Control circuit and starting method for single-phase direct current brushless electric motor non-position sensor

A brushless DC motor and control circuit technology, applied in single-phase motor control, motor control, electronic commutation motor control, etc., can solve the problem of starting a one-way brushless DC motor without a position sensor, high-frequency vibration , Promote failure and other issues to achieve the effect of avoiding startup failure and improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

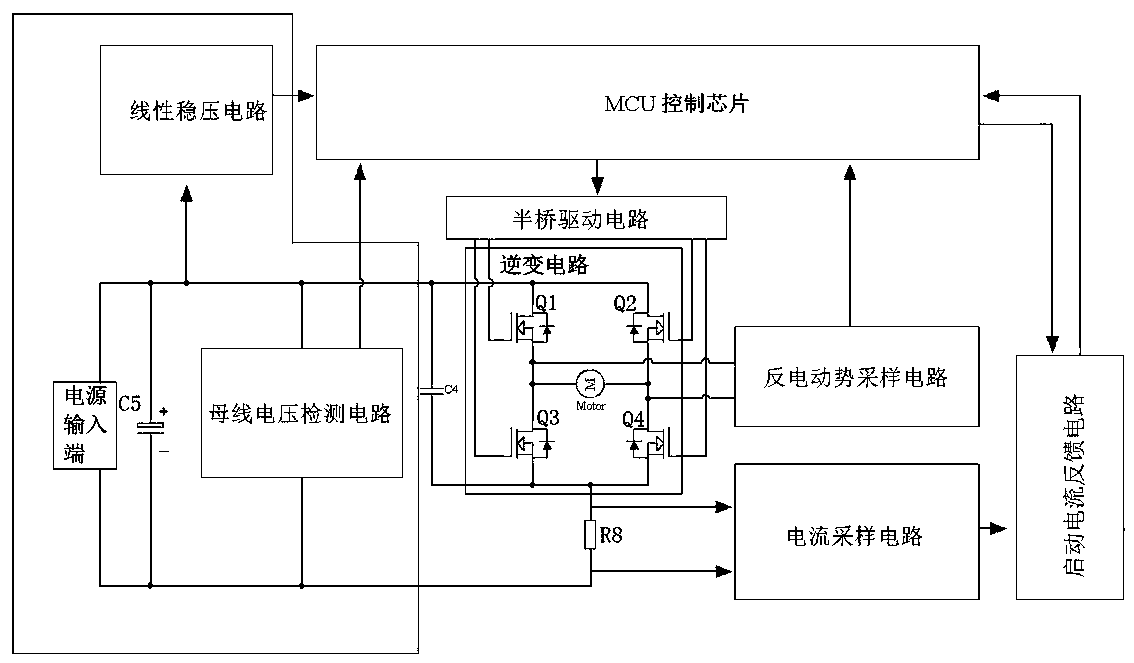

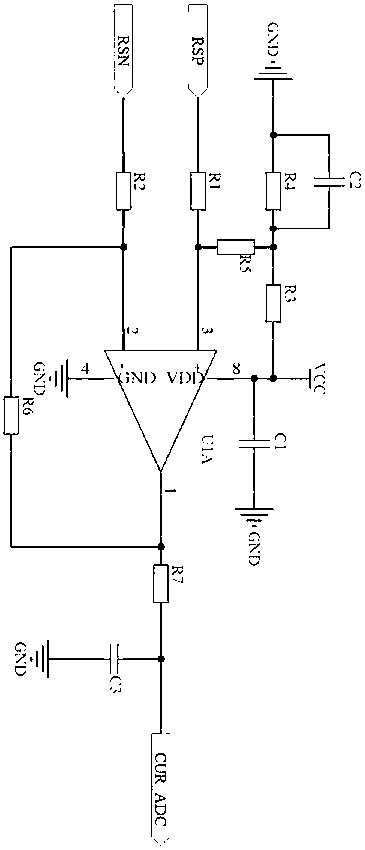

[0029] Please refer to Figure 1-3 , the present invention provides a control circuit for a single-phase brushless DC motor without a position sensor, including an MCU control chip, a power supply unit and an inverter circuit, the power supply unit is connected to an inverter circuit, and the inverter circuit is connected to a half-bridge Drive circuit, counter electromotive force sampling unit, current sampling circuit and brushless motor, the half-bridge drive circuit, counter electromotive force sampling unit and power supply unit are connected to the MCU control chip, the current sampling circuit is connected with a starting current feedback circuit, and the starting The current feedback circuit is connected to the brushless motor and the MCU control chip, and the MCU control chip is connected to the power supply unit, such as figure 1 As shown, among them, M is a brushless motor.

[0030] Specifically, the power supply unit includes a power supply input terminal, a bus v...

Embodiment 2

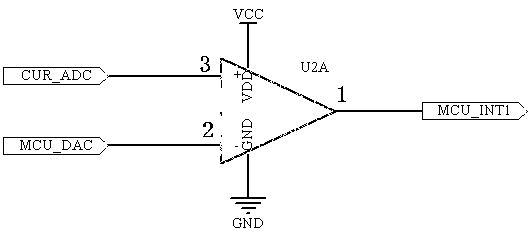

[0039] Please refer to Figure 4 and Figure 5 , the present embodiment provides a method for starting a control circuit of a single-phase brushless DC motor without a position sensor, including the following steps, S1. In the positioning stage, the rated current amplitude is set by the MCU control chip, which is different from the actual sampling current For comparison, when the actual sampling current is greater than the rated current amplitude, the excitation control is turned off, and different excitation time lengths are obtained through a single excitation of the winding coils on different phase windings, and the rotor position is determined in the static state of the rotor; S2, in In the forced push phase, set the excitation method in the same way as in the positioning phase in step S1, set the rated current amplitude and turn off the excitation time through the MCU, continuously turn on the excitation and turn off the excitation, record the duration of the turn on exci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com