Steel structure assembled external wall system

A prefabricated, steel structure technology, applied in the direction of walls, building components, work accessories, etc., can solve the problems of wasting building materials and wasting labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

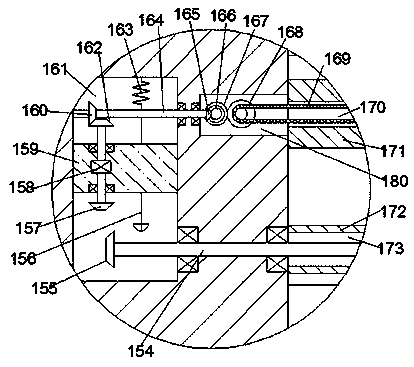

[0010] like Figure 1-Figure 2 As shown, a steel structure assembled exterior wall system of the present invention includes a main body 100, the main body 100, an iron plate inlet 129 is opened on the front end surface of the main body 100, and the iron plate inlet 129 There are first grooves 124 symmetrically opened on the left and right side end walls of the left and right sides, and the first grooves 124 are equipped with a rotating mechanism. On the bottom wall of the groove 124, a first bevel gear 127 is fixed on the top end surface of the rotating wheel 119, and a first fixed block 121 is fixed on the circumferential outer wall of the rotating wheel 119. The blocks 121 are evenly distributed in three groups, the first fixed block 121 is provided with a first sliding cavity 125, and a sliding plate 122 is provided for sliding in the first sliding cavity 125, and the sliding plate 122 is close to the side of the rotating wheel 119 A first spring 126 is elastically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com