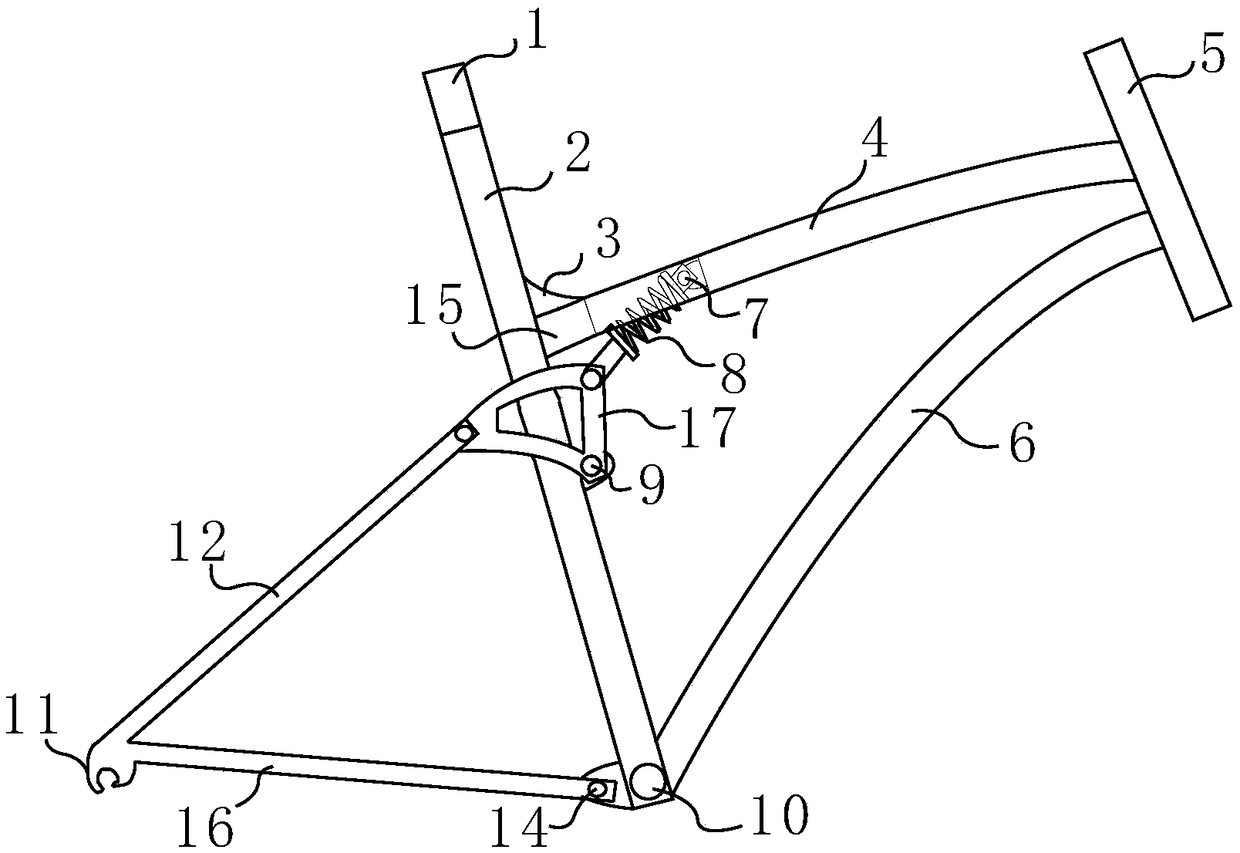

Shock-absorbing bicycle frame

A frame and vertical beam technology, which is applied in the field of shock-absorbing bicycle frames, can solve problems such as poor shock-absorbing effect, user fatigue, and affecting safe driving comfort, so as to improve safety and comfort and prevent pinching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

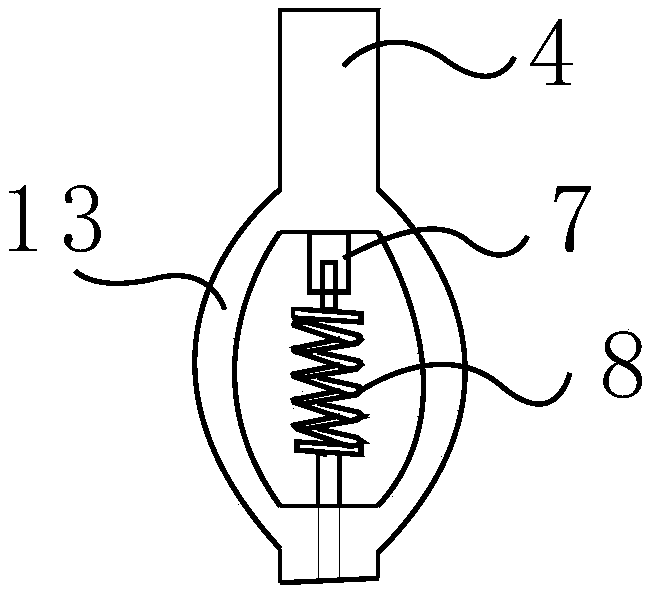

[0014] As shown in the figure, the present invention includes a front fork sleeve 5, a saddle sleeve 1, a central axis sleeve 10 and a rear axle yoke, and a vertical beam is arranged between the saddle sleeve 1 and the central axis sleeve 10 2. A slanting beam 6 is provided between the center shaft sleeve 10 and the front fork sleeve 5, and the rear axle yoke includes a rear axle upper rod 12 and a rear axle bottom rod 16, and the rear axle bottom rod 16 is rear end is fixedly connected with the rear end of the upper rod 12 of the rear axle; 2. Hinged at the connection hole 14 of the lower vertical beam, the front end of the upper rod 12 of the rear axle is hinged with a damping plate 17, and the opposite side of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com