Novel functionality biofertilizer

A biological and functional technology, applied in the direction of presses, manufacturing tools, stamping machines, etc., can solve the problems of bulky compaction machinery, complicated manual compaction process, and shorten the service life of compactors, so as to increase the safety of equipment use Sexuality, increase the convenience of moving and handling, and increase the effect of equipment stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

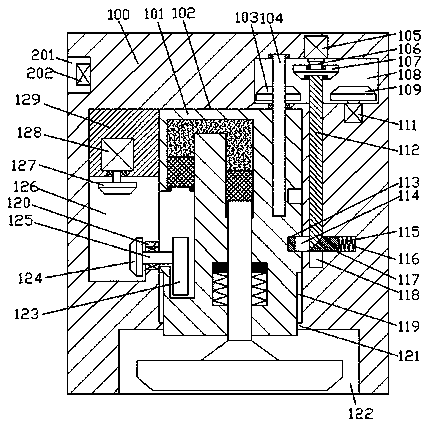

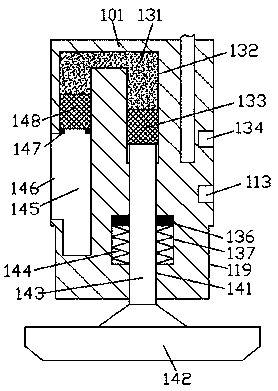

[0014] Combine below Figure 1-2 The present invention will be described in detail.

[0015] refer to Figure 1-2 , a novel functional bio-fertilizer according to an embodiment of the present invention, comprising a base 100, a cavity 122 is provided in the end surface of the bottom of the base 100, and a positioning cavity is provided in the top wall of the cavity 122 102, a position adjustment frame 101 is installed in the position adjustment chamber 102 with sliding fit, and a first sliding groove 141 is provided in the bottom end surface of the position adjustment frame 101, and a push groove 141 is installed in the first sliding connection groove 141 for sliding fit. The ejector rod 143, the ejector rod 143 extends into the cavity 122 and the bottom end is fixed with a compacting block 142, and the inner walls of the left and right sides of the first sliding groove 141 are symmetrically provided with guide grooves 137, A guide block 136 fixedly connected to the ejector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com