Frame structure, liquid crystal module and assembly method of liquid crystal module

A technology of liquid crystal module and assembly method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high glue requirements, difficult manual operation, complicated pasting process, etc., achieve simple and flexible assembly method, improve solid The effects of connection reliability and protective glass properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

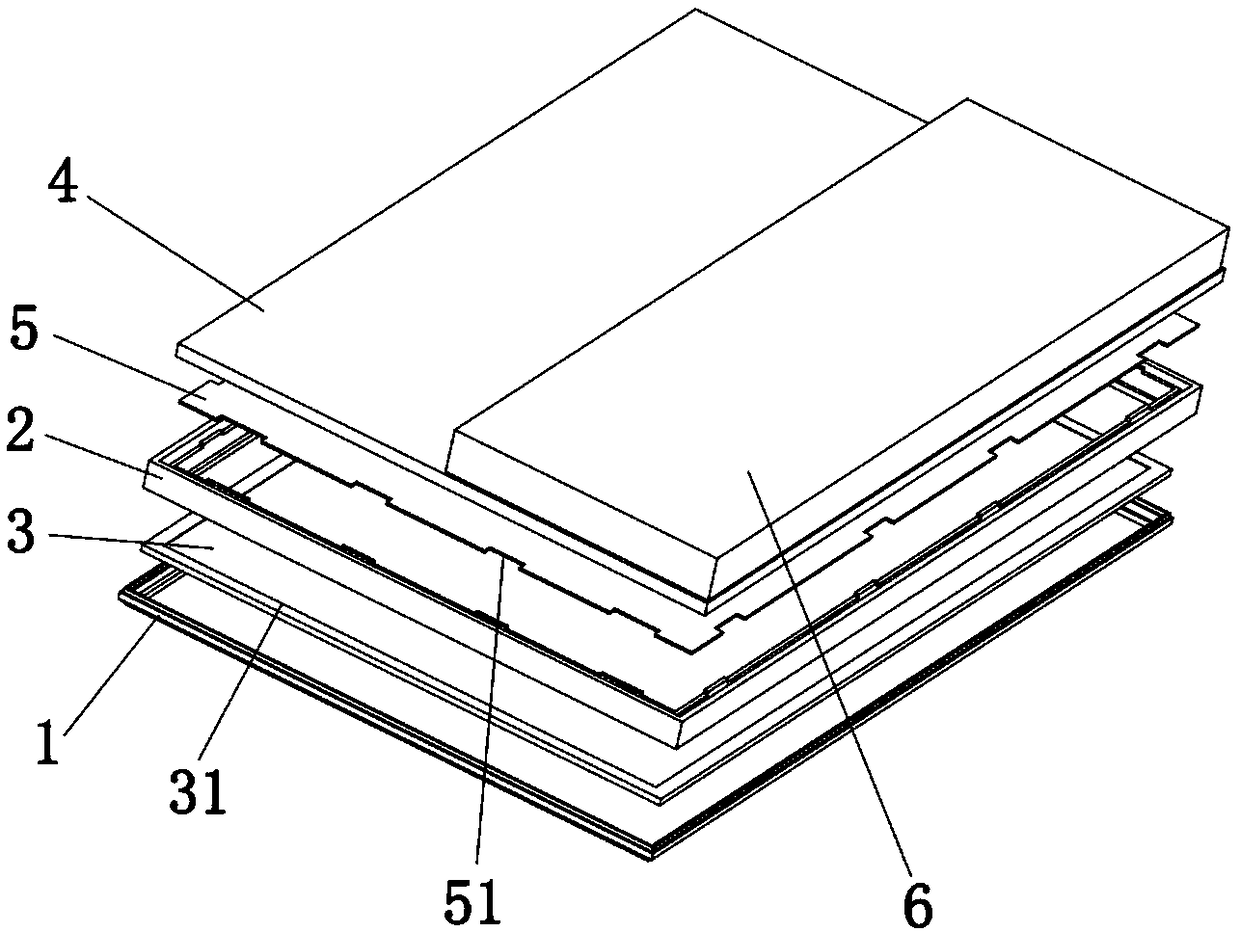

[0051] This embodiment provides a frame structure and a liquid crystal module with the frame structure, which can be used in the fields of liquid crystal displays, mobile phones, tablet computers or other electronic display screens. The liquid crystal module provided in this embodiment has a split frame structure, which can conveniently and flexibly change the color of the frame, reduce costs, and meet different customer needs.

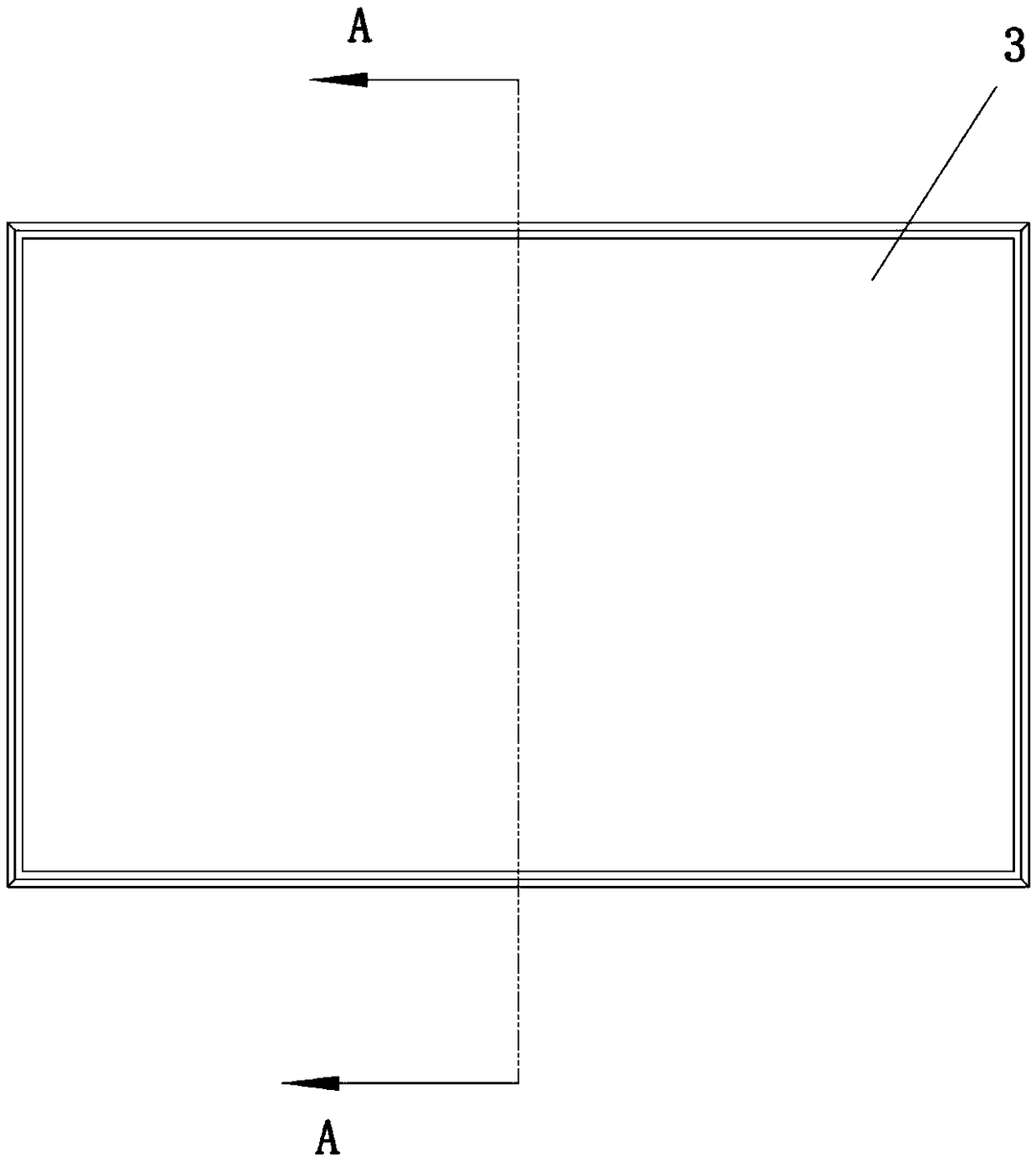

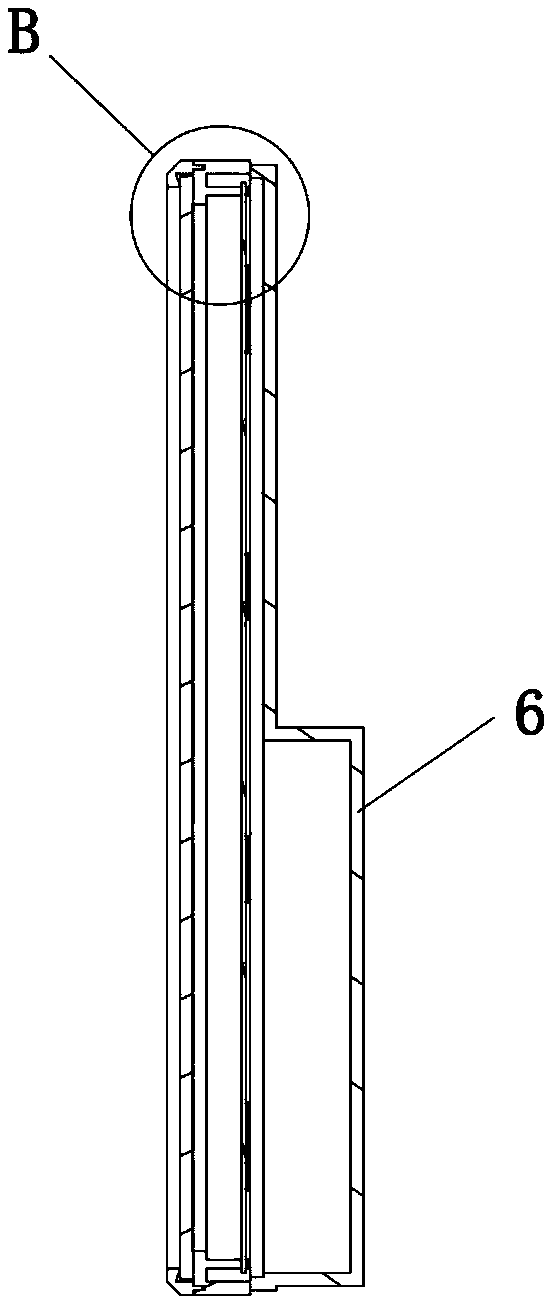

[0052] Such as Figure 1-Figure 10 As shown, this embodiment provides a frame structure, including a front frame 1 and a middle frame 2 . Wherein, the front bumper frame 1 is framed around the glass panel 3, and hooked on the front portion of the glass panel 3, and the front bumper frame 1 is in soft contact with the front portion of the glass panel 3. One end of the middle frame 2 is attached to the back of the glass panel 3 , snapped to the front frame 1 , and presses the glass panel 3 together, and the other end is connected to the back panel 4 . ...

Embodiment 2

[0063] This embodiment provides a method for assembling a backlight module, which is simple, flexible and easy to implement.

[0064] A method for assembling a liquid crystal module, comprising the following steps:

[0065] A front bumper frame 1 with a preset color and a middle frame 2 with a preset color are provided.

[0066] Specifically, providing the front bumper frame 1 with a preset color includes making the front bumper frame 1 through injection molding to achieve a preset high-gloss effect, or spraying the surface of an injection-molded semi-finished product to make the front bumper frame 1 . This process can be carried out independently without covering other components, saving labor costs.

[0067] Providing the middle frame 2 with a preset color includes: making the middle frame 2 through injection molding to achieve a high-gloss effect, or making the middle frame 2 through ordinary injection molding to achieve a matte effect and then spraying the surface to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com