A low-level lighting fixture for a tunnel

A technology for lighting lamps and tunnels, which is applied to outdoor lighting, lighting devices, fixed lighting devices, etc., can solve the problems of unreachable reflectors, difficult maintenance and maintenance, and low lighting efficiency, so as to reduce maintenance costs and improve light energy. Utilization rate, the effect of solving the glare problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

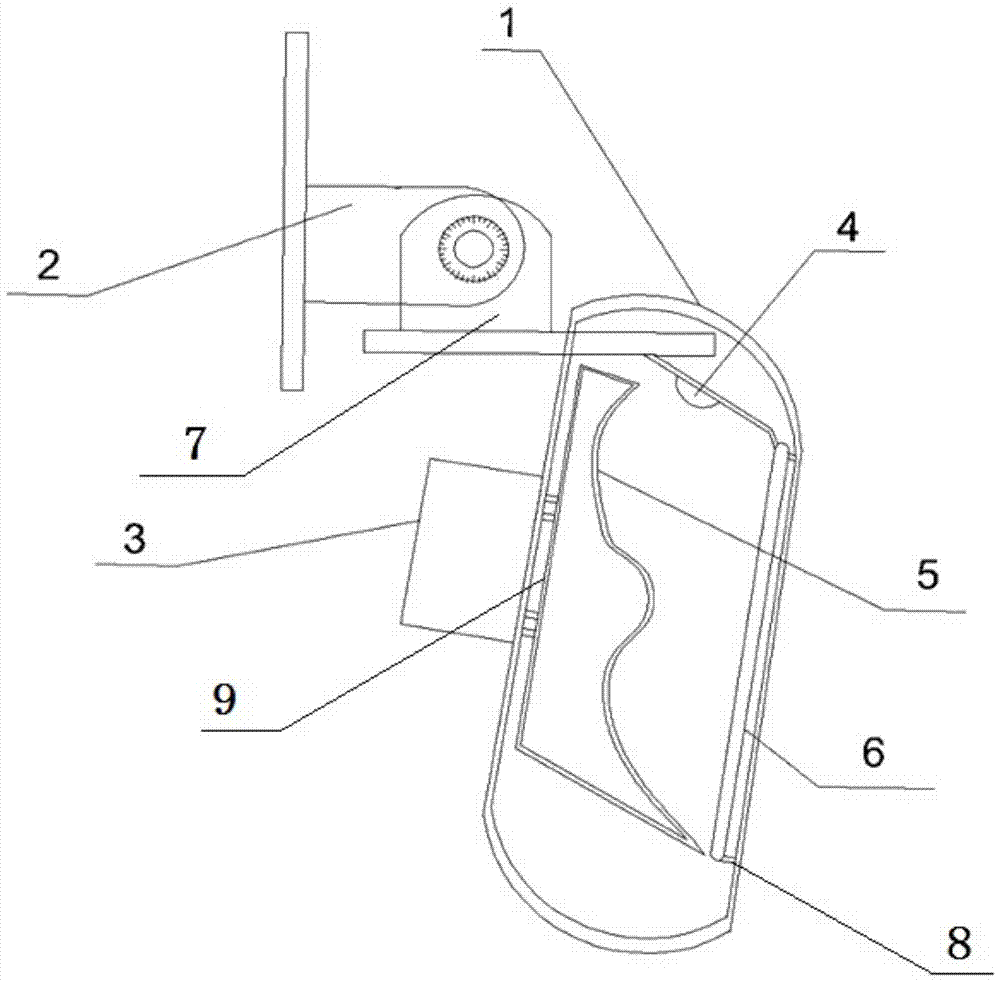

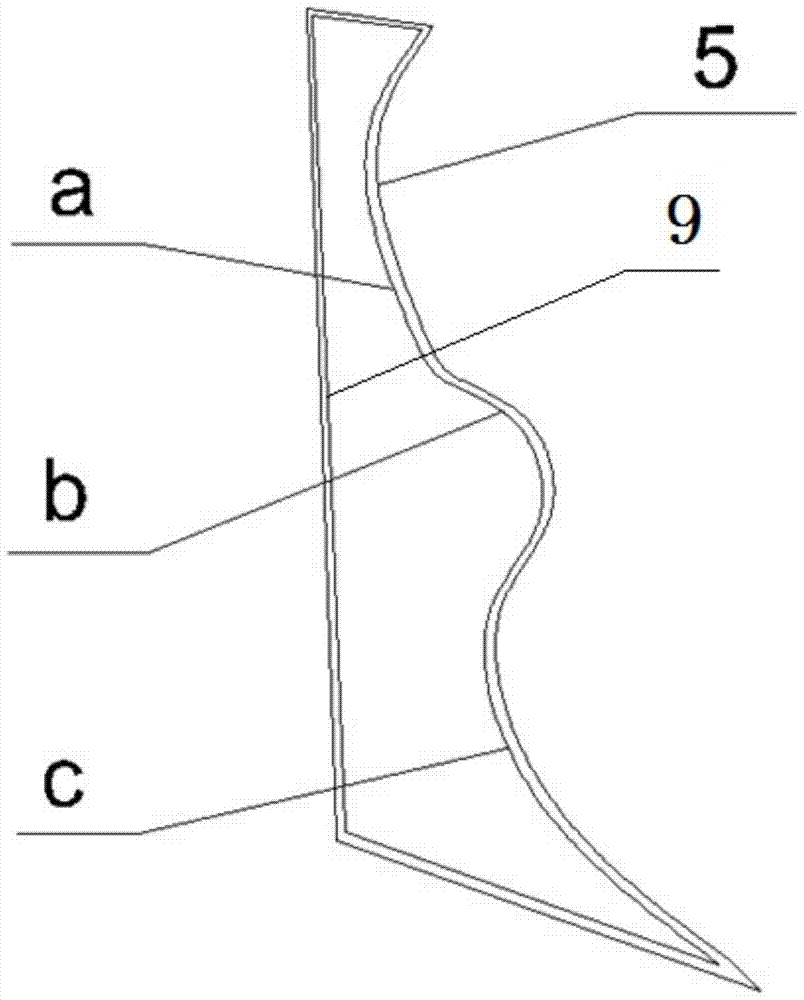

[0029] A tunnel low-level lighting fixture, which is installed on the tunnel wall at a distance of (1.0-1.5) m from the ground, including a lamp body 1, an angle-adjustable fixing bracket, a power supply box 3, a light source 4, a reflector cup 5, Glass panel 6, the lamp body 1 is arranged on the tunnel wall through the adjustable angle fixing bracket, the power supply box 3 is arranged at the rear of the lamp body 1, and the reflector 5 is arranged on the lamp body 1, the light source 4 is arranged on the upper part of the lamp body 1, the glass panel 6 is arranged on the front part of the lamp body 1, the light generated by the light source 4 is directed to the reflector cup 5, And reflected on the glass panel 6 through the reflective cup 5, the reflective cup 4 includes 2 parabolic arc surfaces and 1 free arc surface b, the free arc surface b is connected between the 2 parabolic arc surfaces, The shapes of the two parabolic arc surfaces are different, and the lengths of the...

Embodiment 2

[0033] According to the tunnel low-level lighting fixture described in Embodiment 1, the difference is that the angle between the light source 4 and the back plate 9 of the reflector 5 is 64°.

Embodiment 3

[0035] According to the tunnel low-level lighting fixture described in Embodiment 1, the difference is that the included angle between the light source and the back plate 9 of the reflector 5 is 66°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com