Touch screen and manufacture method thereof

A production method and touch screen technology are applied in the production of touch screens and in the field of touch screens, which can solve the problems of the difference in reflectivity and affect the use experience of consumers, and achieve the effect of reducing the shadow and improving the appearance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

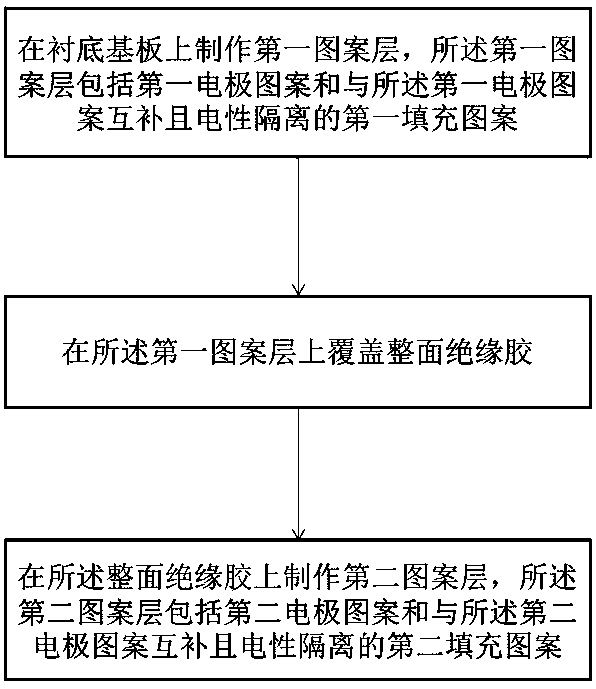

[0026] Such as figure 1 with 4 Shown, a kind of manufacturing method of touch screen comprises:

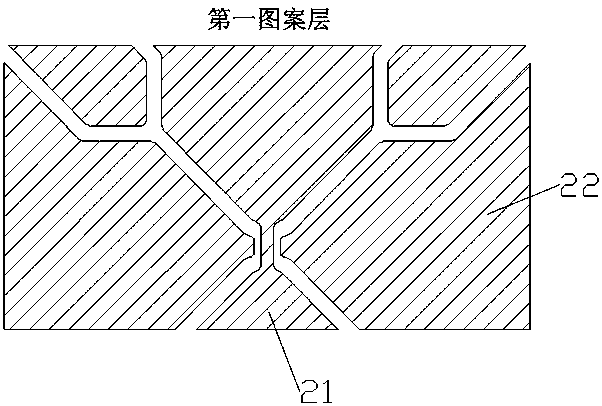

[0027] Step 1: Fabricate a first pattern layer 2 on the base substrate 1, the first pattern layer 2 includes a first electrode pattern 21 and a first filling pattern 41, the first electrode pattern 21 and the first filling pattern 41 The patterns between are complementary and electrically isolated;

[0028] In this step 1, if figure 2 As shown, the first electrode pattern 21 includes a plurality of X electrodes, and the X electrodes include a plurality of first electrode blocks distributed along the X direction, and the plurality of first electrode blocks are connected in sequence. The first electrode block can be, but not limited to, rhombus, rectangle, triangle, polygon or irregular shape.

[0029] The first filling pattern 41 includes at least one first filling block, and the first filling block may also be, but not limited to, rhombus, rectangle, triangle, polygon or irre...

Embodiment 2

[0043] A touch screen is obtained by the above-mentioned manufacturing method of the touch screen.

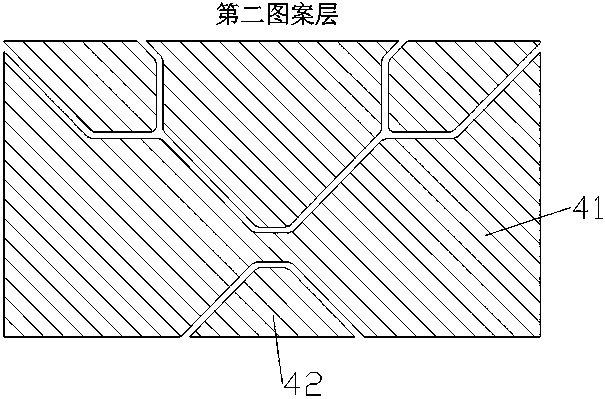

[0044] Such as Figure 4 As shown, the touch screen includes a first pattern layer 2, an entire surface insulating glue 3 and a second pattern layer 4 sequentially stacked on the base substrate 1, and the first pattern layer 2 includes a first electrode pattern 21 and a second pattern layer 4. A filling pattern 41, the pattern between the first electrode pattern 21 and the first filling pattern 41 is complementary and electrically isolated; the second pattern layer 4 includes a second electrode pattern 41 and a second filling pattern 42, the The patterns between the second electrode patterns 41 and the second filling patterns 42 are complementary and electrically isolated; wherein, the first electrode patterns 21 and the second electrode patterns 41 are criss-crossed in space.

[0045] Such as figure 2 As shown, the first electrode pattern 21 includes a plurality of X electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com