Electrostatic dust collection board wiper

An electrostatic precipitator and board wiping technology, which is applied to the cleaning device of blackboard or slate, printing, office supplies, etc., can solve the problem of low dust collection efficiency of electrostatic precipitator board wiping, and achieve the effect of solving the low dust collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

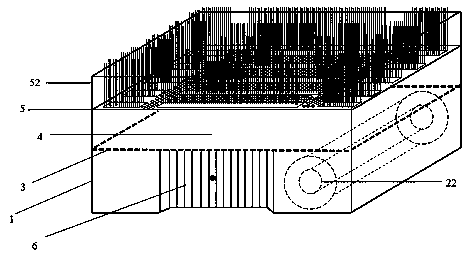

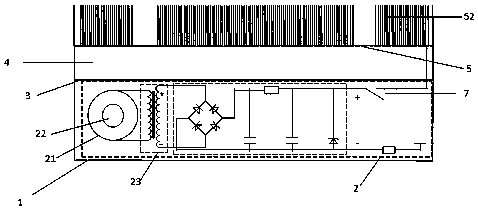

[0025] The specific embodiment of electrostatic precipitator eraser of the present invention, as Figure 1 to Figure 2 As shown, the electrostatic precipitator eraser is divided into three layers, the first layer is provided with a power generation device protection chamber 2, the second layer is a dust storage chamber 4, the third layer is a brush 52, the power generation device protection chamber 2 and the dust storage chamber 4 They are separated by an insulating partition 3, and between the dust storage chamber 4 and the brush 52 is a metal pole plate 5, which constitutes a dust-absorbing conductive part.

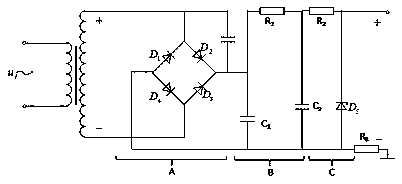

[0026] Such as figure 2 As shown, a solenoid closed circuit is provided in the protective cavity 2 of the power generating device, and the solenoid closed circuit includes a solenoid 21 and a magnetic block 22 arranged in the solenoid 21 . Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com