Heat exchange device of universal-type fermentation tank

A technology of heat exchange device and fermenter, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biochemical cleaning device, etc. Problems such as heat exchange and cooling efficiency, poor heat exchange effect of fermentation tanks, etc., to achieve the effect of improving air circulation efficiency, reducing heat exchange costs, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

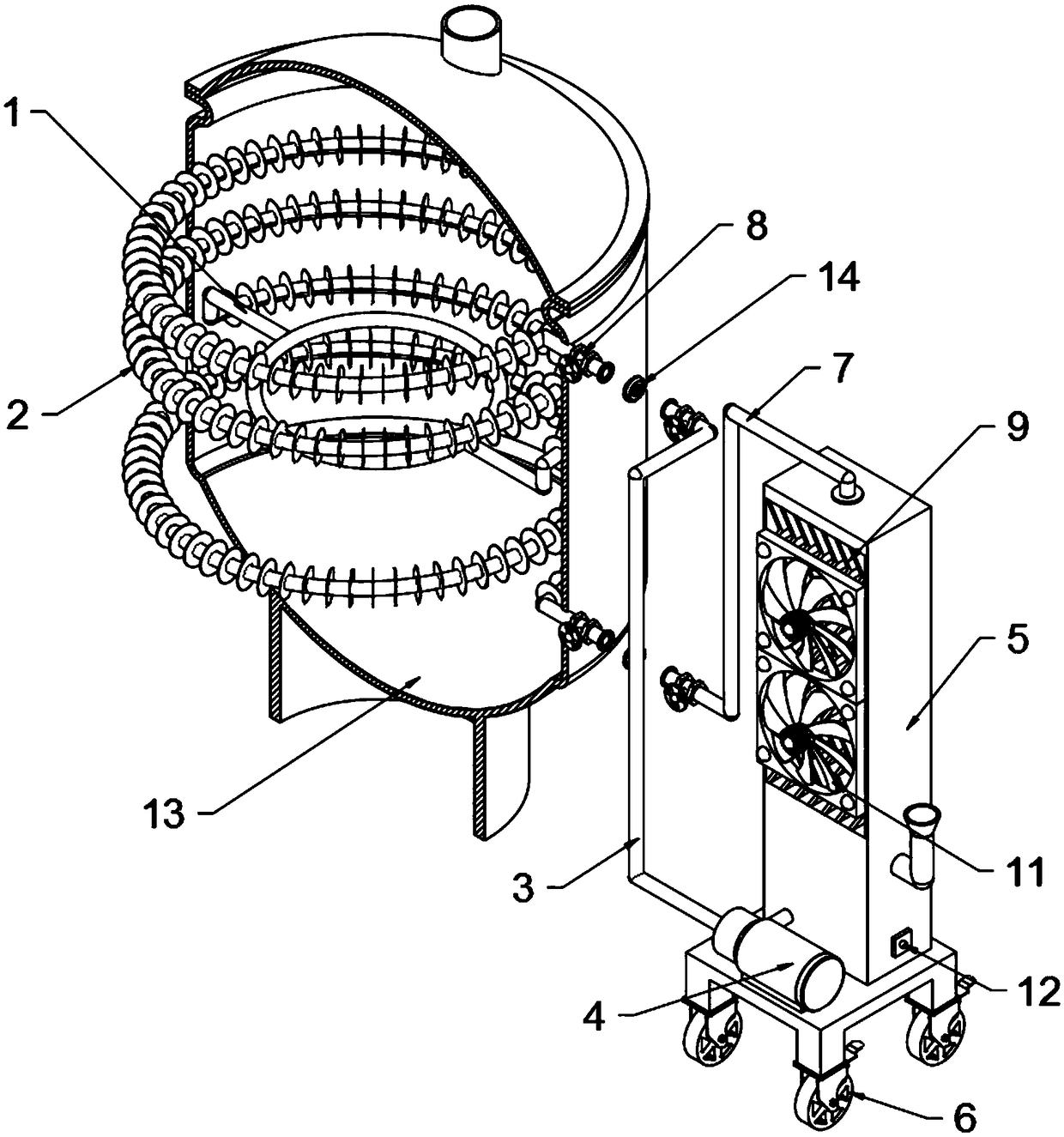

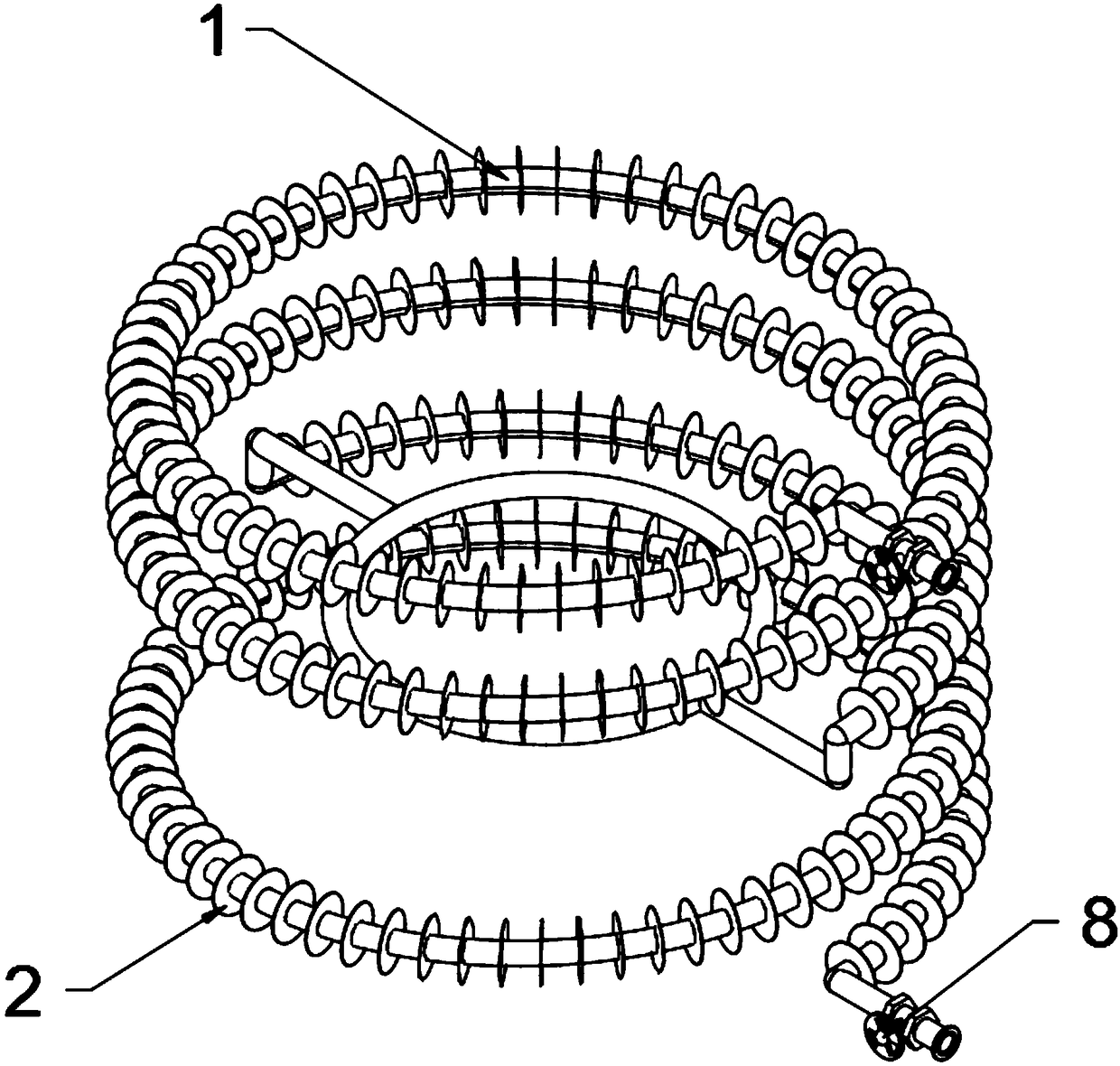

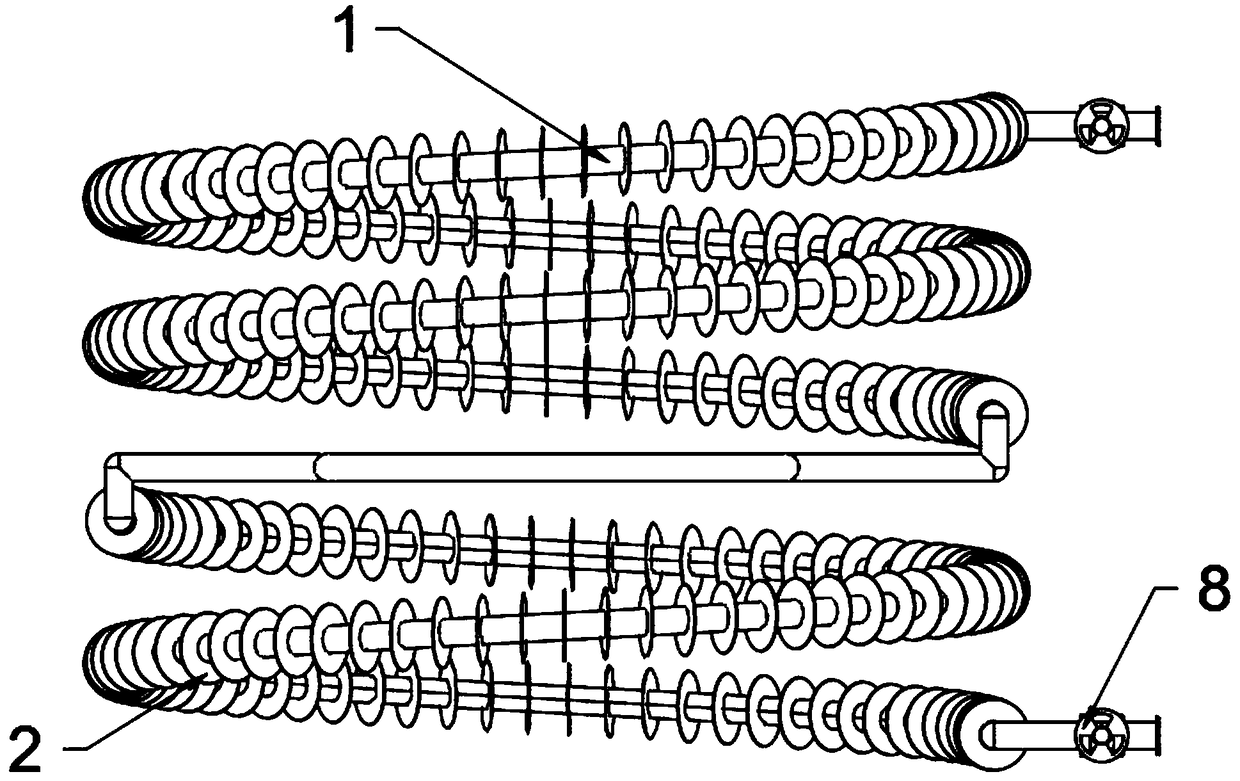

[0034] as attached figure 1 to attach Figure 9 Shown:

[0035] The invention provides a general-purpose fermenter heat exchange device, which includes a heat exchange tube 1, a heat exchange fin 2, a liquid inlet pipe 3, a pump body 4, a cooling frame 5, a liquid storage chamber 501, a universal wheel 6, a liquid outlet Pipe 7, valve 8, cooling plate 9, cooling fin 10, diversion fan 11, power switch 12, fermentation tank 13 and pipe clamp 14; the heat exchange tube 1 is installed inside the fermentation tank 13, and the heat exchange tube 1 The outlet port and the inlet port are located outside the fermentation tank 13, and the heat exchange fins 2 are installed on the heat exchange tube 1; one end of the liquid inlet pipe 3 is located at the bottom of the cooling frame 5, and the liquid inlet pipe 3 is connected to the pump body 4; The pump body 4 is installed at the bottom of the cooling frame 5, and the pump body 4 is connected to the liquid storage cavity 501 at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com