Micro-inertial measuring component structure to resist high overload

A technology of micro-inertial measurement and component structure, which is applied in directions such as navigation through velocity/acceleration measurement, can solve problems such as rigid displacement, uneven potting and filling, and wiring detached from pads, etc., to reduce assembly complexity, Improving the reliability of fixed connection and satisfying the effect of miniaturization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

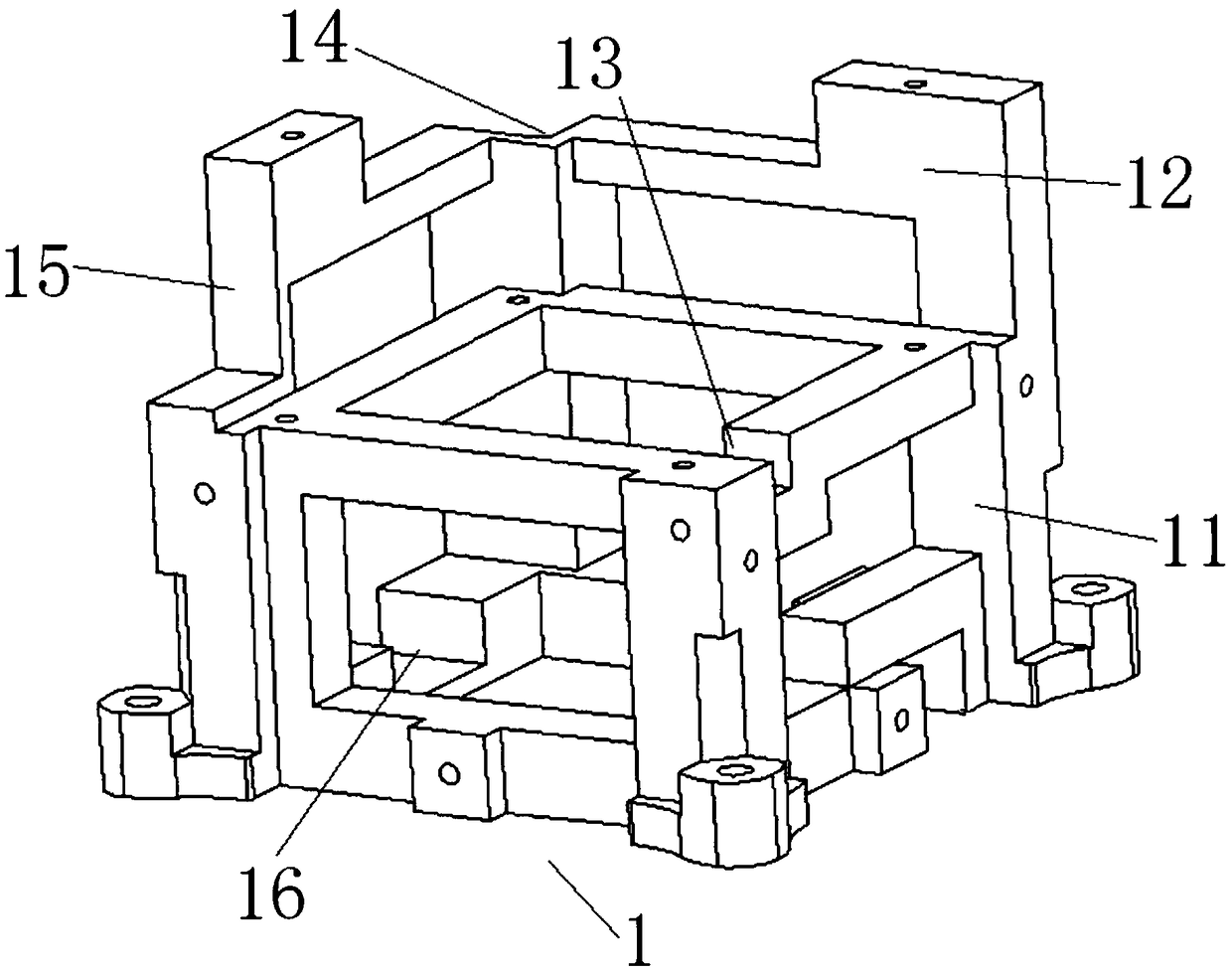

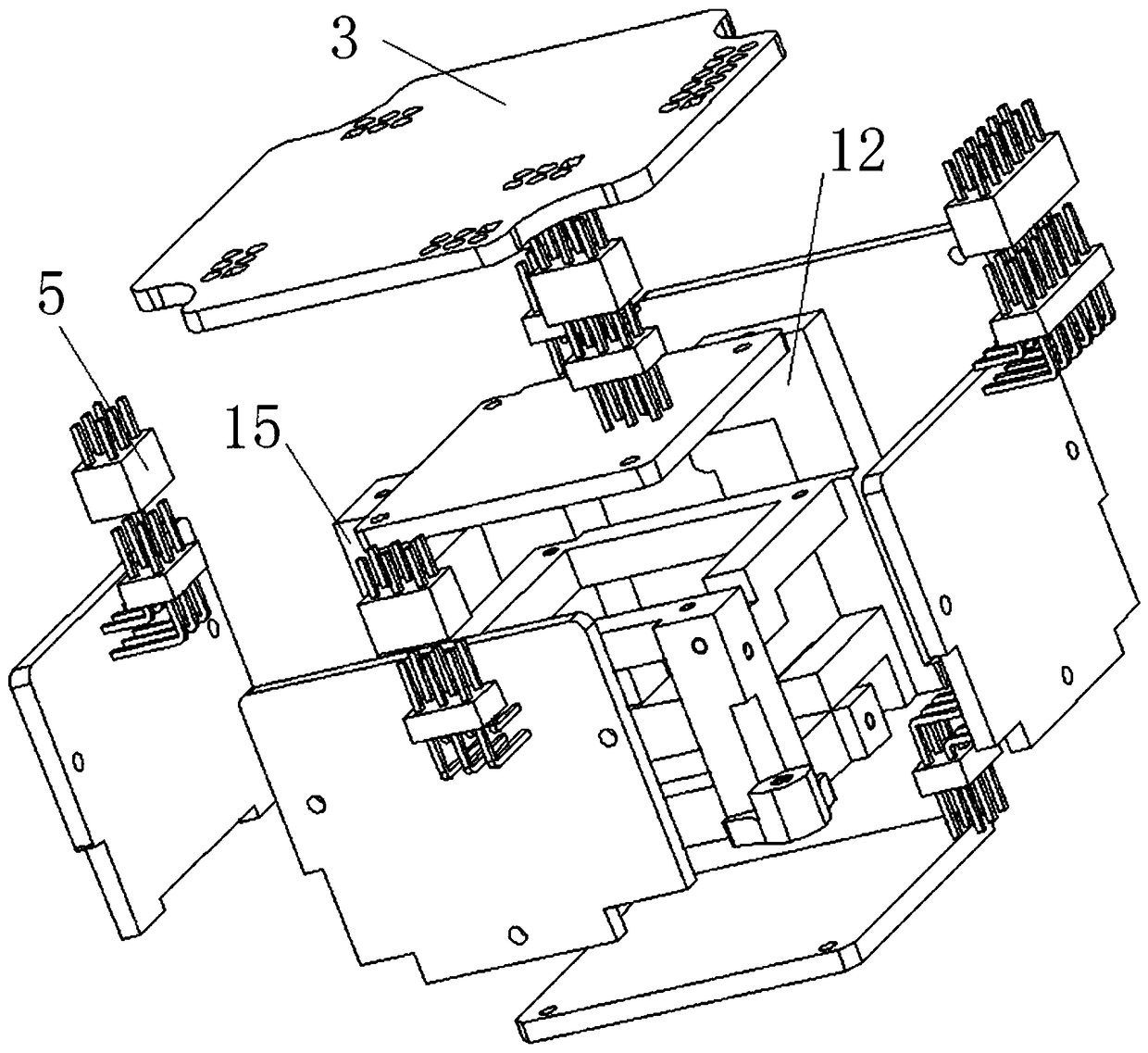

[0028] Such as figure 1 , figure 2 As shown, in this patent, the anti-overload support structure 1 of the micro-inertial measurement component is designed as a hollow structure in the middle of an approximate hexahedron, and three orthogonal axial sides 11 are used for penetration treatment, and a boss 12 design is added to the top plane, so the structure has a total of 7 flat surfaces for mounting circuit boards. Among them, six mutually orthogonal hollow planes are used to install MEMS inertial sensor circuit board 2, the boss 12 on the top can be used to install core controller circuit board 3, and the space inside the frame is filled with potting material to protect electronic devices. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com