A kitchen waste treatment device

A kitchen waste and treatment device technology, applied in filtration treatment, grain treatment, water/sewage multi-stage treatment, etc., can solve the problems of wasting resources, difficult to pulverize, easy to wear, etc., to ensure the pulverization effect and high pulverization efficiency. , The effect of increasing the oil load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

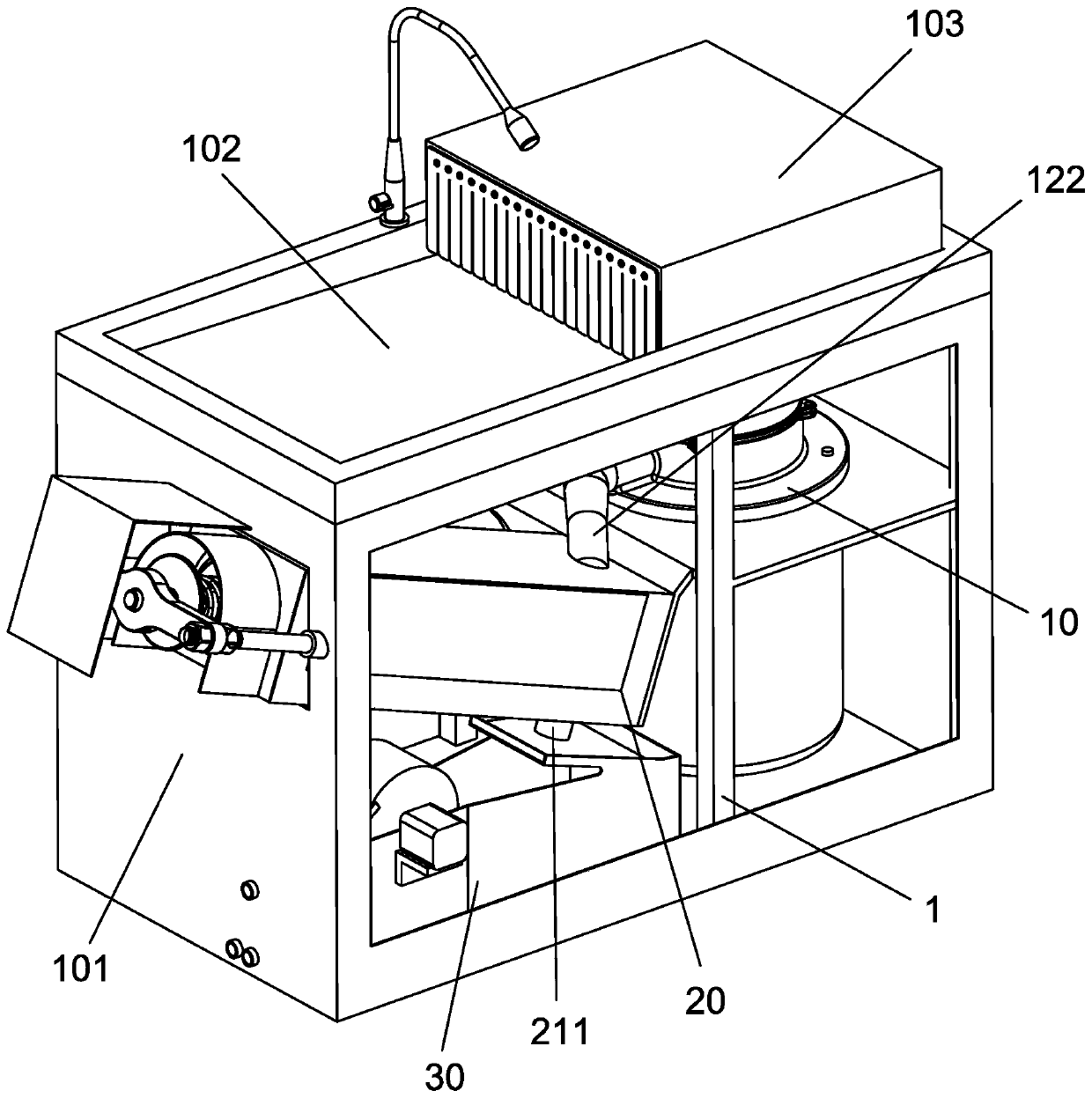

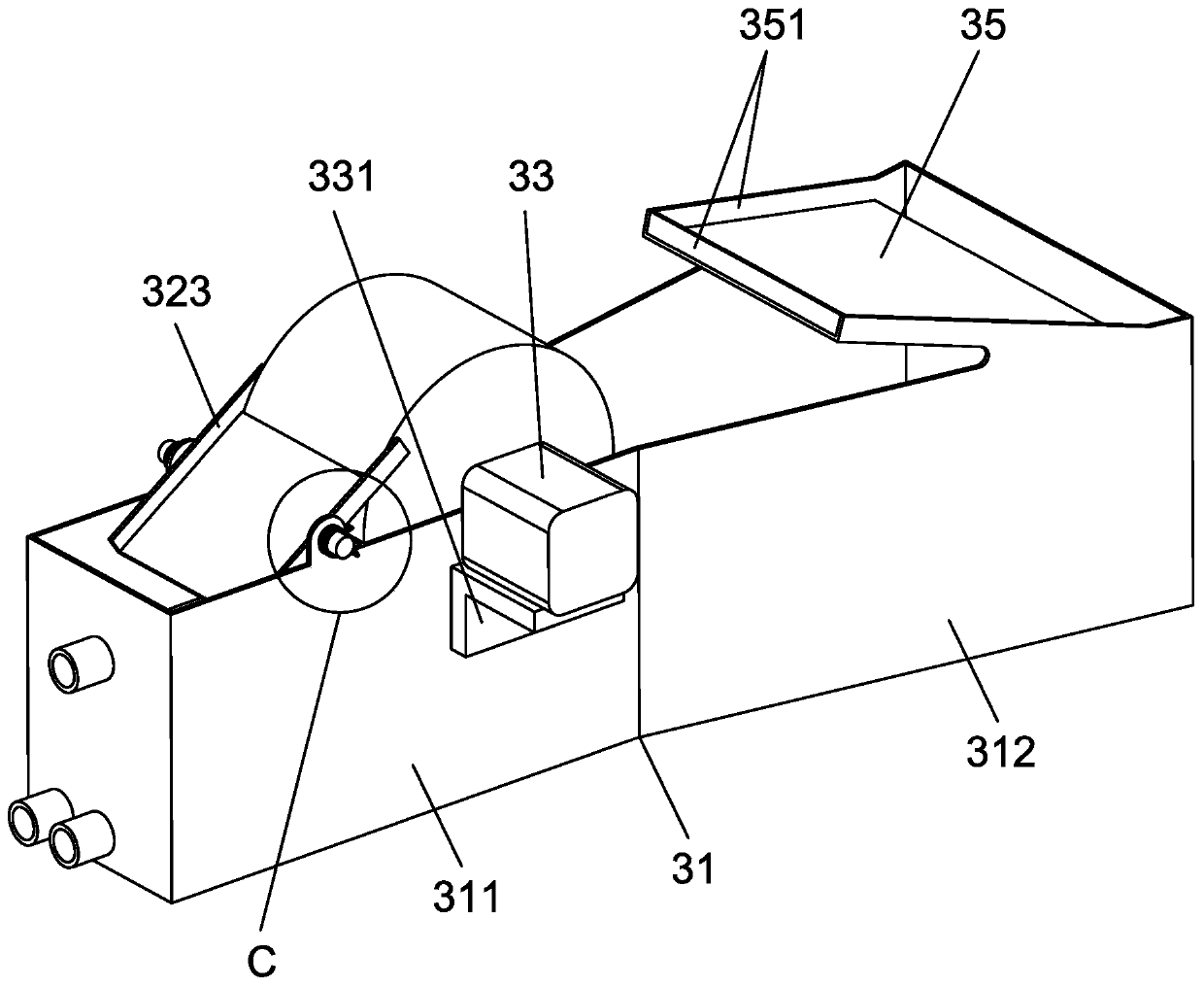

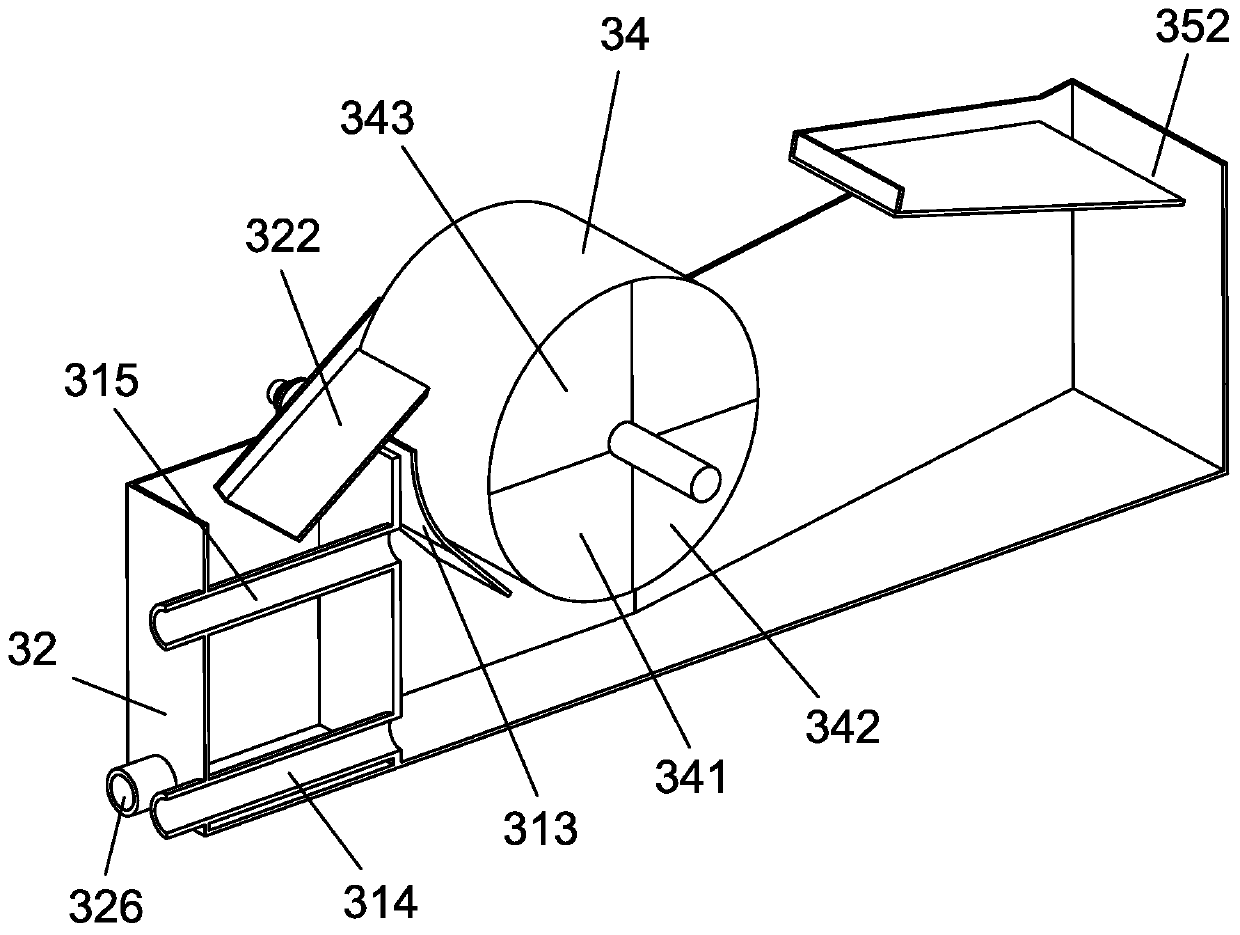

[0042] refer to Figure 1 to Figure 14 ,Such as Figure 1 to Figure 14 The shown kitchen waste processing device includes a frame 1, and a crushing device 10 is arranged on the frame 1 for crushing kitchen waste. The crushing device 10 discharges the crushed kitchen waste into a dehydration device 20 for dehydration. , the oil-water separation device 30 for oil-water separation of the dehydrated oil-water mixture, the oil-water separation device 30 includes a collection tank 31, and the collection tank 31 includes an oil extraction section 311 and a collection section 312, and the collection section 312 is towards the oil extraction section. The width of the section 311 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com