Fixing frame for illuminating lamp in construction site

A technology for lighting lamps and construction sites, which is applied in the parts of lighting devices, lighting applications, lighting devices, etc., can solve the problems of lighting blockage, lights shaking, construction workers, and lack of light, and achieves the ability to prevent left and right shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

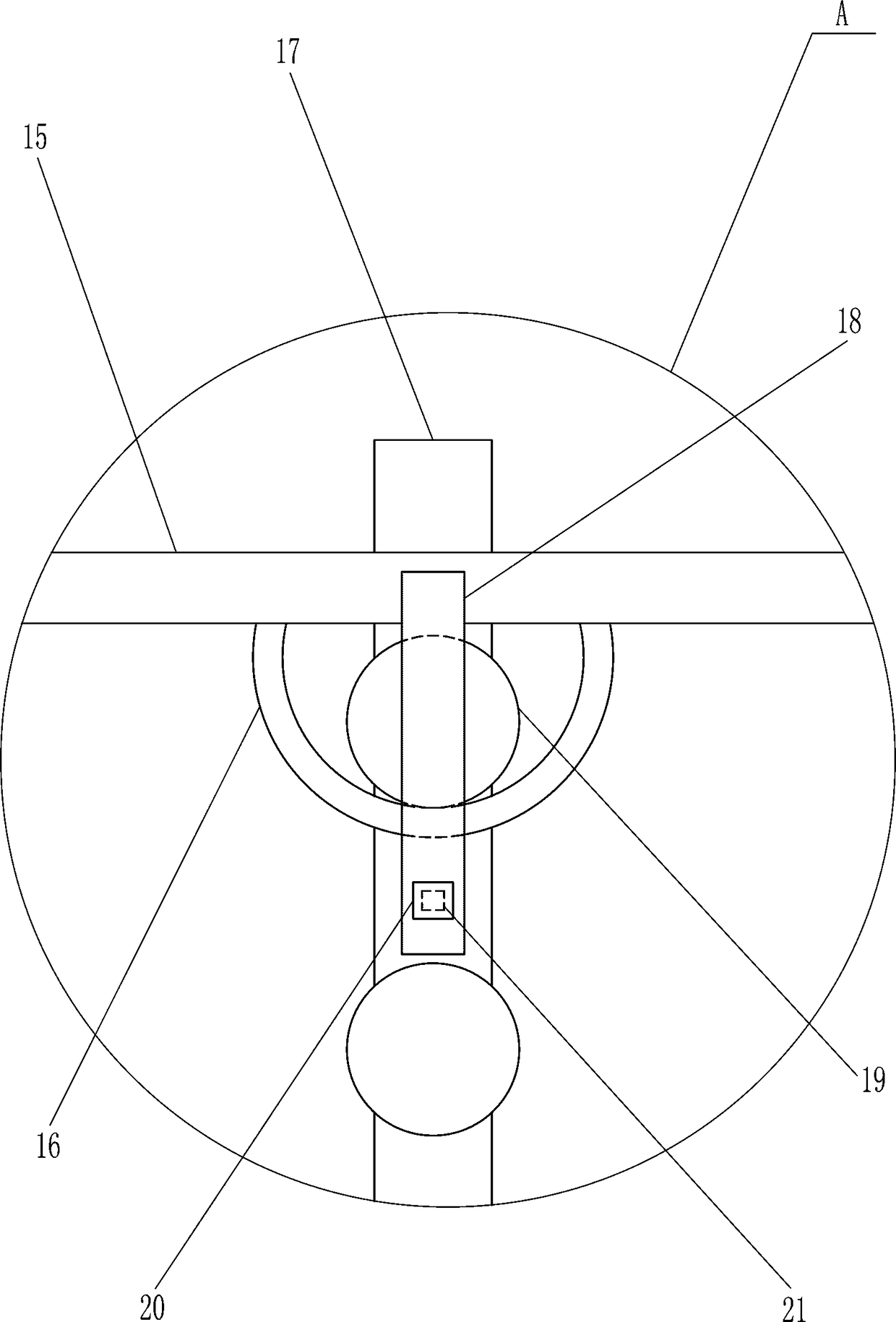

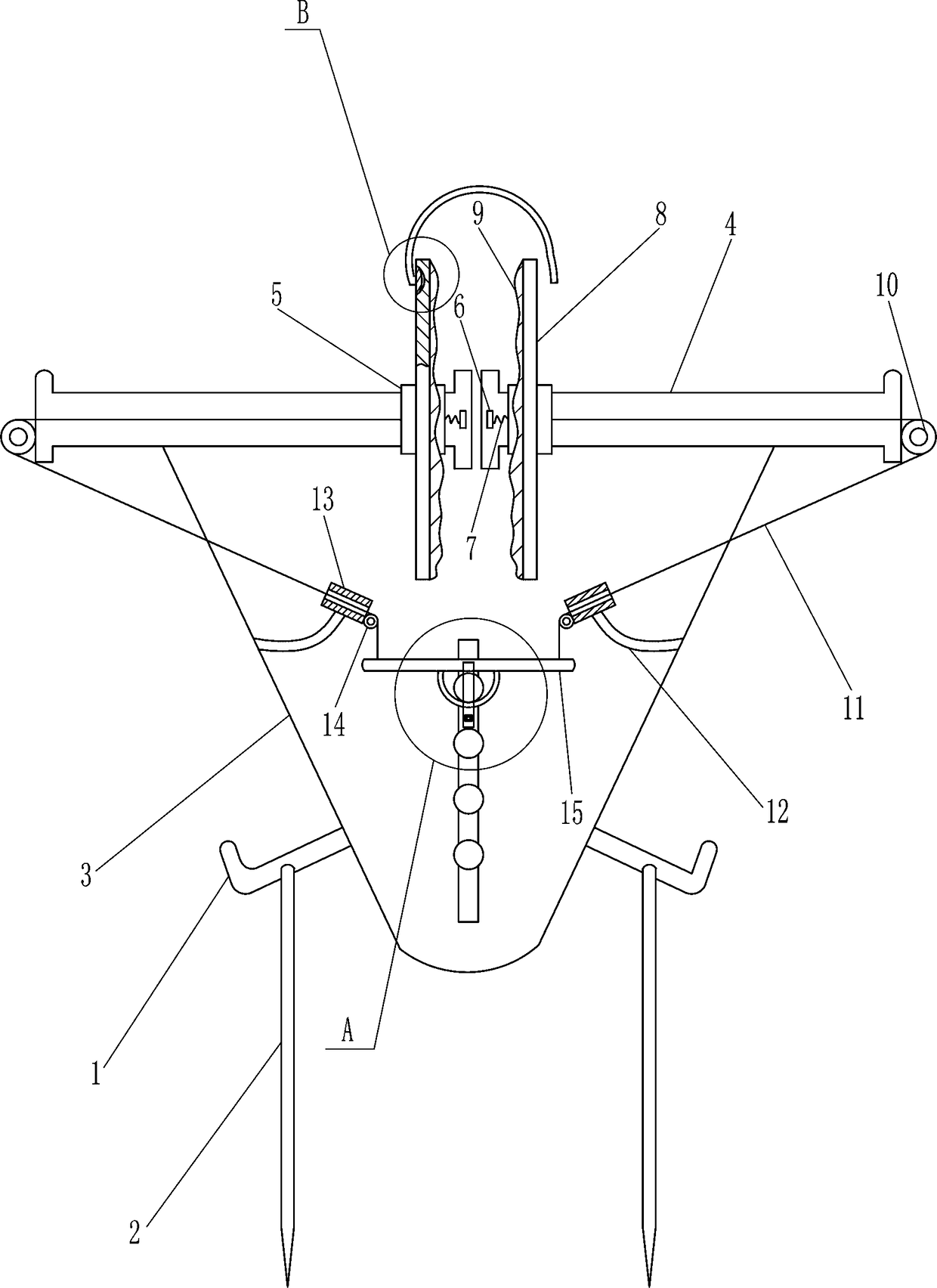

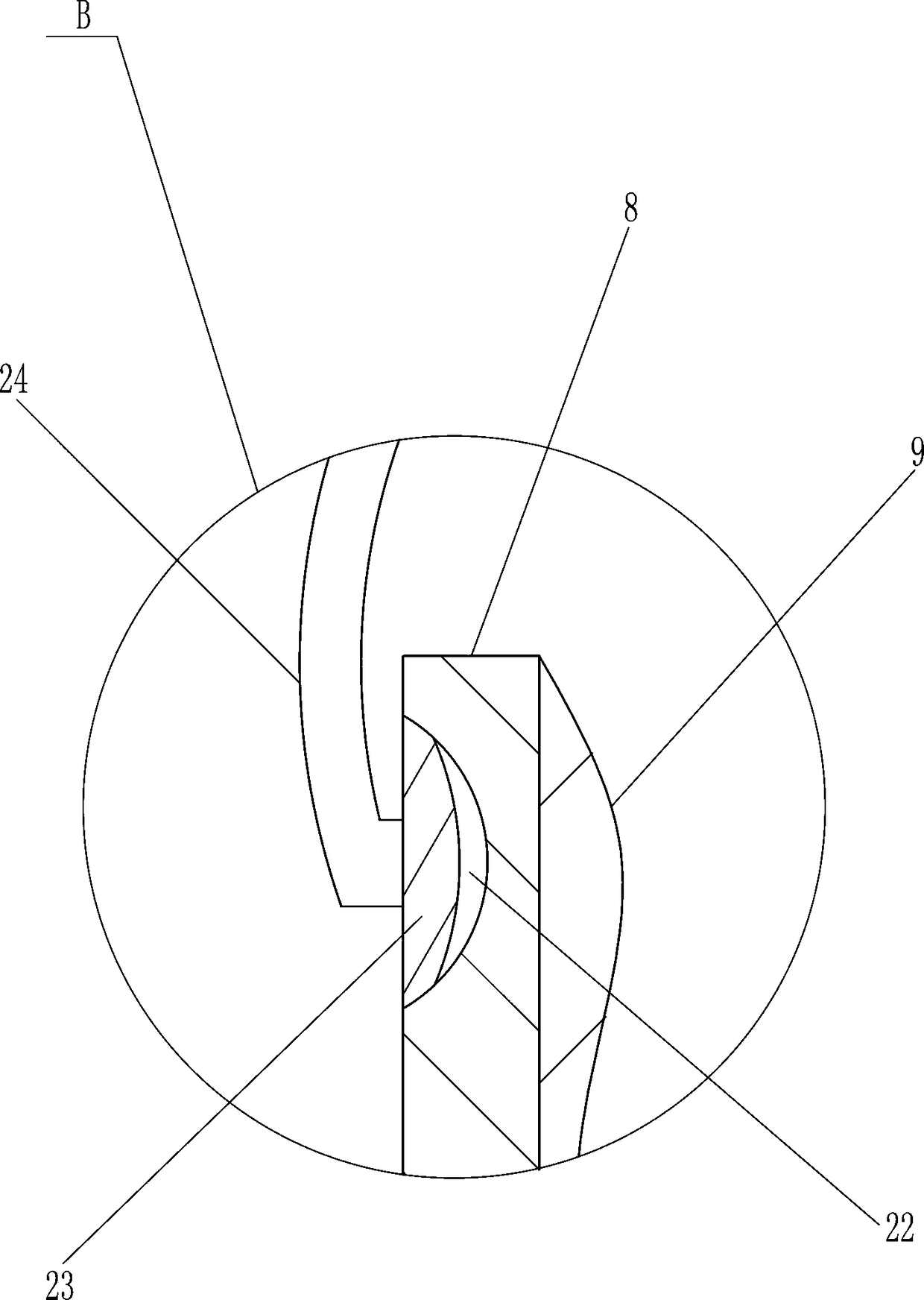

[0017] A fixing frame for construction site lighting fixtures, such as Figure 1-3 As shown, it includes a fixed rod 1, an insert rod 2, a mounting column 3, a slide rail 4, a slider 5, a bump 6, a spring 7, a splint 8, a cushion 9, a guide wheel 10, a pull cord 11, and a support rod 12 , guide sleeve 13, fixed pulley 14 and pull rod 15, the left and right sides bottoms of mounting column 3 are all connected with fixed rod 1, the front and rear sides of fixed rod 1 are all connected with insertion rod 2, the top left and right sides of mounting column 3 are all connected A slide rail 4 is connected, and a slide block 5 is slidably connected to the slide rail 4. The right part of the left slide rail 4 and the left part of the right slide rail 4 are connected with a bump 6, and the bump 6 and the slide block 5 A spring 7 is connected between them, a splint 8 is connected to the front side of the slider 5, a cushion 9 is connected to the right side of the left splint 8 and the le...

Embodiment 2

[0019] A fixing frame for construction site lighting fixtures, such as Figure 1-3 As shown, it includes a fixed rod 1, an insert rod 2, a mounting column 3, a slide rail 4, a slider 5, a bump 6, a spring 7, a splint 8, a cushion 9, a guide wheel 10, a pull cord 11, and a support rod 12 , guide sleeve 13, fixed pulley 14 and pull rod 15, the left and right sides bottoms of mounting column 3 are all connected with fixed rod 1, the front and rear sides of fixed rod 1 are all connected with insertion rod 2, the top left and right sides of mounting column 3 are all connected A slide rail 4 is connected, and a slide block 5 is slidably connected to the slide rail 4. The right part of the left slide rail 4 and the left part of the right slide rail 4 are connected with a bump 6, and the bump 6 and the slide block 5 A spring 7 is connected between them, a splint 8 is connected to the front side of the slider 5, a cushion 9 is connected to the right side of the left splint 8 and the le...

Embodiment 3

[0022] A fixing frame for construction site lighting fixtures, such as Figure 1-3 As shown, it includes a fixed rod 1, an insert rod 2, a mounting column 3, a slide rail 4, a slider 5, a bump 6, a spring 7, a splint 8, a cushion 9, a guide wheel 10, a pull cord 11, and a support rod 12 , guide sleeve 13, fixed pulley 14 and pull rod 15, the left and right sides bottoms of mounting column 3 are all connected with fixed rod 1, the front and rear sides of fixed rod 1 are all connected with insertion rod 2, the top left and right sides of mounting column 3 are all connected A slide rail 4 is connected, and a slide block 5 is slidably connected to the slide rail 4. The right part of the left slide rail 4 and the left part of the right slide rail 4 are connected with a bump 6, and the bump 6 and the slide block 5 A spring 7 is connected between them, a splint 8 is connected to the front side of the slider 5, a cushion 9 is connected to the right side of the left splint 8 and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com