Slow vibration caster assembly

A caster and assembly technology, applied in the direction of casters, wheels, vehicle parts, etc., can solve the problems of poor anti-vibration effect of casters, and achieve the effect of good anti-vibration effect and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

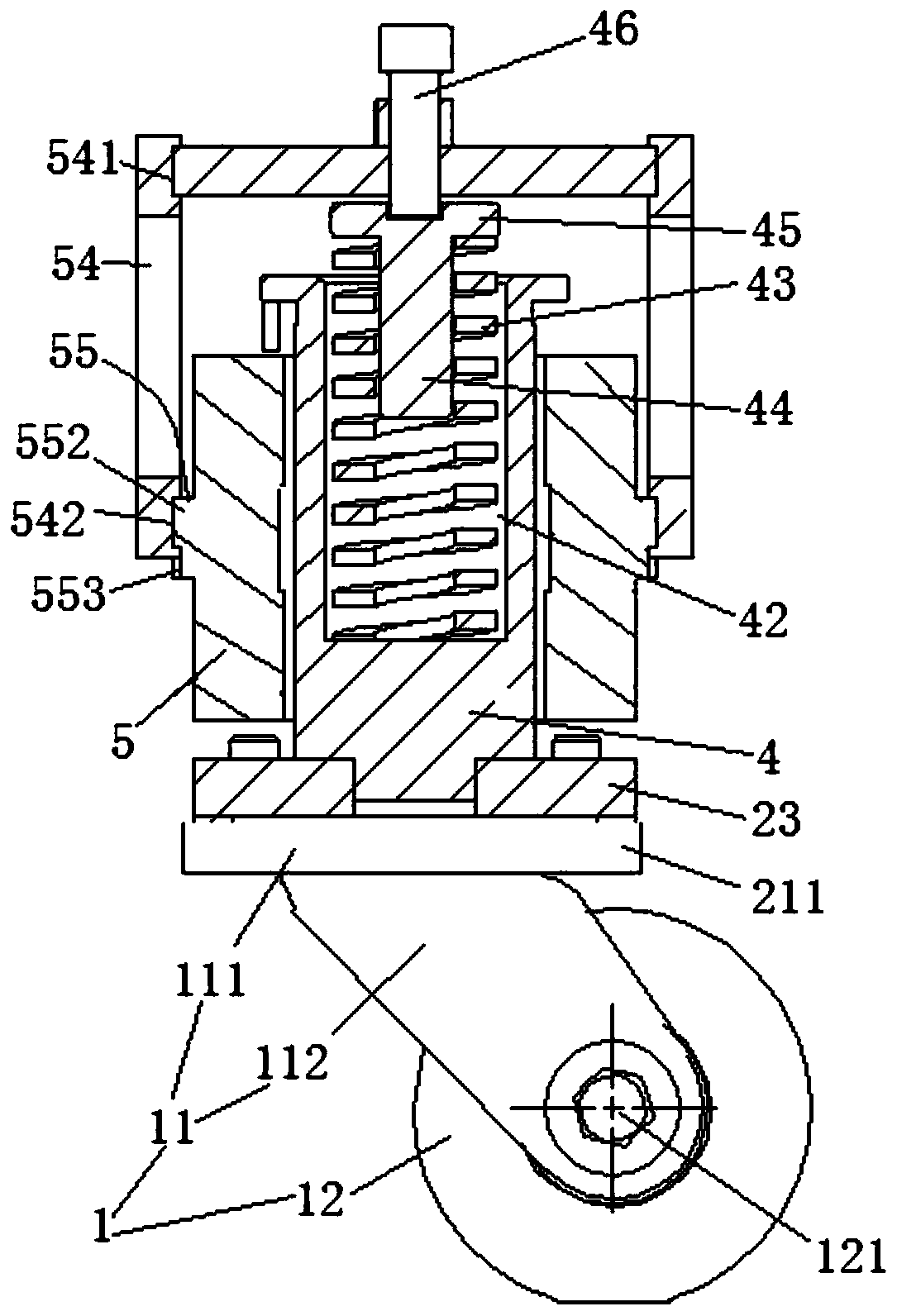

[0020] Embodiment one, see figure 1 with figure 2 , a vibration-slowing caster assembly, including a caster 1 and a caster connection structure.

[0021] The caster 1 includes a wheel frame 11 and a disc-shaped plastic roller 12 . The wheel frame 11 includes a horizontal connecting rod 111 and two vertical connecting rods 112 whose upper ends are connected together with the horizontal connecting rod. The disc-shaped plastic roller 12 is located between the two vertical and horizontal connecting rods and is connected together with the two vertical connecting rods by the axle 121 .

[0022] The caster connection structure includes a caster connection seat 23 . The transverse connecting rod 111 of the rubber wheel is connected to the below of the caster connecting seat through the connecting screw rod 24 . A central post 4 is provided on the caster connection seat. A connecting sleeve 5 is sheathed on the central column. The connecting sleeve is also provided with two conn...

Embodiment 2

[0024] Embodiment two, the difference with embodiment one is:

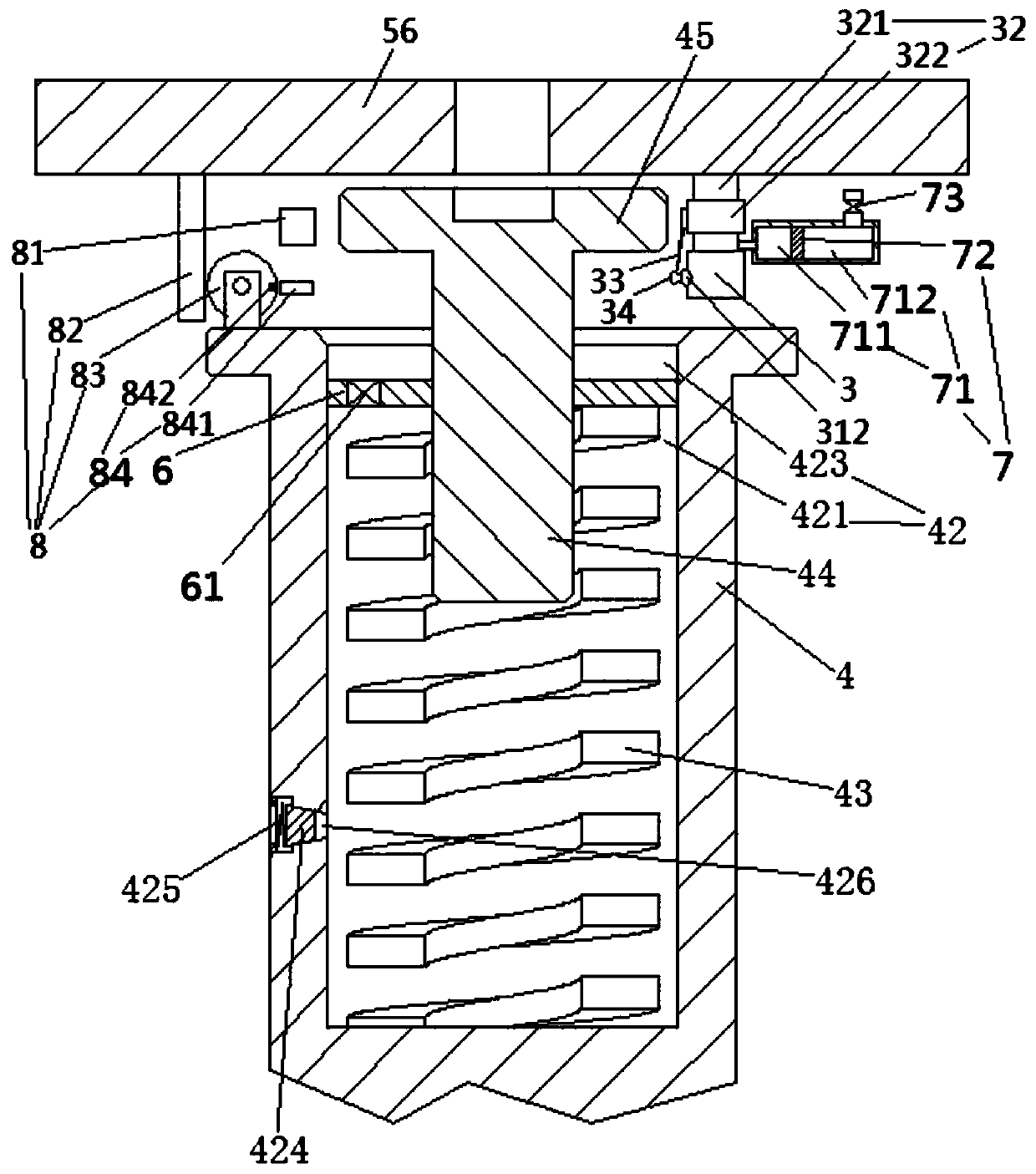

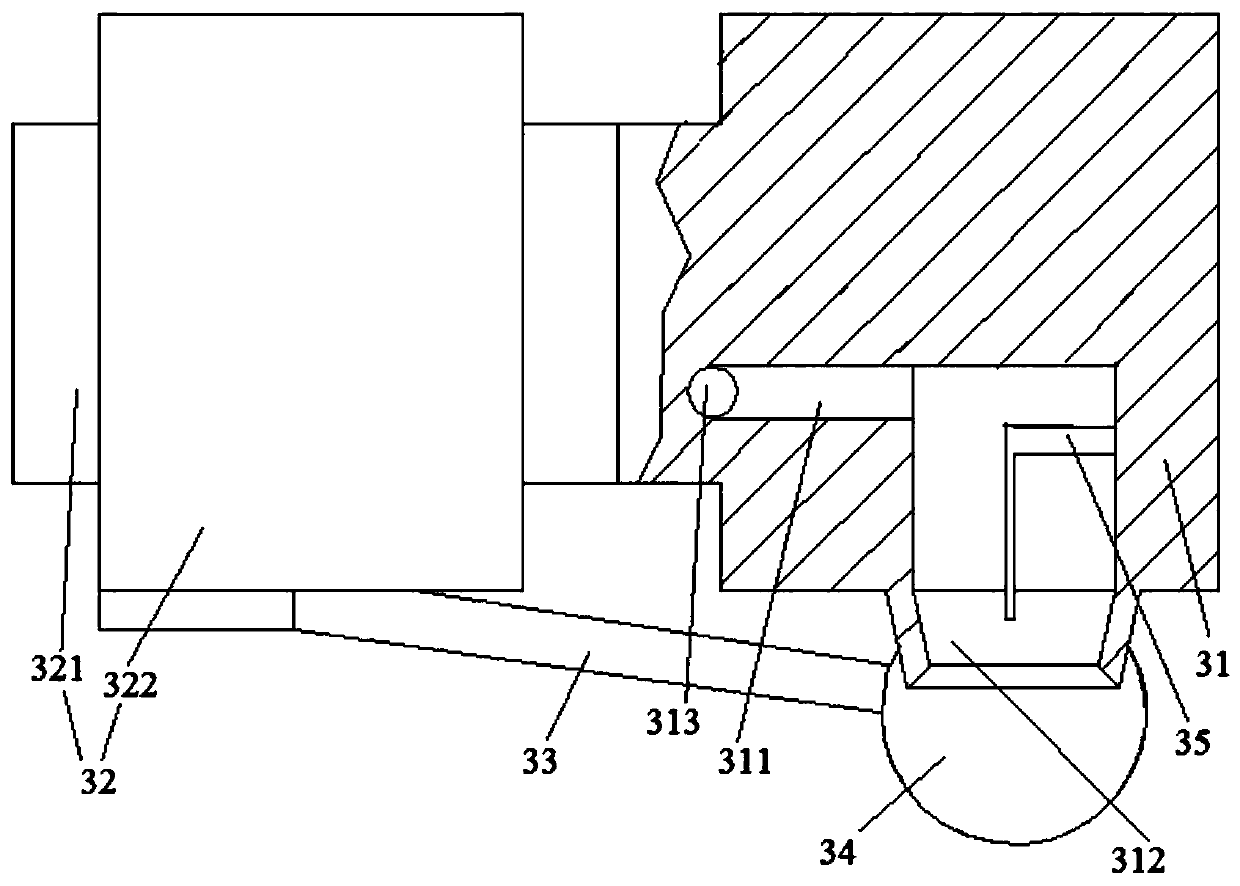

[0025] see image 3 , Figure 4 with Figure 5 The positioning rod 44 is fixedly connected with the compression plate 6 which is slidingly and sealingly connected in the spring installation hole 42 . The compression plate isolates a sealed fat storage chamber 421 and a spare fat storage bowl 423 above the fat storage chamber in the spring installation hole. The damping spring 43 is located in the sealed grease storage chamber and supported on the lower surface of the compression plate. The side wall of the spring mounting hole is provided with an oil outlet window 426 penetrating through the sealed grease storage chamber. The oil outlet window is provided with a sealing plug 424 and a window closing spring 425 that drives the sealing plug to move toward the sealed grease storage chamber to seal the oil outlet window. The compression plate is provided with a one-way valve 61 on the compression plate that opens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com