Collision bumper for optical mechanical module, and movable lenses

An opto-mechanical module and lens movement technology, applied in the focusing device of a projector, the focusing device of a camera, a projection device, etc., can solve the problems of increasing the assembly complexity of the opto-mechanical module and the volume of the opto-mechanical module, and reduce the assembly complexity. The effect of stability, space saving and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

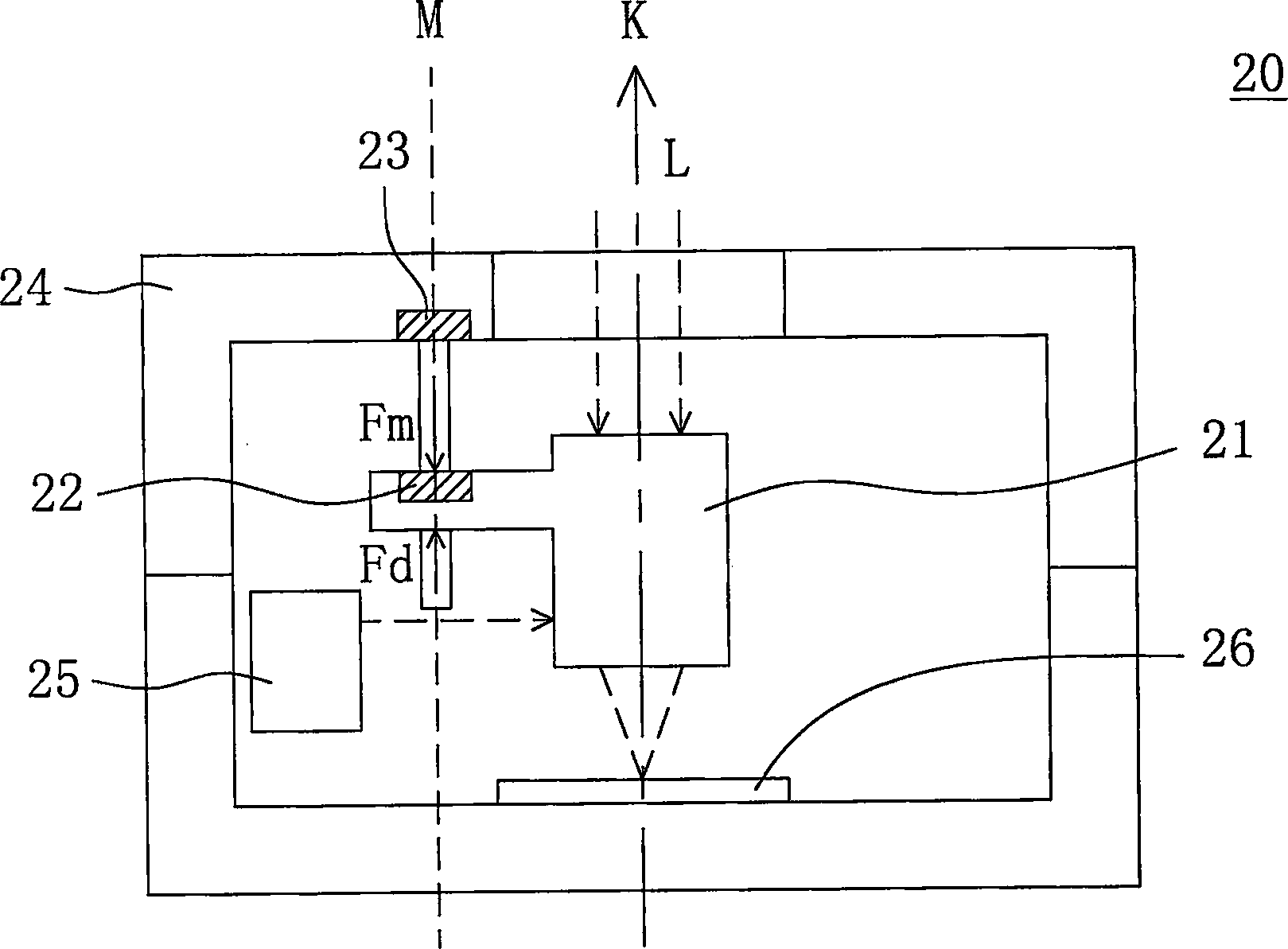

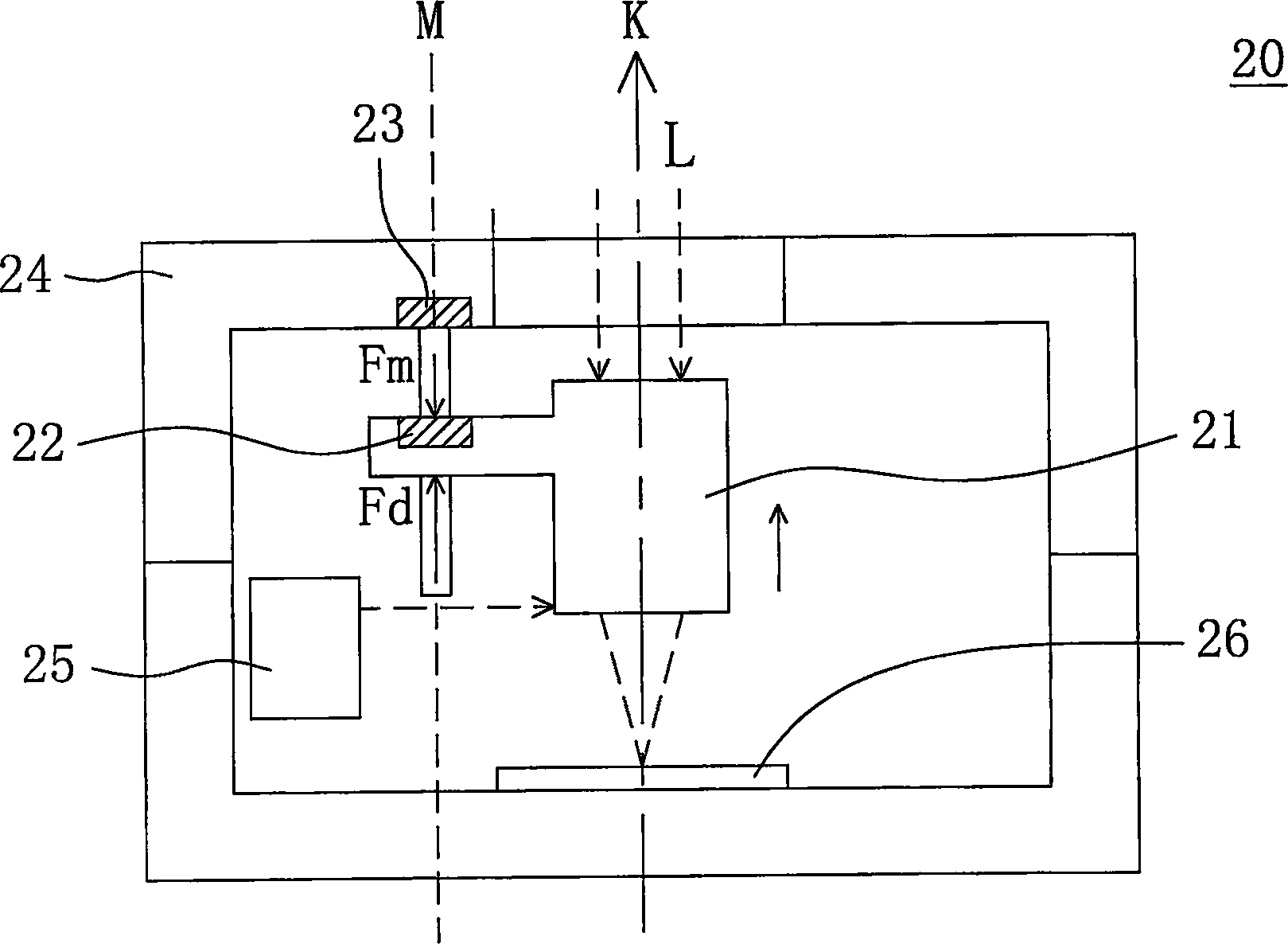

[0031] In order to make the above-mentioned purpose, features, and advantages of the present invention more obvious and easy to understand, a preferred embodiment is given below, and the implementation of the optical-mechanical module and its lens moving buffer device of the present invention will be described in detail below in conjunction with the accompanying drawings as follows,

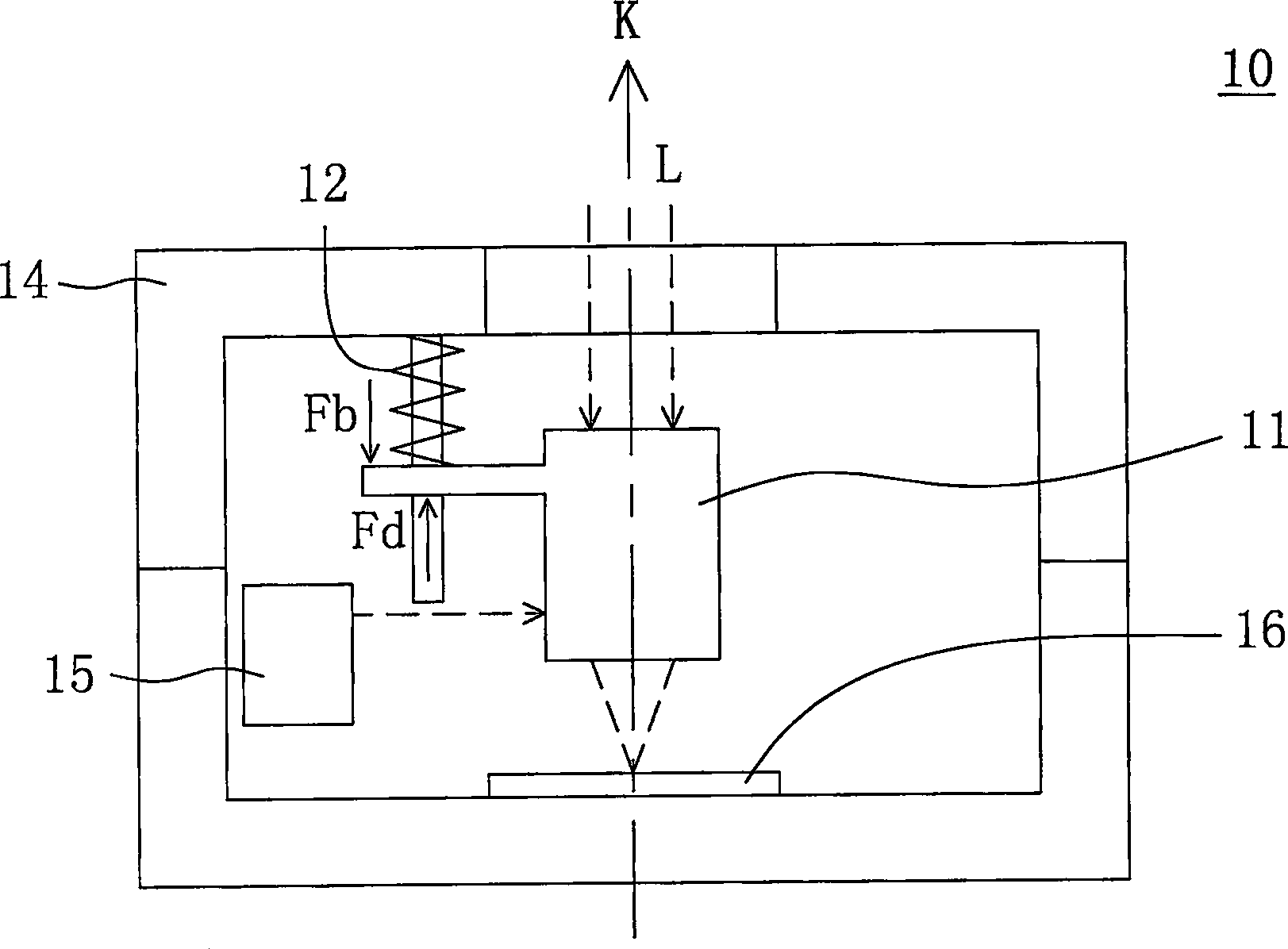

[0032] The present invention proposes a lens movement buffer device used in an optical-mechanical module, which is used to replace the traditional contact spring mechanism to provide the buffer force required for lens movement. In addition, based on the same operating principle, the present invention can be applied to optical lens modules of various digital cameras and mobile phones with digital camera functions.

[0033] Please refer to Figure 2A , which shows a schematic cross-sectional view of an optical-mechanical module according to a preferred embodiment of the present invention. The opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com