Steel rail defect depth detection method based on magnetic flux leakage detection device

A technology for magnetic flux leakage detection and defect depth, applied in the field of measurement technology and instruments, can solve problems affecting workpiece grinding and replacement, and achieve the effect of accurate damage and serious damage and accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

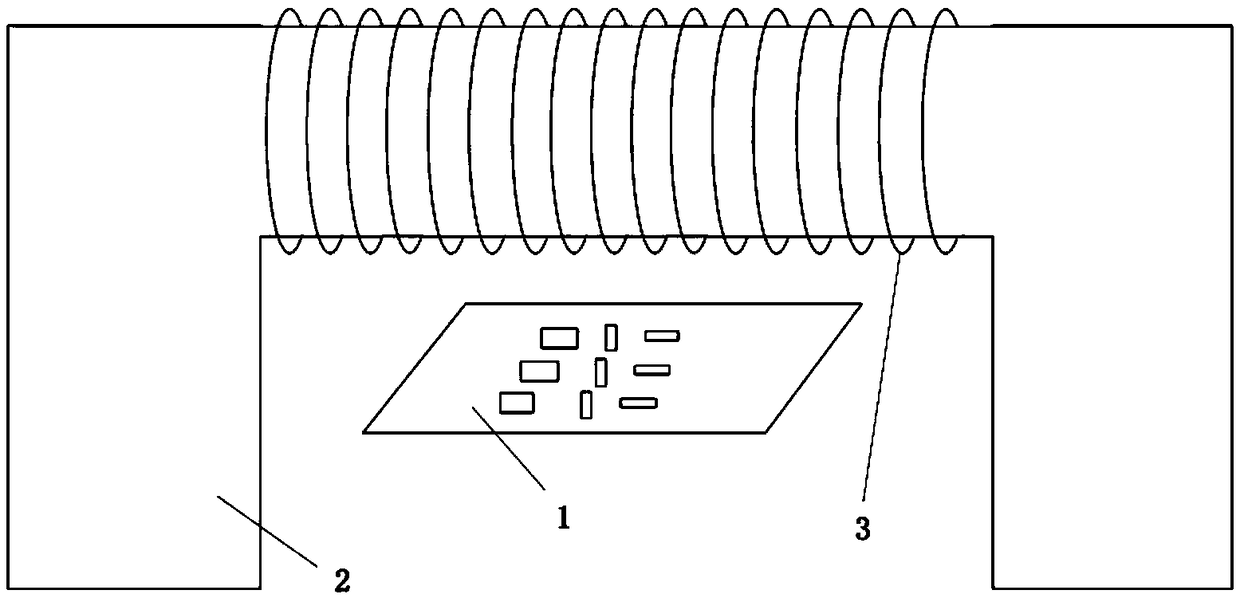

[0020] The invention discloses a method for detecting the depth of rail defects based on a magnetic flux leakage detection device, such as figure 1 As shown, the magnetic flux leakage detection device includes a housing, a yoke, an excitation coil, a Hall sensor array, a first caster and a second caster;

[0021] Both the first caster and the second caster are wide wheels, which are respectively arranged on the lower end surface of the housing, so that the housing can roll on the rail to be detected;

[0022] The yoke, the excitation coil, and the Hall sensor array are all arranged in the housing, wherein the yoke is in an inverted U shape, the excitation coil is wound on it, and the excitation coil is connected to an external power supply. The yoke is used to send a magnetic signal toward the rail to be detected when the excitation coil is energized; the Hall sensor array is arranged in the yoke and parallel to the rail to collect magnetic flux leakage signals;

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com