Caster connector with variable height

A connector and variable technology, applied in the lubrication of casters, wheels, engines, etc., can solve the problems of poor anti-vibration effect of casters and non-adjustable height of casters, and achieve good anti-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

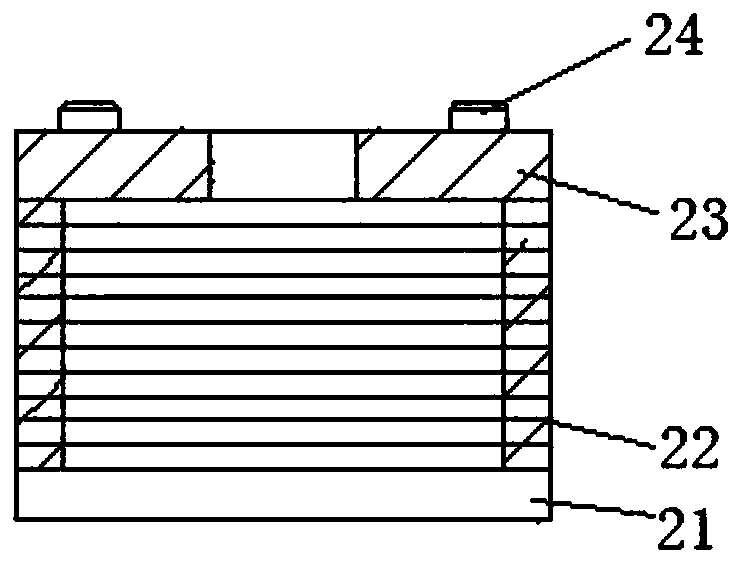

[0023] Embodiment one, see figure 1 , a height-variable caster connector, including a base plate 21, a number of height-adjusting backing plates 22 padded on the bottom plate, and a pressure plate 23 located on the uppermost backing plate. Pressing plate is connected together with base plate by the connecting screw rod 24 that passes pressing plate and height adjustment backing plate simultaneously. The connecting bolts are directly threaded on the base plate. The rubber wheels are connected to the bottom plate during use. The object supported by the casters is attached to the pressure plate.

Embodiment 2

[0024] Embodiment two, the difference with embodiment one is:

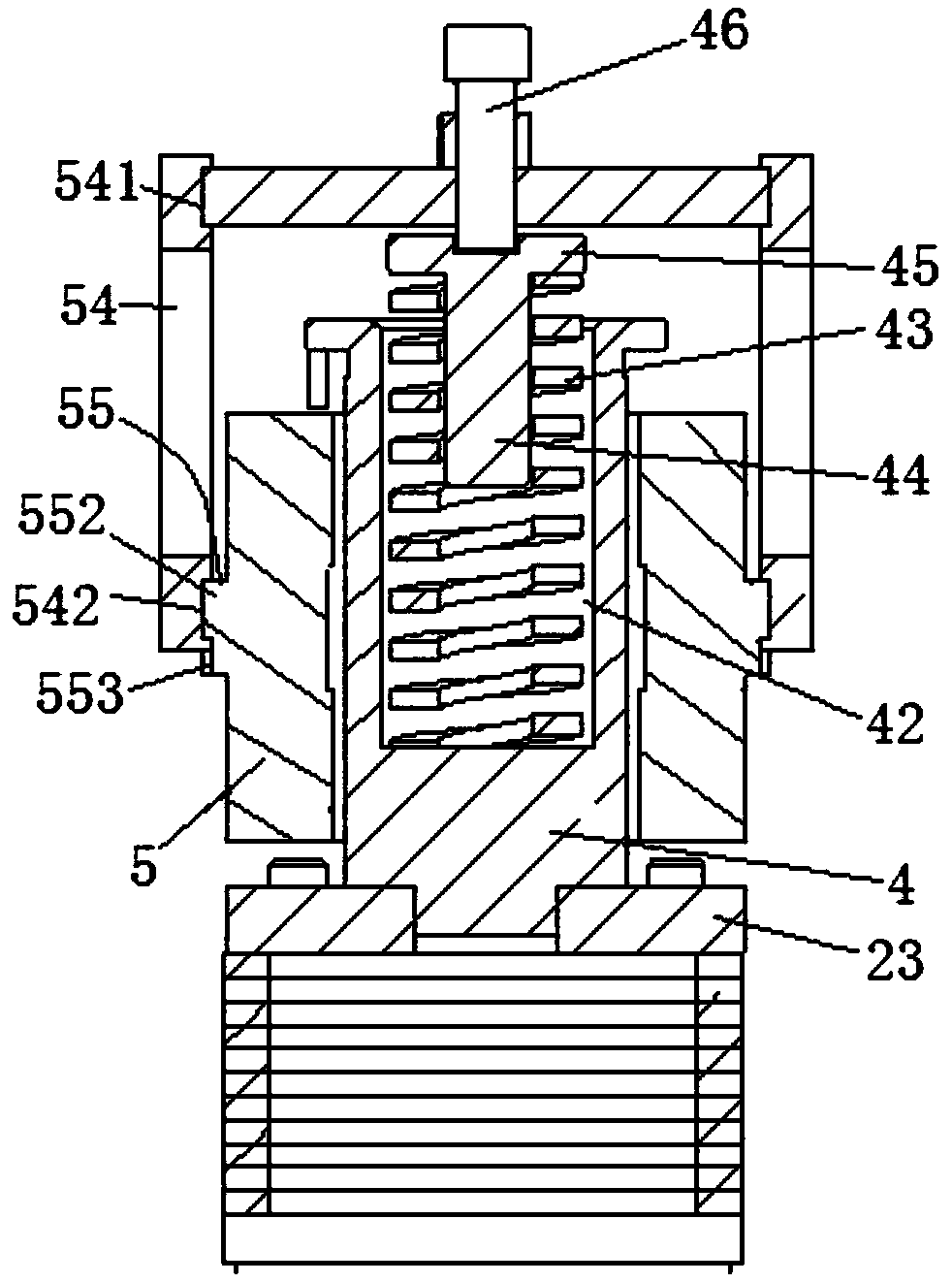

[0025] see figure 2 , the pressing plate is provided with a central column 4. A connecting sleeve 5 is sheathed on the central column. The connecting sleeve is provided with two connecting plates 54 evenly distributed along the circumference of the connecting sleeve. The connection sleeve 5 is provided with a connection protrusion ring 55 extending along the circumference of the connection sleeve. Threaded connection holes extending along the up and down directions are arranged on the connecting protruding ring. The objects supported by the casters are connected in the threaded connection holes by bolts to realize the connection with the present invention. A straight section 552 is provided at both radial ends of the connecting convex ring. A limiting notch 553 extending along the horizontal direction is provided on the lower edge of the straight section. The upper end of the connecting plate is provided wi...

Embodiment 3

[0027] Embodiment three, the difference with embodiment two is:

[0028] Adjacent height adjustment pads are connected together by Belleville springs.

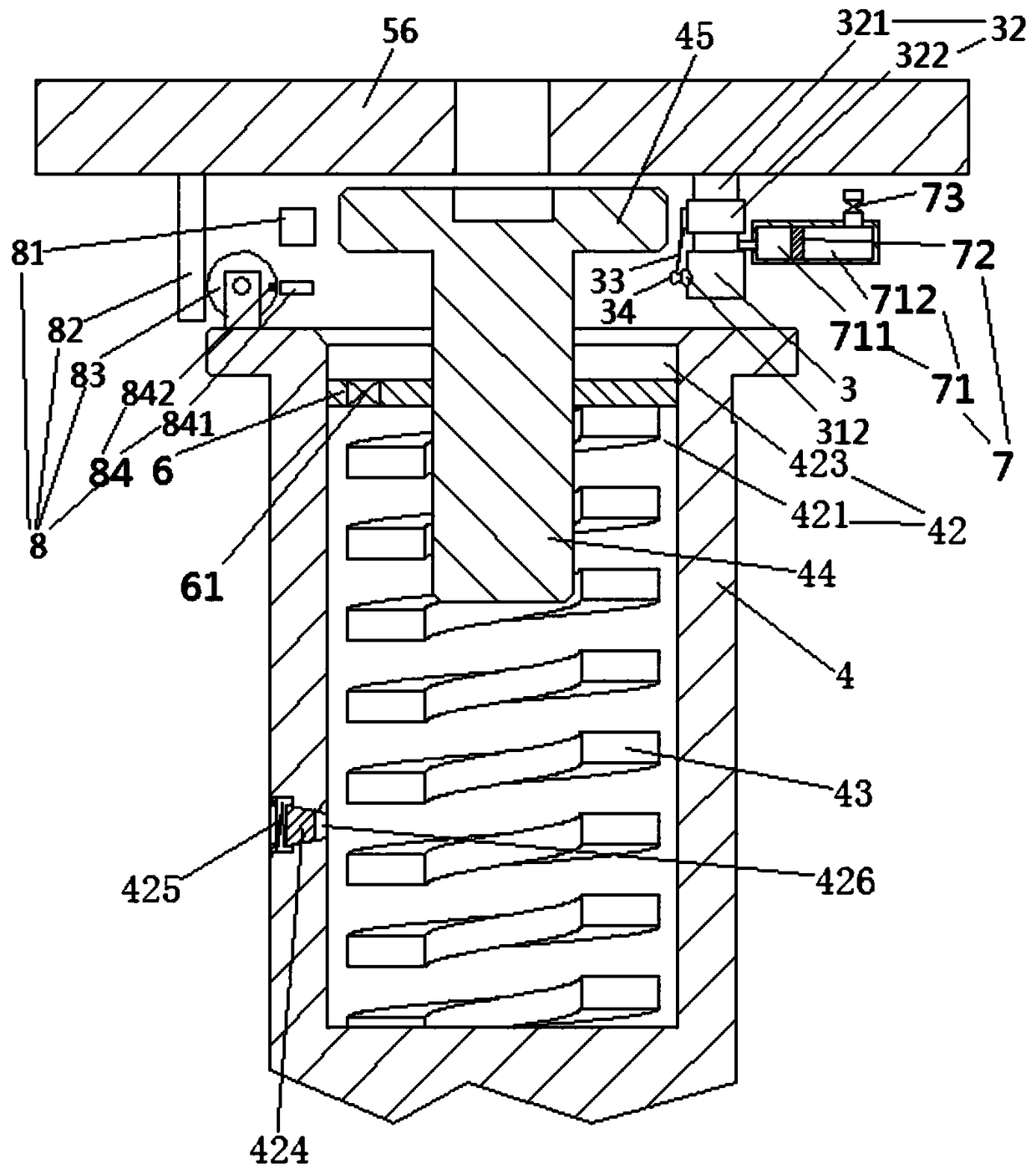

[0029] see image 3 , Figure 4 , Figure 5 and Figure 6 , the positioning rod 44 is fixedly connected with the compression plate 6 which is slidingly and sealingly connected in the spring installation hole 42 . The compression plate isolates a sealed fat storage chamber 421 and a spare fat storage bowl 423 above the fat storage chamber in the spring installation hole. The damping spring 43 is located in the sealed grease storage chamber and supported on the lower surface of the compression plate. The side wall of the spring mounting hole is provided with an oil outlet window 426 penetrating through the sealed grease storage chamber. The oil outlet window is provided with a sealing plug 424 and a window closing spring 425 that drives the sealing plug to move toward the sealed grease storage chamber to seal the oil outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com