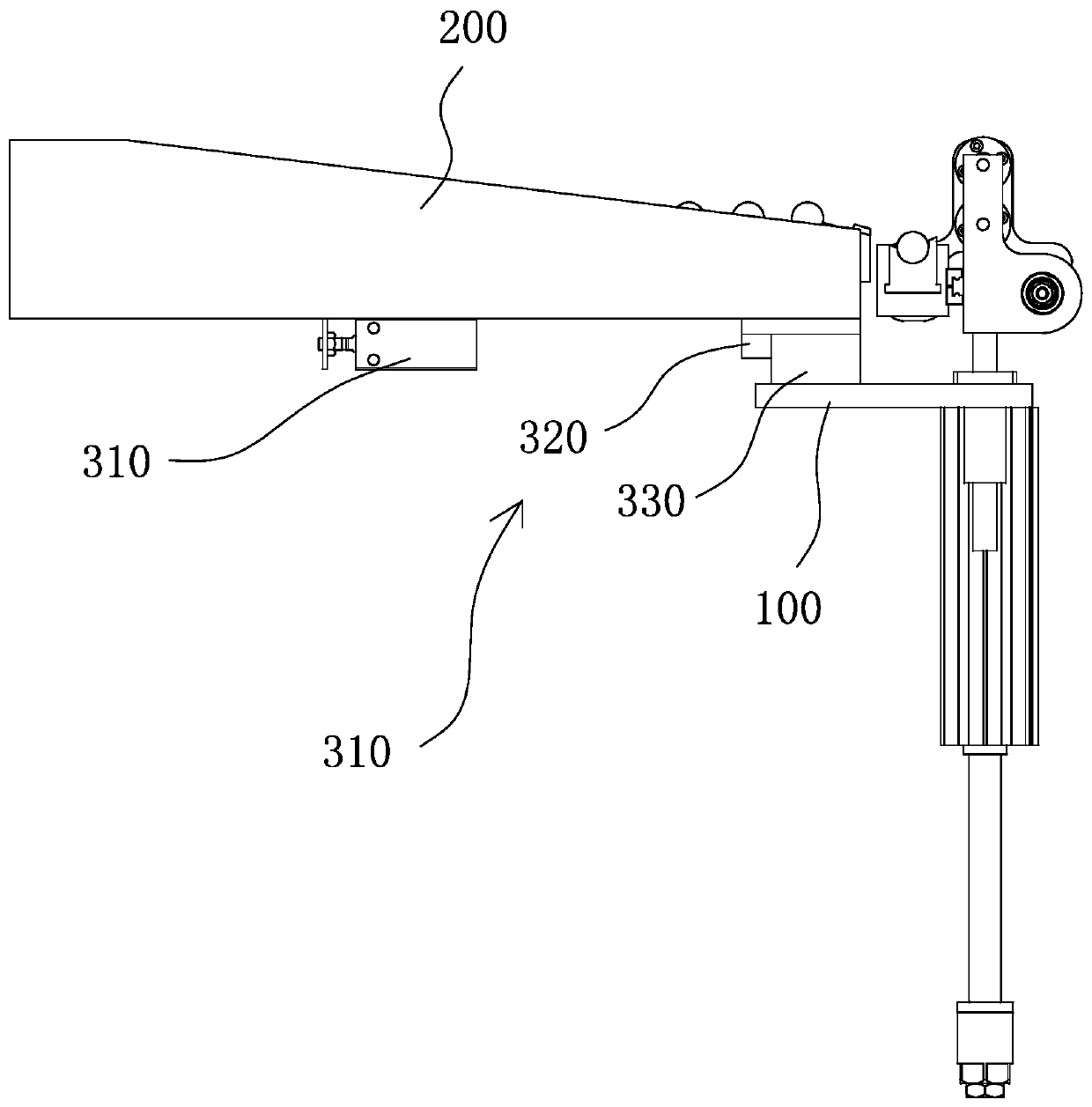

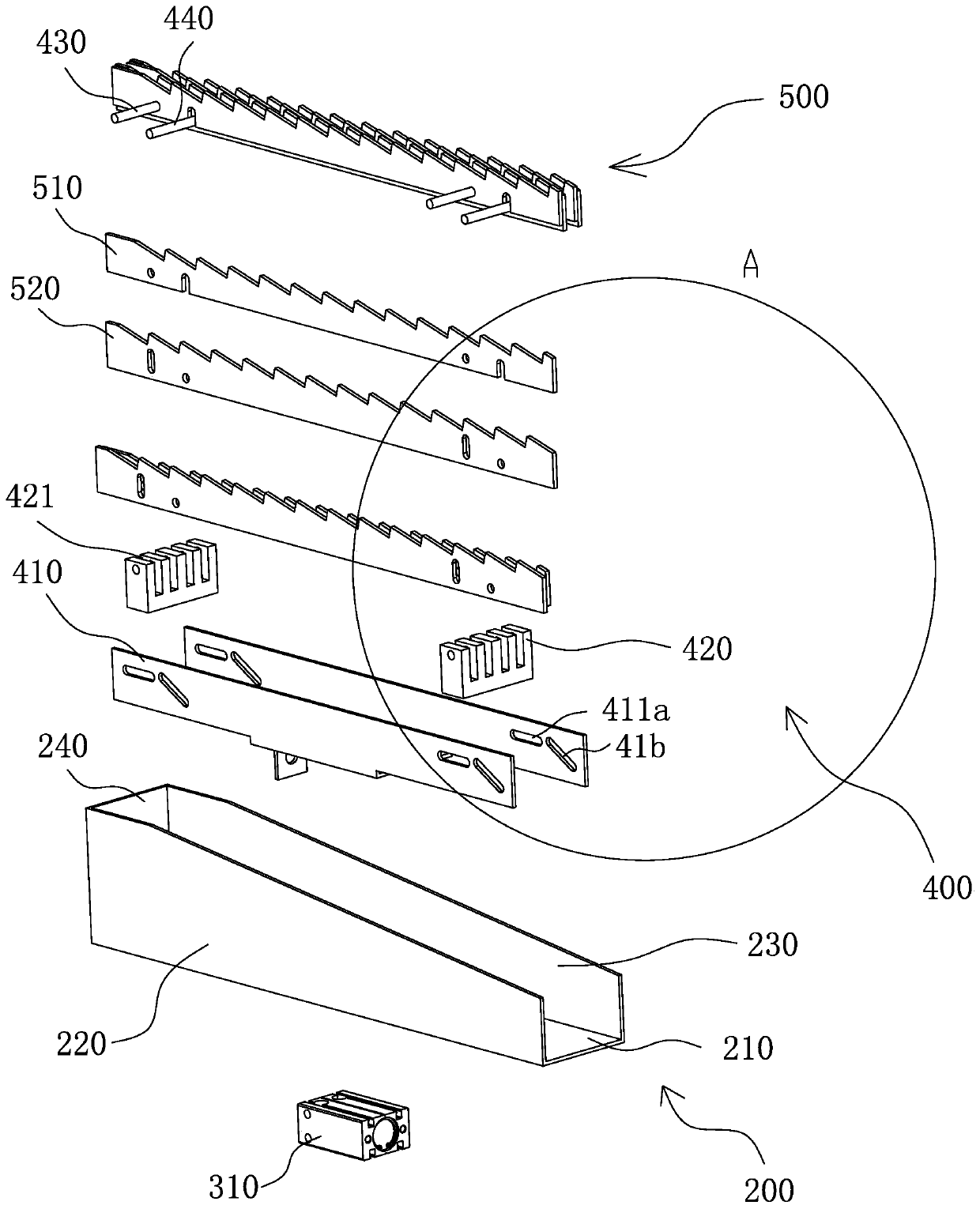

[0043] Such as Figure 1 to Figure 10 As shown, the feeding and shaping mechanism for special-shaped parts includes a support plate 100, a feeding hopper 200, a driving mechanism 300, a linkage assembly 400, several sawtooth feeding assemblies 500, a material receiving assembly 800, a lifting assembly 600, and a translation assembly 700.

[0044] The sawtooth feeding assembly 500 includes a fixed rack 510 and a movable rack 520, the upper ends of the fixed rack 510 and the movable rack 520 are respectively arranged with several first helical teeth 511, several second helical teeth 521, the first helical teeth 511 and the second helical tooth 521 have the same tooth profile and are set low at the front and high at the back. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com